Crucible for melting crystalline silicon, method for producing crucible and spray coating liquid

A technology of crystalline silicon and spraying liquid, applied in the field of spraying liquid, can solve the problems of mechanical instability, unfavorable production and use, falling off or peeling, etc., and achieves the effect of solving difficult peeling and damage, difficult peeling and damage, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

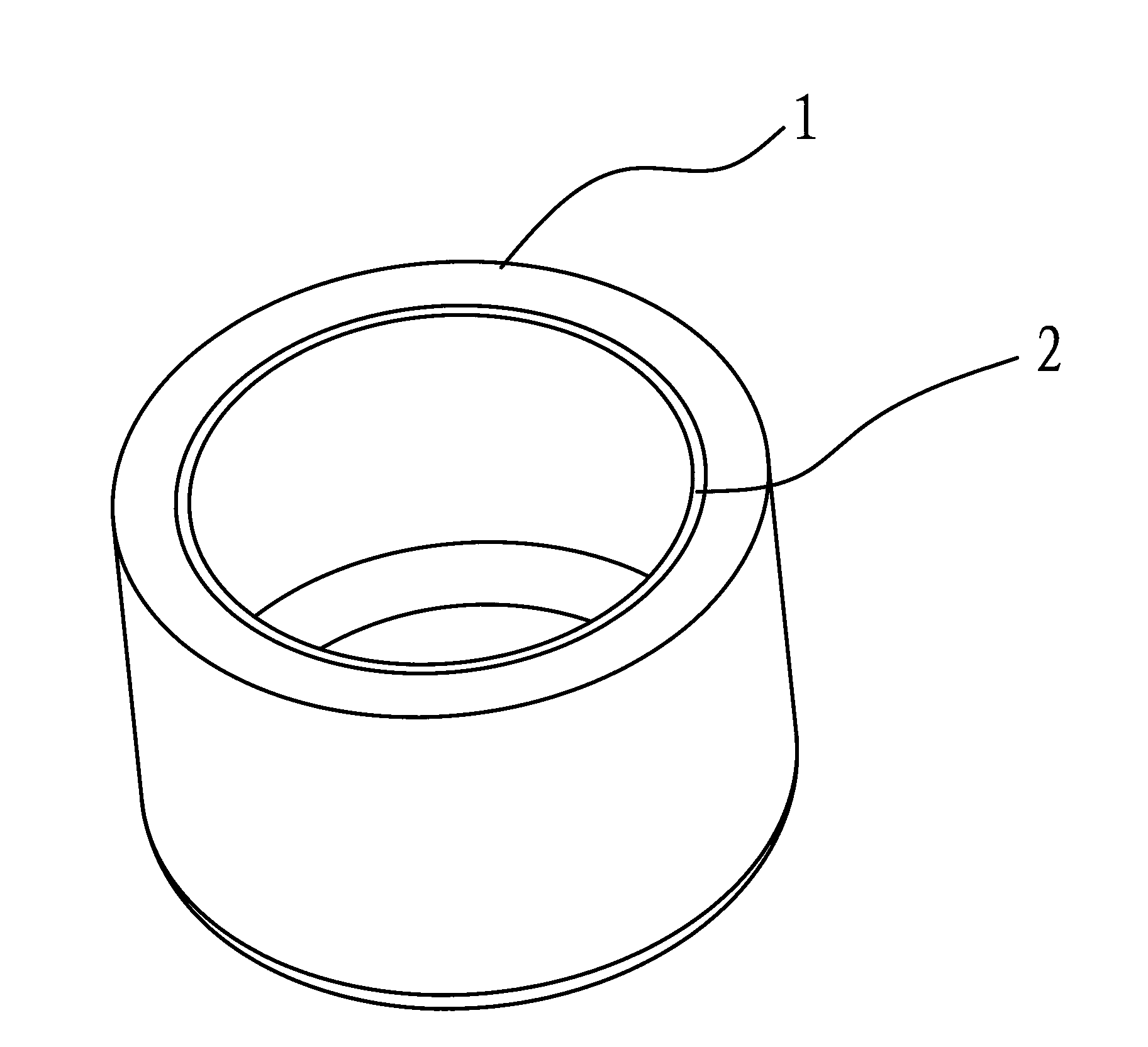

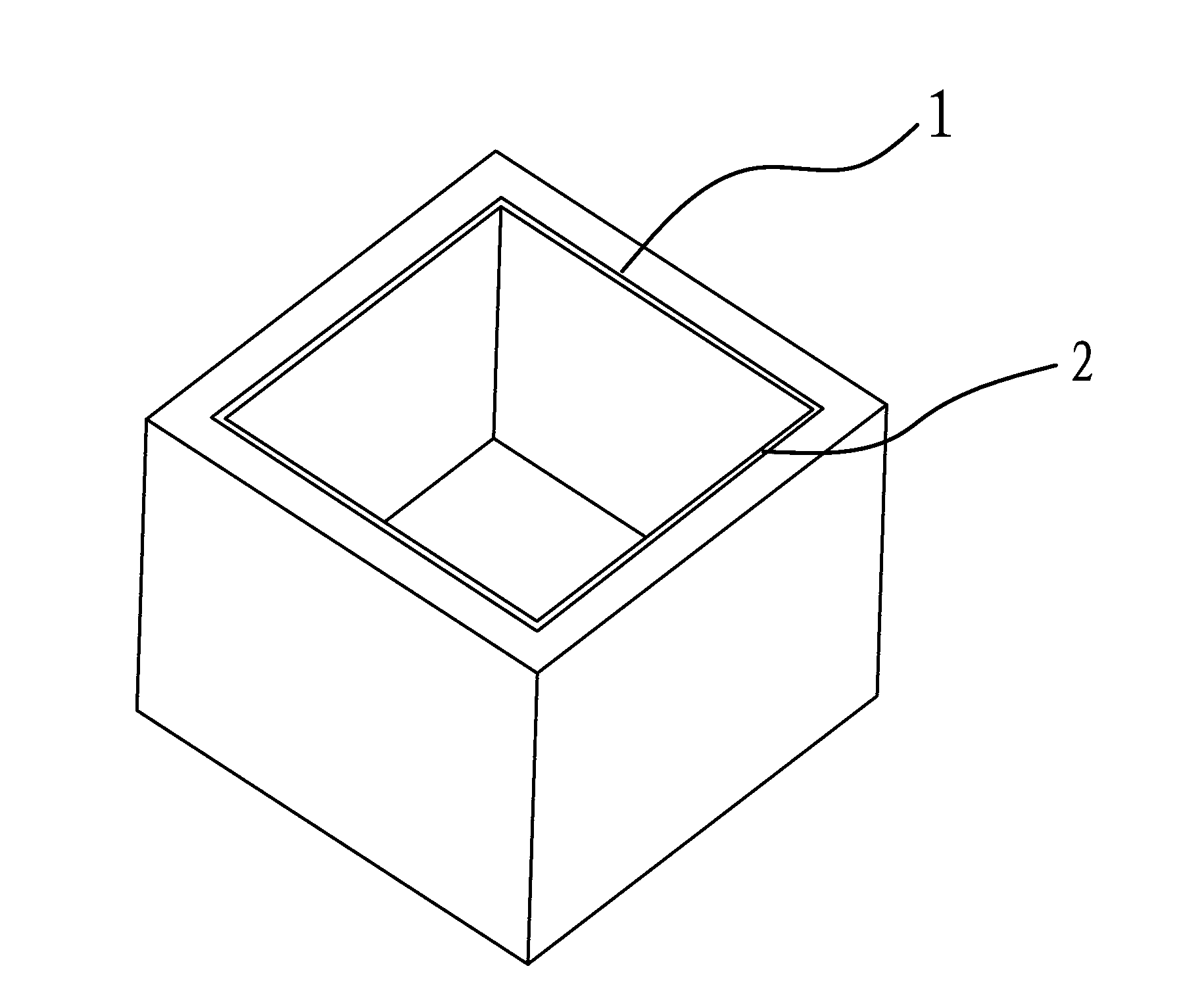

[0084] A method for preparing a crucible for melting crystalline silicon, the specific method is as follows:

[0085] Use alumina with a purity of 99.8% as raw material to sinter the main body of an alumina ceramic crucible with a capacity of 3000mL, and its shape is suitable for the requirements of equipment for melting crystalline silicon;

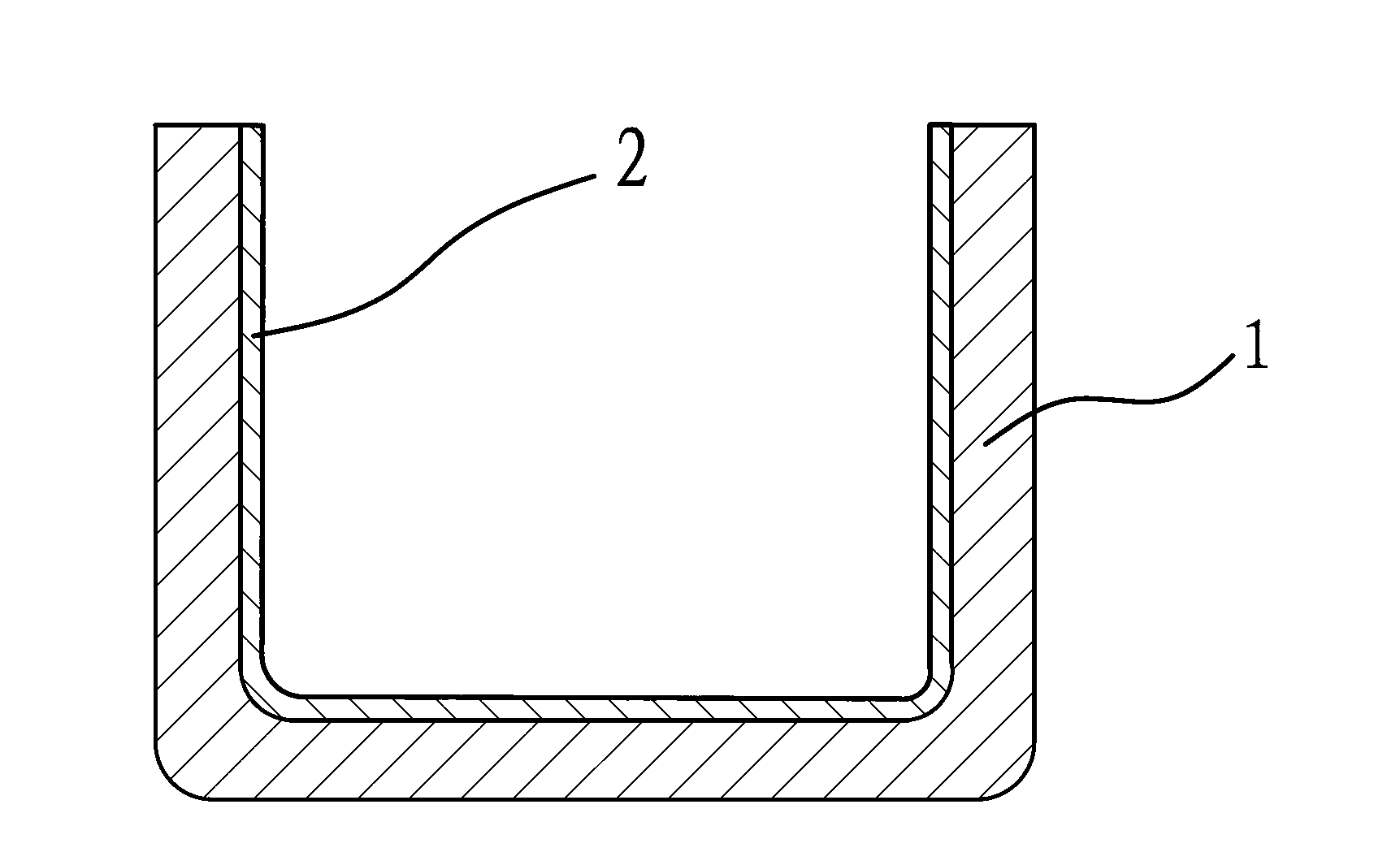

[0086] Then, use the spraying solution No. 1 in the above Table 1 to evenly spray on the inner surface of the above-mentioned alumina ceramic crucible body, heat up in the air with infrared heating at a heating rate of 0.5°C / min, raise the temperature to 120°C and maintain the temperature Carry out drying treatment for 1 hour, repeat above-mentioned spraying and drying treatment 1 time, obtain the crucible containing spraying liquid embryo film;

[0087] Put the crucible containing the sprayed liquid embryo film into a heating furnace, heat up to 400° C. in an oxidative gas environment (air environment), and keep it for 3 hours to burn o...

Embodiment 2

[0090] A method for preparing a crucible for melting crystalline silicon, the specific method is as follows:

[0091] Use alumina with a purity of 99.8% as raw material to sinter the main body of an alumina ceramic crucible with a capacity of 3000mL, and its shape is suitable for the requirements of equipment for melting crystalline silicon;

[0092] Grinding the inner surface of the above-mentioned alumina ceramic crucible body to increase the roughness of the inner surface of the crucible body;

[0093] Then, use the spraying liquid No. 3 in the above Table 1 to evenly spray on the inner surface of the above-mentioned polished crucible body, use infrared heating in the air to raise the temperature, the heating rate is 0.5°C / min, raise the temperature to 100°C and maintain the temperature Carry out drying treatment for 1 hour; repeat the above-mentioned spraying and drying treatment once to obtain a crucible containing the sprayed liquid embryo film;

[0094] Put the crucibl...

Embodiment 3

[0097] A method for preparing a crucible for melting crystalline silicon, the specific method is as follows:

[0098] Use alumina with a purity of 99.8% as raw material to sinter the main body of an alumina ceramic crucible with a capacity of 3000mL, and its shape is suitable for the requirements of equipment for melting crystalline silicon;

[0099] Grinding the inner surface of the above-mentioned alumina ceramic crucible body to increase the roughness of the inner surface of the crucible body;

[0100] Then, use the spraying liquid No. 5 in the above Table 1 to evenly spray on the inner surface of the above-mentioned polished crucible body, use infrared heating in the air to raise the temperature, the heating rate is 0.5 ° C / min, and the temperature is raised to 80 ° C and maintained at the temperature Carry out drying treatment for 1.5 hours; repeat the above-mentioned spraying and drying treatment process once to obtain a crucible containing the sprayed liquid embryo fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com