Solvent-resistant polymer nanofiltration membrane as well as preparation method and application thereof

A polymer and solvent-resistant technology, applied in the field of membrane separation, can solve the problems of low membrane flux and high membrane flux, and achieve the effects of improving swelling resistance, improving mechanical strength, and good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

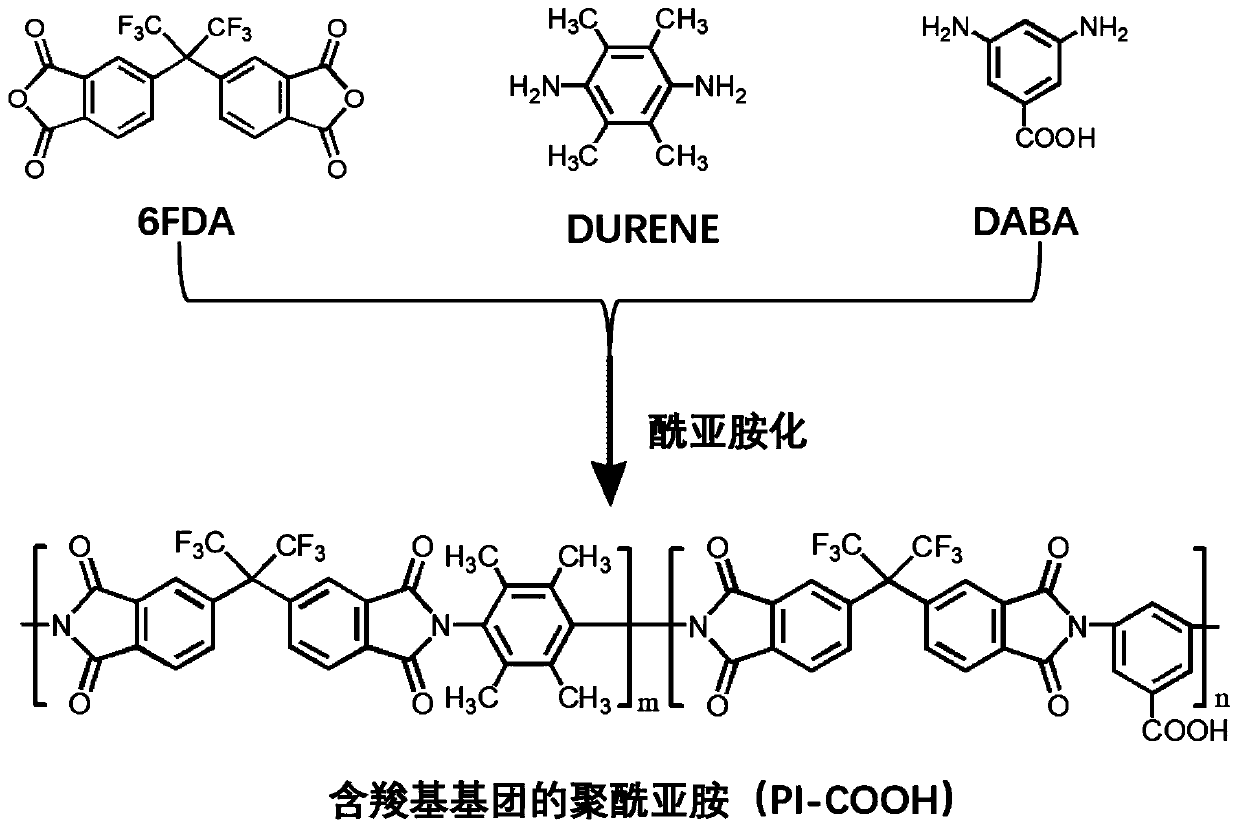

[0089] Add DURENE and DABA (total mole number is 1 mol) to 300 mL of m-cresol solution at room temperature, add 44.4 g of 6FDA in batches, stir for 24 hours to form a homogeneous solution, and then add 50 mL of anhydrous toluene. The temperature of the system was gradually raised to 200° C. and kept for 6 hours. Cool down, pour the product solution into methanol, and keep stirring. The obtained product was vacuum-dried at 120° C. for 12 hours to obtain a polyimide material.

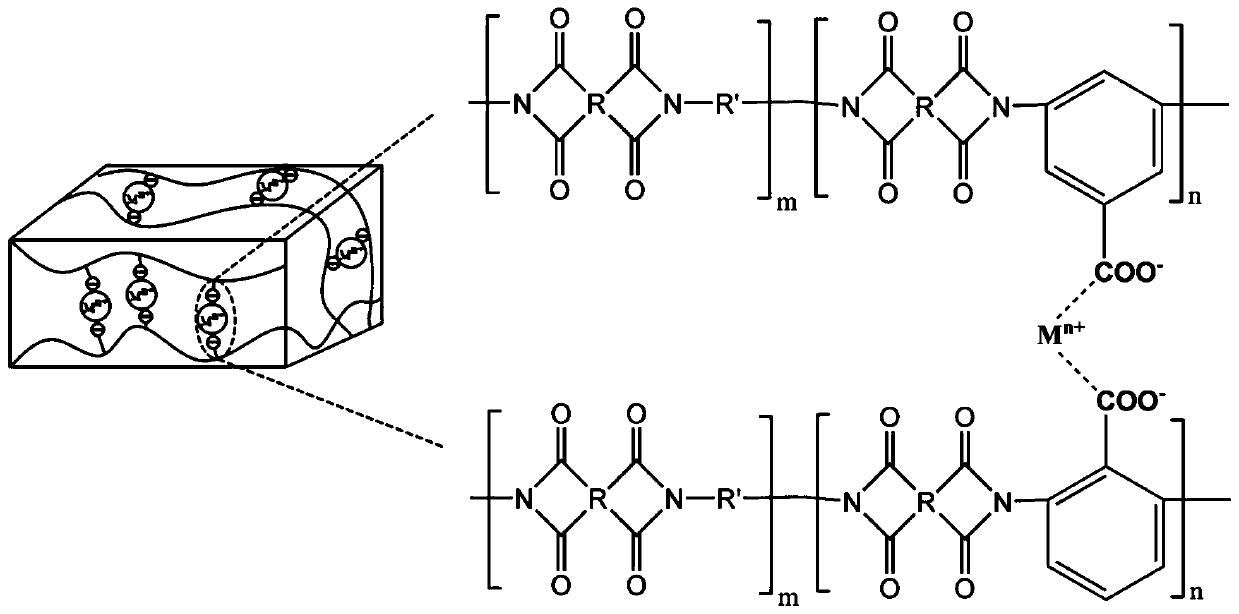

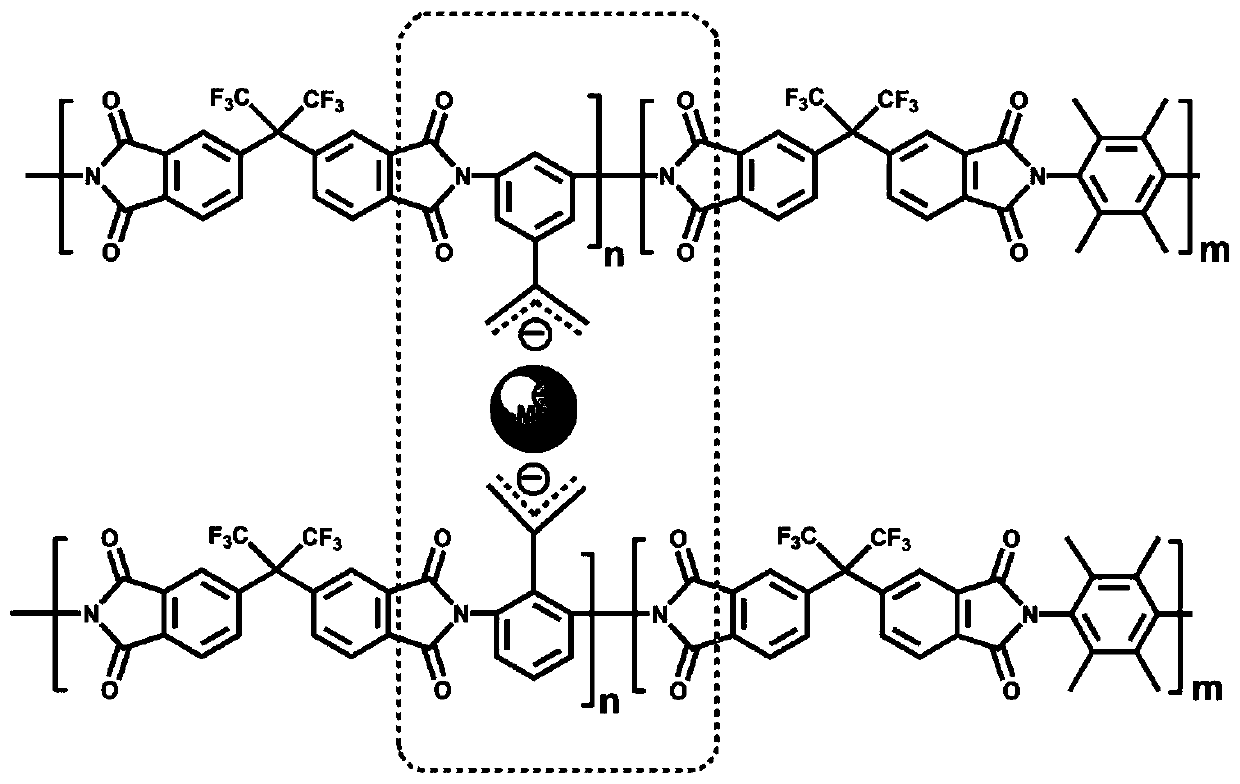

[0090] The chemical formula and synthetic route of the polyimide copolymer (PI-COOH) containing carboxyl group in the polyimide material that forms are as figure 2 As shown, wherein, m is an integer greater than or equal to 1, n is an integer greater than or equal to 1, and n / m=10-1000:1000-10.

[0091] Take the polyimide material and dissolve it in a mixed solvent of N,N-dimethylformamide and 1,4-dioxane (10:1-1:1), stir overnight, and leave it for 24 hours to obtain 10 - 40 wt% film-forming solution...

Embodiment 1

[0098] Add DURENE (0.09mol, 14.8g) and DABA (0.01mol, 1.5g) to 300mL m-cresol solution at room temperature, add 44.4g (0.1mol) of 6FDA in batches, and stir for 24 hours until a uniform solution is formed, Then 50 mL of anhydrous toluene and catalyst quinoline were added to the mixture. The temperature of the system was gradually raised to 200° C. and kept for 6 hours. Cool down, pour the product solution into methanol, and keep stirring. The obtained product was vacuum-dried at 120°C for 12 hours to obtain the polyimide material PI-COOH 10 , the degree of polymerization (m+n) is above 300, m:n=9:1.

[0099] Take the polyimide material and dissolve it in a mixed solvent of N,N-dimethylformamide and 1,4-dioxane (3:1), stir overnight, and leave it for 24 hours to obtain a 22wt% film-forming solution.

[0100] Preparation of flat film material: adjust the height of the scraper to 300 μm, control the humidity at 30-40%, pour the film-forming solution on the glass plate for scra...

Embodiment 2

[0104] The synthesis method of the polyimide material is the same as in Example 1, except that the amount of DURENE is 0.08mol (13.1g), and the amount of DABA is 0.02mol (3.0g), to obtain the polyimide material PI-COOH 20 , the degree of polymerization (m+n) is above 300, m:n=4:1.

[0105] The preparation method of the solvent-resistant polymer nanofiltration membrane is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com