Photodegradable and biodegradable polyethylene plastic bag

A polyethylene plastic bag, biodegradation technology, applied in the field of plastics, can solve the problems of insignificant degradation effect, reduce the use of garbage bags, and the effect is not too obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A photodegradable and biodegradable polyethylene plastic bag has the following components:

[0019] 100 parts of LDPE, 5 parts of filler, 0.1 part of compatibilizer, 0.1 part of photosensitizer, 1-10 parts of corn starch, 1 part of microcrystalline cellulose, 2 parts of silane coupling agent.

[0020] The filler is CaCO 3 ; The compatibilizer is OPE-4; the photosensitizer is FeST3; the silane coupling agent is KH570.

[0021] The preparation process is as follows:

[0022] (1), cornstarch, calcium carbonate powder, microcrystalline cellulose are pulverized into superfine particles;

[0023] (2), dry cornstarch, add silane coupling agent to carry out surface treatment, add compatibilizer, set aside;

[0024] (3), calcium carbonate grinding adds activator, dispersant, for subsequent use;

[0025] (4), mixing the materials obtained in steps (2), (3), adding LDPE, microcrystalline cellulose, photosensitizer, two-roll mixing, crushing, extruding and granulating, to obtai...

Embodiment 2

[0028] A photodegradable and biodegradable polyethylene plastic bag has the following components:

[0029] 100 parts of LDPE, 8 parts of filler, 0.5 parts of compatibilizer, 0.3 parts of photosensitizer, 8 parts of corn starch, 6 parts of microcrystalline cellulose, and 5 parts of silane coupling agent.

[0030] The preparation process is the same as in Example 1.

Embodiment 3

[0032] A photodegradable and biodegradable polyethylene plastic bag has the following components:

[0033] 100 parts of LDPE, 10 parts of filler, 1.5 parts of compatibilizer, 1 part of photosensitizer, 10 parts of corn starch, 10 parts of microcrystalline cellulose, 11 parts of silane coupling agent.

[0034] The filler is CaCO 3 ; The compatibilizer is OPE-4; the photosensitizer is FeST3; the silane coupling agent is KH570.

[0035] The preparation process is the same as in Example 1.

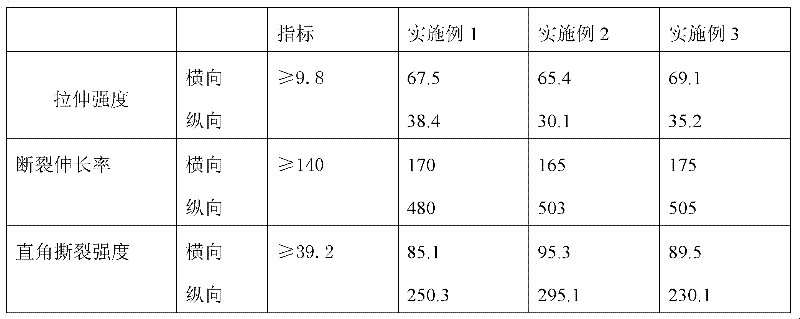

[0036] The mechanical property parameters of the light and biodegradable plastic prepared in the embodiment of the present invention are shown in Table 1, wherein the unit of tensile strength is MPa, the unit of elongation at break is %, and the unit of right-angle tear strength is kN / m.

[0037] Table 1

[0038]

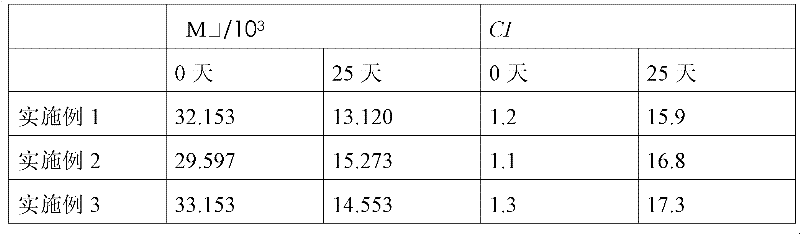

[0039] Table 2 shows the parameter changes of the photodegradable and biodegradable plastics prepared in the examples of the present invention under natural exposure.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com