Cross-linked polyacrylonitrile-based amidoxime fiber, method for preparing same and application of cross-linked polyacrylonitrile-based amidoxime fiber

A polyacrylonitrile-based amidoxime and polyacrylonitrile fiber technology, which is applied in the field of fiber materials, can solve the problems of dissolution loss, poor fiber recycling performance, etc., and achieves high anti-swelling performance, high hydrolysis resistance, and long cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

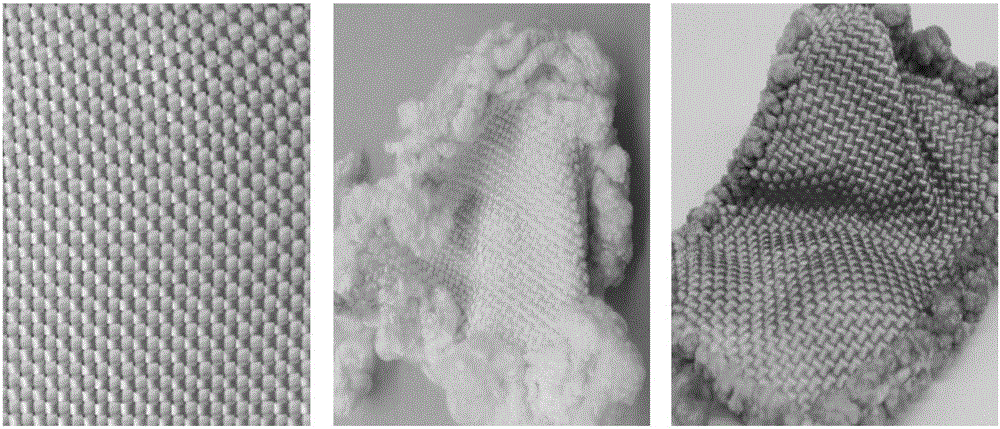

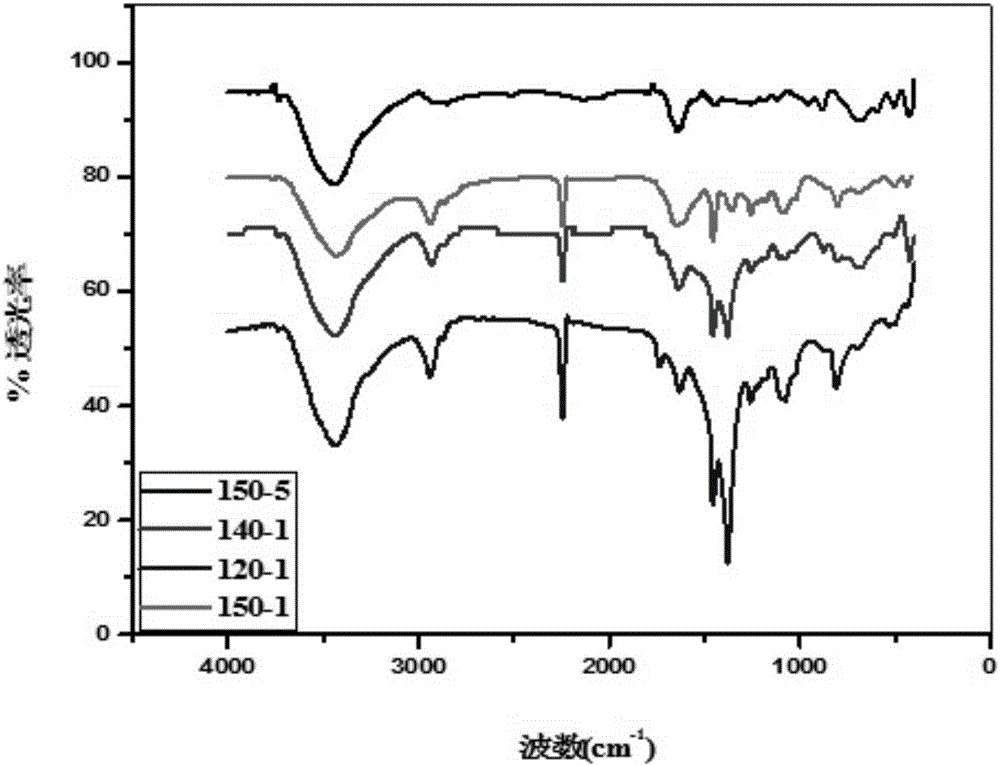

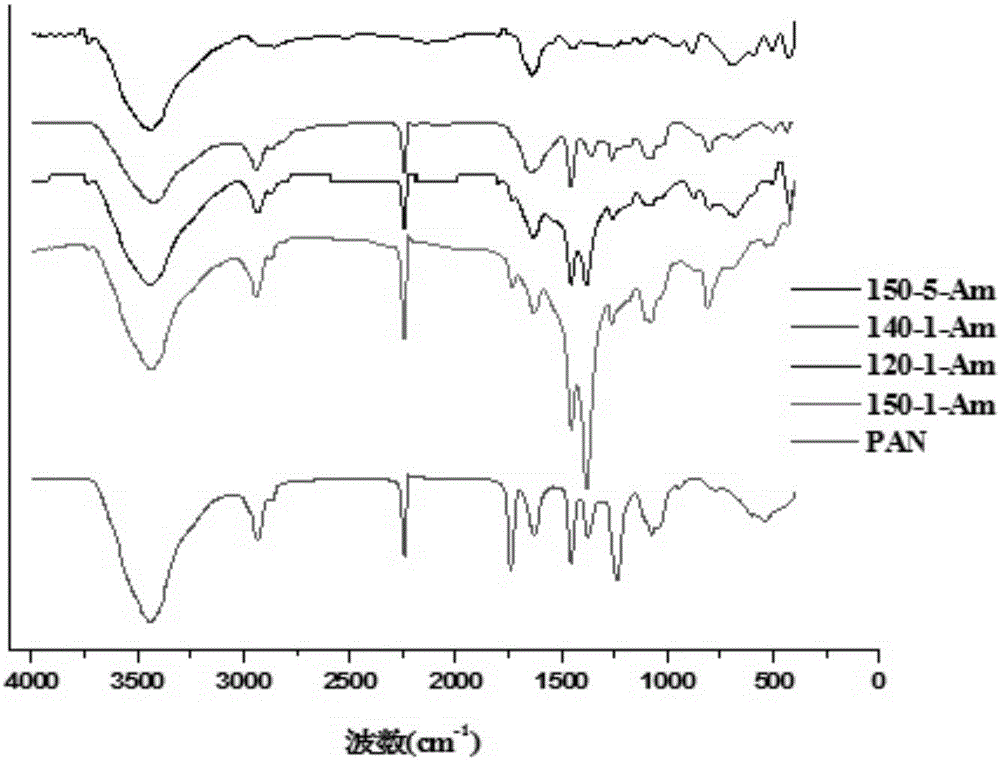

[0045] Embodiment 1 Preparation of cross-linked polyacrylonitrile amidoxime fiber of the present invention

[0046] (1) 2.12g polyacrylonitrile fiber (containing 0.04mol cyano group), 0.2mol triethylenetetramine, 0.2molH 2 O was reacted in a 100mL round-bottom flask at a reaction temperature of 120 °C for 1 h. After the reaction, the cross-linked fibers were washed and vacuum-dried at 60° C. to obtain cross-linked polyacrylonitrile fibers 120-1.

[0047] (2) According to the ratio of 1g polyacrylonitrile fiber raw material corresponding to 10g hydroxylamine hydrochloride and 5.5g sodium carbonate, get cross-linked polyacrylonitrile fiber 120-1 and hydroxylamine hydrochloride / sodium carbonate generation amidoximation reaction, adjust initial pH =7, T=70°C, the cross-linked polyacrylonitrile amidoxime fiber 120-1-Am was obtained.

Embodiment 2

[0048] Example 2 Preparation of cross-linked polyacrylonitrile amidoxime fiber of the present invention

[0049] According to the method of Example 1, the difference is that the reaction temperature in step (1) is 130° C., and the cross-linked polyacrylonitrile fiber 130-1 and the cross-linked polyacrylonitrile amidoxime fiber 130-1-Am are prepared.

Embodiment 3

[0050] Example 3 Preparation of cross-linked polyacrylonitrile amidoxime fiber of the present invention

[0051] According to the method of Example 1, the difference is that the reaction temperature in step (1) is 140° C. to prepare cross-linked polyacrylonitrile fiber 140-1 and cross-linked polyacrylonitrile amidoxime fiber 140-1-Am.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com