Antibacterial gel covalently grafted antibacterial polypeptide and preparation method thereof

A technology of antibacterial polypeptide and covalent grafting, applied in bandages, absorbent pads, medical science, etc., can solve the problems of loss of antibacterial ability, high localization, drug burst release, etc., and achieve good antibacterial ability, high selectivity, and responsiveness The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

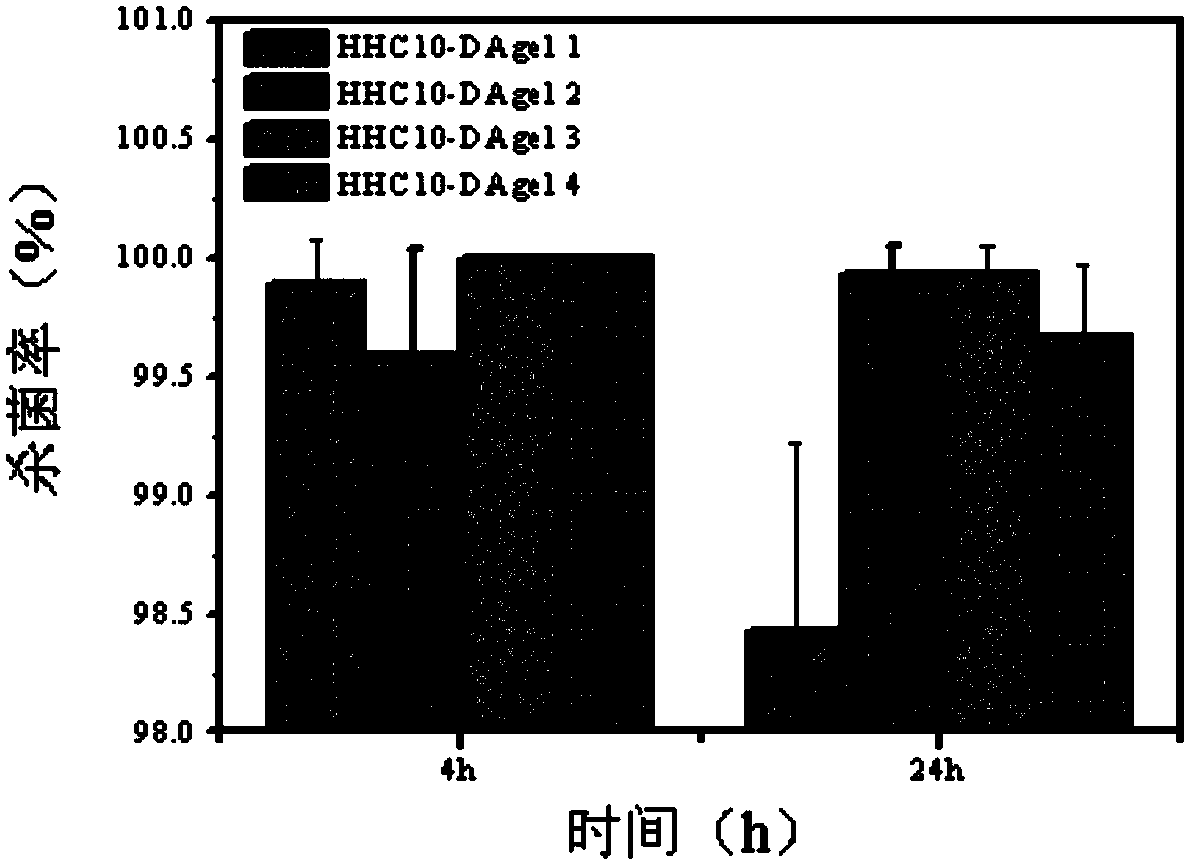

Embodiment 1

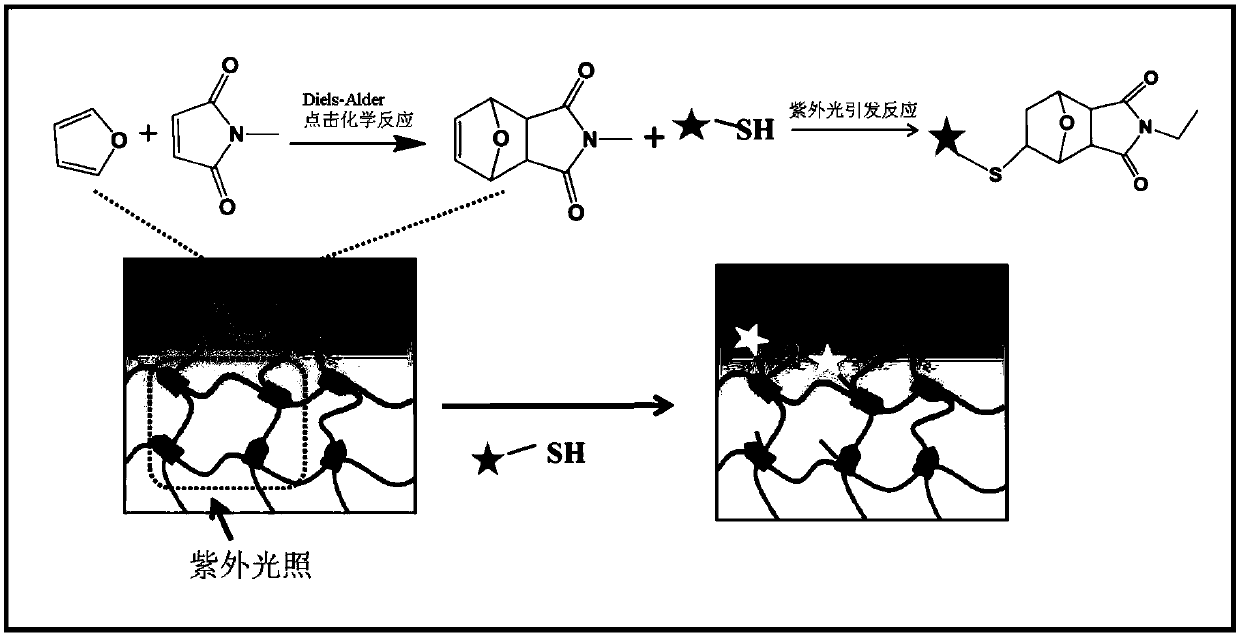

[0031] (1) Dissolve 0.5g of sodium alginate in 100ml of deionized water, add 0.750g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , then added 490 μl of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a solid modified sodium alginate.

[0032] (2) Dissolve 75mg of modified sodium alginate in 5ml of deionized water, stir for 2 hours, add 50mg of bismaleimide-terminated polyvinyl alcohol with a molecular weight of 2000 after it is completely dissolved, stir for 10 minutes to dissolve, and then ultrasonicate for 5 minutes Transfer to a cylindrical mold with a height of 5mm and a diameter of 10mm, and react and cross-link at a temperature of 37°C to obtain a gel.

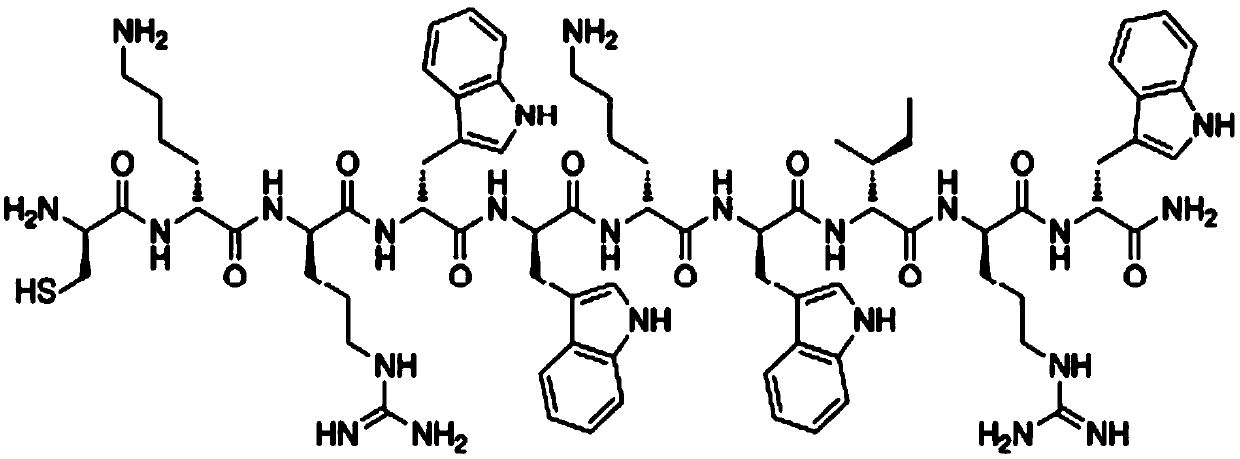

[0033] (3) Soak the above-mentioned gel in 1ml of CYS-HHC-10 antibacterial polypeptide solution with a concentration of 1mg / mL to fully swel...

Embodiment 2

[0035] (1) Dissolve 0.5g of sodium alginate in 100ml of deionized water, add 0.750g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , then added 490 μl of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a solid modified sodium alginate.

[0036] (2) Dissolve 75mg of modified sodium alginate in 5ml of deionized water, stir for 2 hours, add 50mg of bismaleimide-terminated polyvinyl alcohol with a molecular weight of 2000 after it is completely dissolved, stir for 10 minutes to dissolve, and then ultrasonicate for 5 minutes Transfer to a cylindrical mold with a height of 5mm and a diameter of 10mm, and react and cross-link at a temperature of 37°C to obtain a gel.

[0037] (3) Soak the above gel in 1ml of CYS-HHC-10 antibacterial polypeptide solution with a concentration of 2mg / mL, and fully swell. Then...

Embodiment 3

[0039] (1) Dissolve 0.5g of sodium alginate in 100ml of deionized water, add 0.750g of 4-(4,6-dimethoxytriazin-2-yl)-4-methylmorpholine hydrochloride, and stir for 0.5h , then added 490 μl of furfurylamine dropwise, and reacted in the dark for 24 hours. Dialysis was performed for 5 days using a dialysis bag with a molecular weight cut-off of 3500. Freeze-dry at -80°C to obtain a solid modified sodium alginate.

[0040] (2) Dissolve 75mg of modified sodium alginate in 5ml of deionized water, stir for 2 hours, add 50mg of bismaleimide-terminated polyvinyl alcohol with a molecular weight of 2000 after it is completely dissolved, stir for 10 minutes to dissolve, and then ultrasonicate for 5 minutes Transfer to a cylindrical mold with a height of 5mm and a diameter of 10mm, and react and cross-link at a temperature of 37°C to obtain a gel.

[0041] (3) Soak the above-mentioned gel in 1 ml of CYS-HHC-10 antibacterial polypeptide solution with a concentration of 3 mg / mL, and fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com