Method for constructing composite foundation of piles and ground interactive slurry bonded dispersed body material

A technology of bulk material piles and composite foundations, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve problems affecting the quality of foundation reinforcement, affecting the ecological environment, and occupying cultivated land, so as to reduce foundation settlement, protect the environment, The effect of improving the bearing capacity of the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

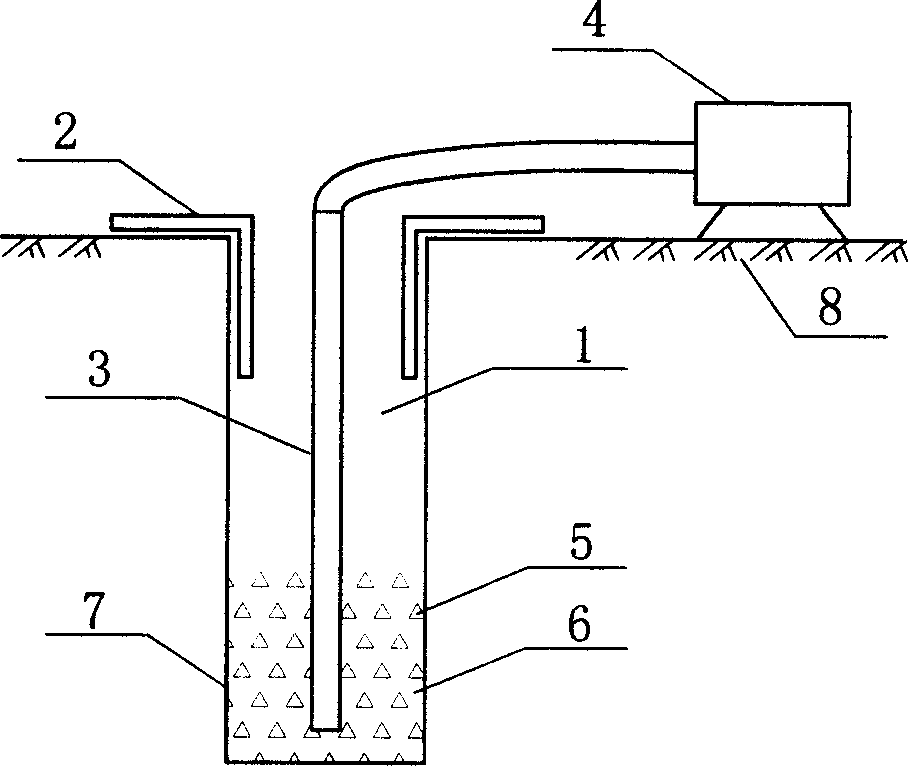

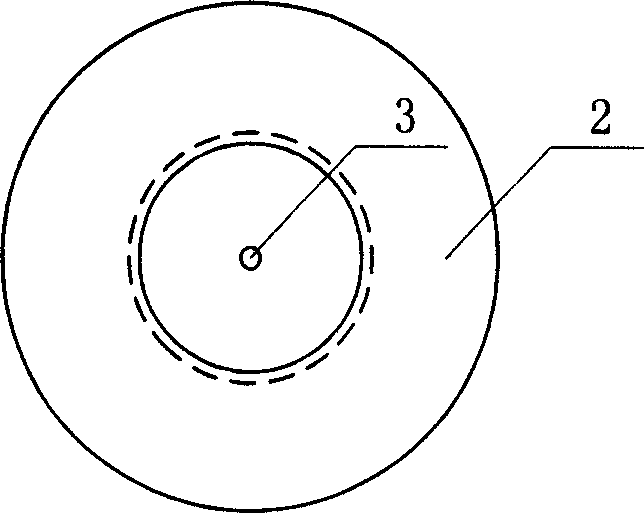

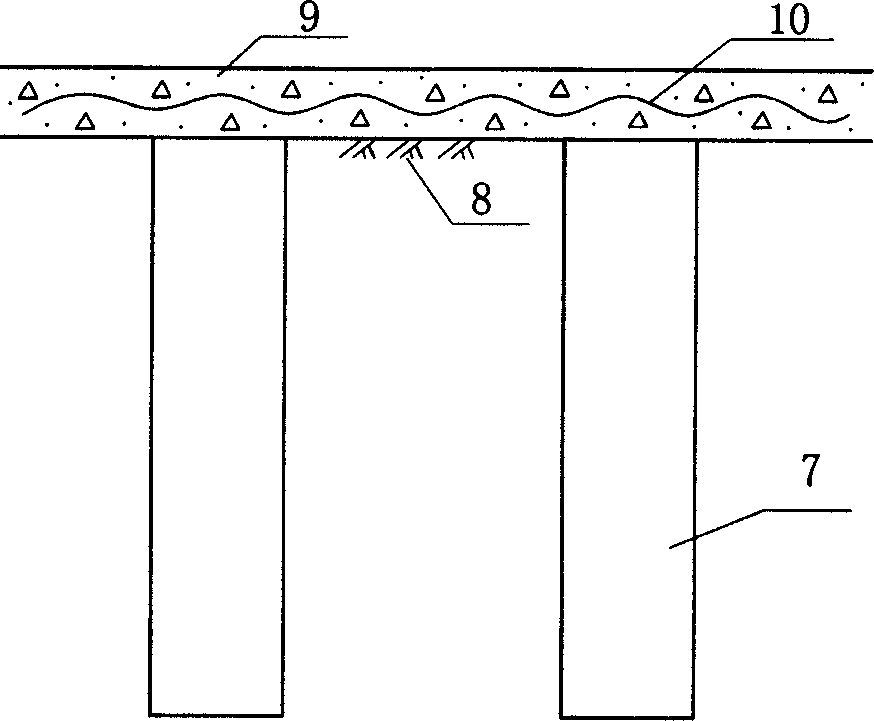

[0010] Such as figure 1 , 2 As shown in 3 and 3, a new construction method of pile-solid-solid-dispersed-material-pile composite foundation with interaction between pile and soil, its construction steps:

[0011] (1) Hole forming. The hole forming process of the grouted pile is basically the same as that of the general bored pile. Generally, a drilling rig is used to form a hole, and the natural pulping wall is used. When the hole wall is not easy to maintain, the artificial pulping wall is used. In engineering applications, bentonite and alkali are used to artificially make slurry to protect the wall, and the specific gravity of the slurry is controlled within a certain range.

[0012] (2) Throw stones to wash the holes. After the drilling is completed, wash the holes twice. The first hole washing is carried out after the drilling is completed and before the aggregate is put in. The second hole washing is carried out during the process of putting in the aggregate, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com