Steam-gas displacement and gravity oil drain composite exploiting method

A technology of gravity drainage and production method, which is applied in well completion and oil recovery technology, oil field drilling, and can solve problems such as insufficient steam generator injection capacity and insufficient water resources at sea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

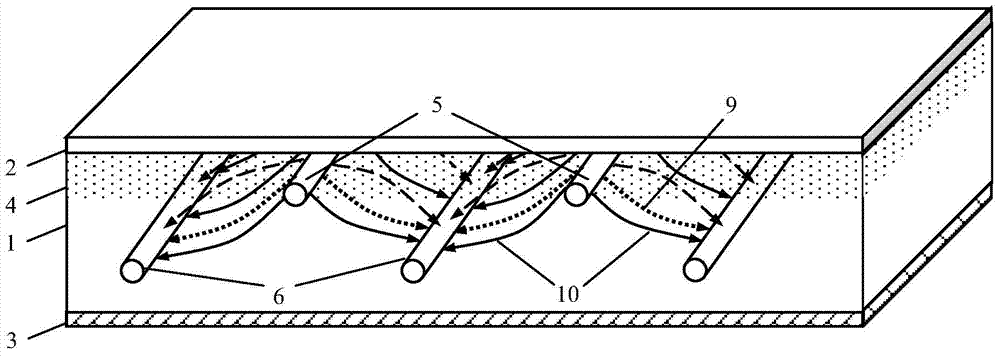

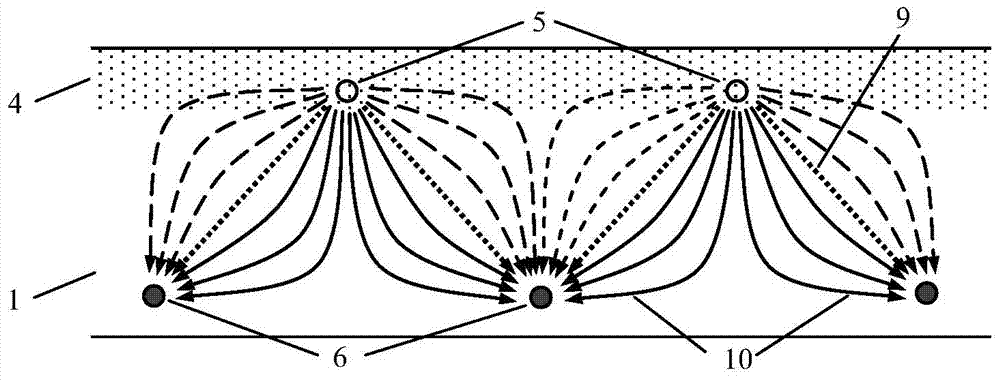

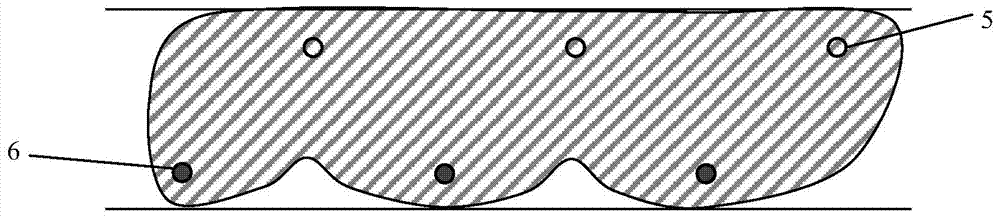

[0086] refer to figure 1 and figure 2 , in this example, steam-N 2 The combined recovery method of displacement and gravity drainage can exploit horizontal, homogeneous and thick heavy oil reservoirs.

[0087] A 750m×500m×30m horizontal, homogeneous, thick heavy oil reservoir 1a, the top of the reservoir is the overburden 2, the bottom is the underburden 3, the top depth of the reservoir is 1000m, and the thickness is 30m. The specific reservoir The parameters are shown in Table 1. A homogeneous reservoir geological model with 15 × 100 × 15 grids is established. The size of the grid in the X direction is 50 m, the size of the grid in the Y direction is 5 m, and the size of the grid in the Z direction is 2 m. Steam-N 2 The reservoir model of displacement and gravity drainage combined recovery is as follows: image 3 As shown, the three injection wells 5 and the three production wells 6 are all horizontal wells, the horizontal section (that is, the horizontal completion se...

Embodiment 12

[0116] A Steam-N 2 The combined recovery method of displacement and gravity drainage is the same as in Example 1.1, except that the thickness of the reservoir is 50m, the injection well 5 is arranged 25m below the top of the reservoir, the production well 6 is arranged 5m above the bottom of the reservoir, and the injection well The vertical distance between the injection well and the production well is 20m, the horizontal distance between the injection well and the production well is 50m, and the horizontal section length of the injection well and the production well is 500m.

Embodiment 13

[0118] A Steam-N 2 The combined recovery method of displacement and gravity drainage is the same as in Example 1.1, except that the reservoir depth is 220m, the original reservoir pressure is 2MPa, the crude oil viscosity is 235 centipoise, the injection well 5 is arranged 5m below the top of the reservoir, and the production well 6 is arranged 5m above the bottom of the reservoir, the vertical distance between the injection well and the production well is 20m, the horizontal distance between the injection well and the production well is 70m, and the length of the horizontal section of the injection well and the production well is 300m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com