Controllable-shape long-carbon-chain polyamide powder base and controllable-shape high-conductivity composite powder material

A technology of carbon chain polyamide and composite powder, which is applied in the field of polymers, can solve problems such as static charge accumulation, and achieve the effects of low cost, controllable shape, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1) Dissolution of PA1012: Weigh 1g of PA1012 resin with a melt index of 1g / 10min, measure 100ml of DMSO, mix and heat to 150°C at a stirring speed of 300rpm, and keep warm for 2 hours to obtain a light yellow DMSO solution of PA1012;

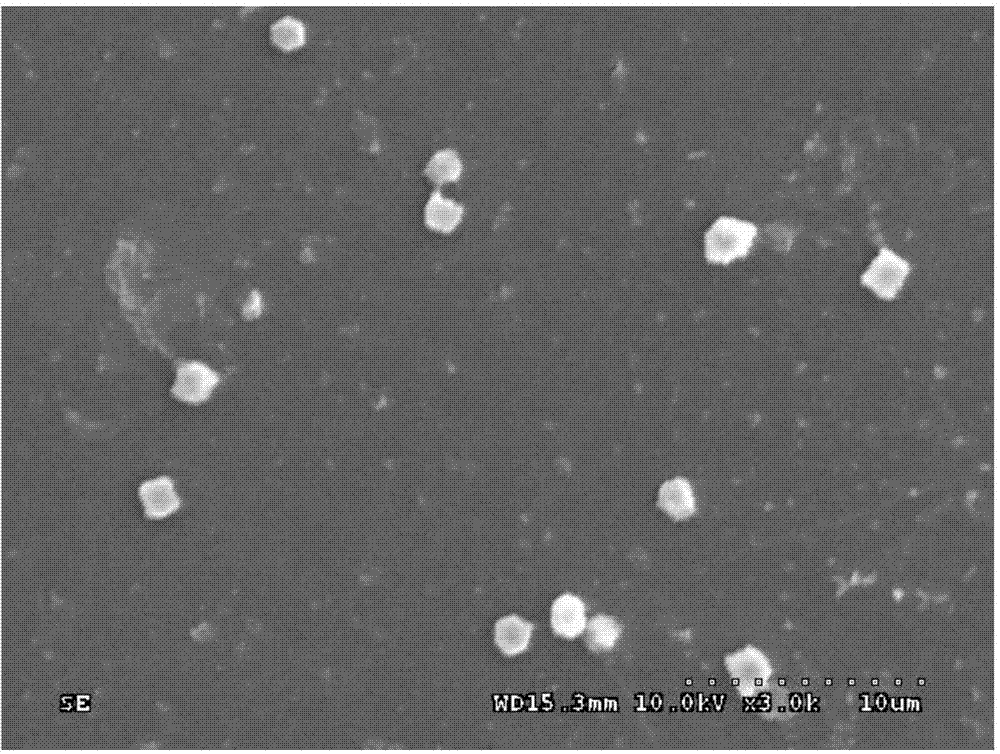

[0063] 2) Precipitation of PA1012 powder: Take 1L of 99% methanol, heat it to 60°C for 5 minutes, and use it as a precipitating agent; then add a magnet and stir vigorously at a speed of 1000rpm, and at the same time use a glass rod to drain the DMSO solution into 60°C methanol precipitation In the analysis agent; the precipitated suspended matter is collected and washed to obtain a nearly spherical long carbon chain polyamide powder matrix, and the average particle diameter of the powder matrix is 1 μm.

[0064] The obtained near-spherical long-carbon-chain polyamide powder matrix can be further reacted with polyaniline to prepare a near-spherical long-carbon-chain polyamide / polyaniline composite powder material through in-situ polymeri...

Embodiment 2

[0067] 1) Dissolution of PA1012: Weigh 1g of PA1012 resin with a melt index of 4g / 10min, measure 100ml of DMSO, mix and heat to 150°C at a stirring speed of 800rpm, and keep warm for 2 hours to obtain a light yellow DMSO solution;

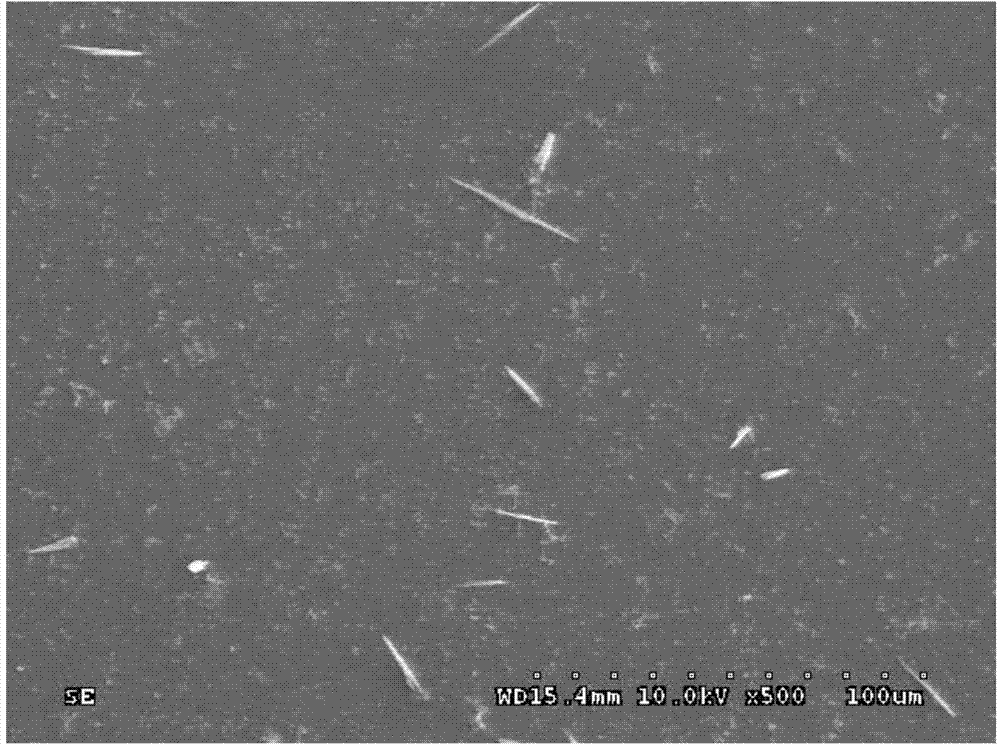

[0068] 2) Precipitation of PA1012 powder: Measure 1L of deionized water, heat it to 80°C and keep it for 5 minutes as a precipitating agent; then add magnets and stir vigorously at 1000rpm, and at the same time use a glass rod to drain DMSO solution into 80°C for deionization In the water precipitating agent: collect the precipitated suspended matter, wash to obtain the needle-shaped long carbon chain polyamide powder matrix, the average size of the long axis of the powder matrix is 10 μm, and the average aspect ratio is 12.

[0069] The needle-shaped long-carbon-chain polyamide / polyaniline composite powder material can be prepared by in-situ polymerization reaction of the obtained needle-shaped long-carbon-chain polyamide powder matrix and polyan...

Embodiment 3

[0072] 1) Dissolution of PA1012: Weigh 1g of PA1012 resin with a melt index of 3g / 10min, measure 100ml of DMSO, 5g of PVP, mix and heat to 150°C at a stirring speed of 500rpm, and keep it warm for 2 hours to obtain a light yellow DMSO solution;

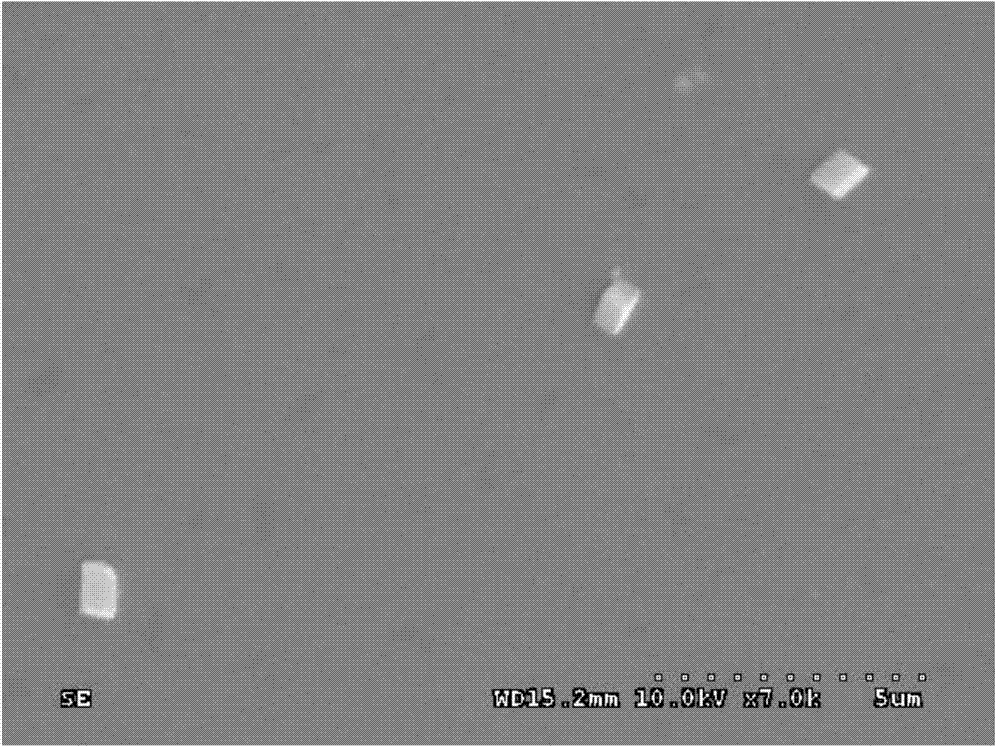

[0073] 2) Precipitation of PA1012 powder: Measure 1L of 99% ethanol, weigh 10g of PVP, mix and put it in an ice-water bath at 0°C for 30 minutes as a precipitating agent; then add magnets and stir vigorously at 1000rpm, while using a glass rod Drain the DMSO solution into the ethanol precipitant; collect the precipitated suspended matter, wash to obtain a rhombohedral long carbon chain polyamide powder matrix, and the average particle size of the powder matrix is 8 μm.

[0074] The obtained orthorhombic long carbon chain polyamide powder matrix can be further reacted with polyaniline through in-situ polymerization to prepare a rhombohedral long carbon chain polyamide / polyaniline composite powder material.

[0075] The in-situ polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com