Double-crosslinked sodium alginate hydrogel and preparation method and application thereof

A technology of sodium alginate and double cross-linking, which is applied in the fields of medical science and prostheses, and can solve the problems of cumbersome preparation steps of double-network hydrogels, so as to ensure cell compatibility, improve anti-swelling performance, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

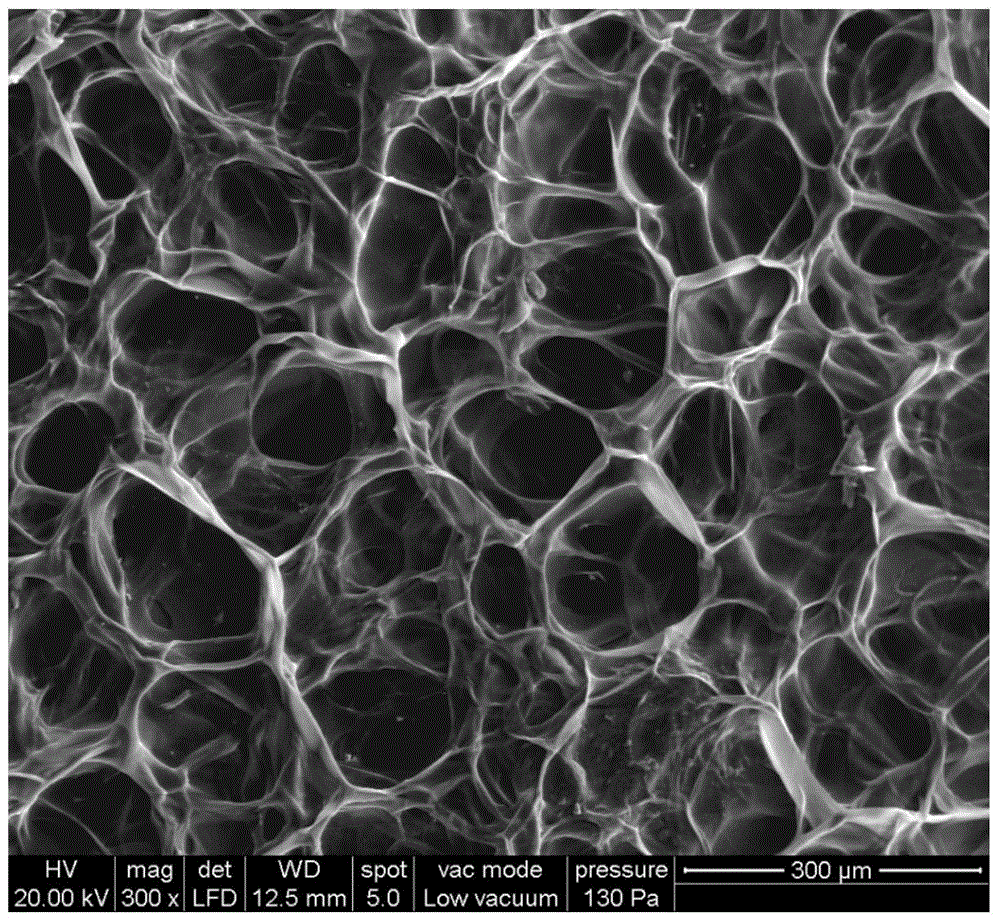

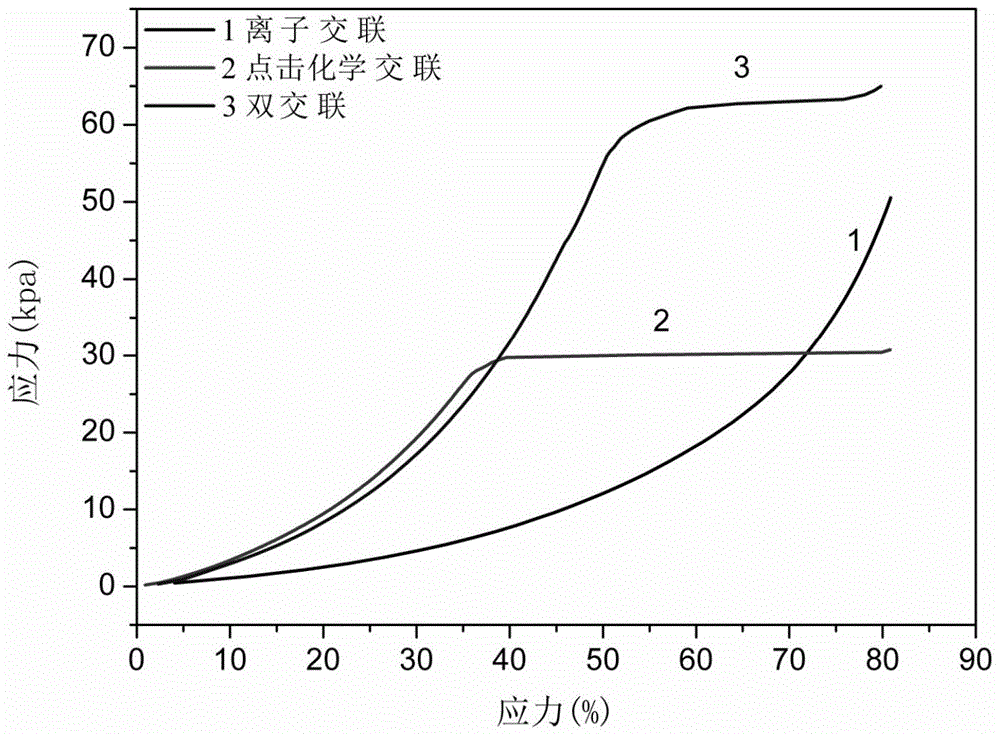

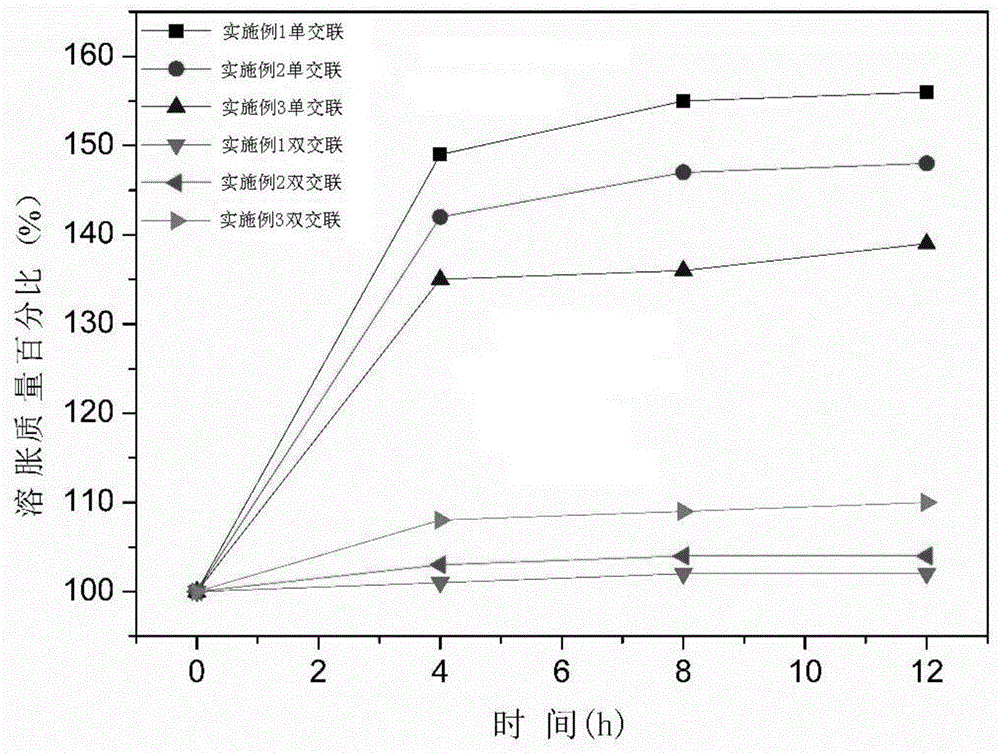

[0031] (1) Dissolve 0.5g of sodium alginate in 100mL of deionized water, add 0.495g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , then added 343 μL of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a furan-modified sodium alginate solid.

[0032] (2) Dissolve 75 mg of modified sodium alginate in 5 mL of deionized water, stir for 2 h, and add 37 mg of bismaleimide-terminated polyvinyl alcohol with a molecular weight of 2000 (purchased from Suzhou Derivative Biotechnology Co., Ltd. , References: Biomacromolecules2011, 12, 824–830), stirred for 10 minutes to dissolve, ultrasonicated for 5 minutes and transferred to a cylindrical mold with a height of 5 mm and a diameter of 10 mm; then the mold was placed in a 40°C oven for 6 hours to obtain a transparent gel.

[0033] (3) The above-mentioned gel was...

Embodiment 2

[0035] (1) Dissolve 0.5g of sodium alginate in 100mL of deionized water, add 0.750g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , and then added 490 μL of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a furan-modified sodium alginate solid.

[0036] (2) Dissolve 75mg of modified sodium alginate in 5mL of deionized water, stir for 2 hours, add 50mg of bismaleimide terminal polyvinyl alcohol with a molecular weight of 2000 after it is completely dissolved, stir for 10 minutes to dissolve, and then ultrasonicate for 5 minutes Transfer to a cylindrical mold with a height of 5 mm and a diameter of 10 mm; then place the mold in an oven at 40° C. for 6 hours to obtain a transparent gel.

[0037] (3) The above-mentioned gel was soaked in 10 ml of 100 mmol / L calcium chloride solution, and placed in a sha...

Embodiment 3

[0041] (1) Dissolve 0.5g of sodium alginate in 100mL of deionized water, add 1.125g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , and then added 735 μL of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a furan-modified sodium alginate solid.

[0042] (2) Dissolve 75mg of modified sodium alginate in 5mL of deionized water, stir for 2 hours, add 75mg of bismaleimide terminal polyvinyl alcohol with a molecular weight of 2000 after it is completely dissolved, stir for 10 minutes to dissolve, and then ultrasonicate for 5 minutes Transfer to a cylindrical mold with a height of 5 mm and a diameter of 10 mm; then place the mold in an oven at 40° C. for 6 hours to obtain a transparent gel.

[0043] (3) The above-mentioned gel was soaked in 10 ml of 100 mmol / L calcium chloride solution, and placed in a sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com