Ag-Fe3O4 magnetic nano catalyst and its application in phenylethene epoxidation

A nano-catalyst, 1.ag-fe3o4 technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry and other directions, can solve the problems of small particle size of nano-catalysts and achieve solvent The effect of low pollution, convenient separation, excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

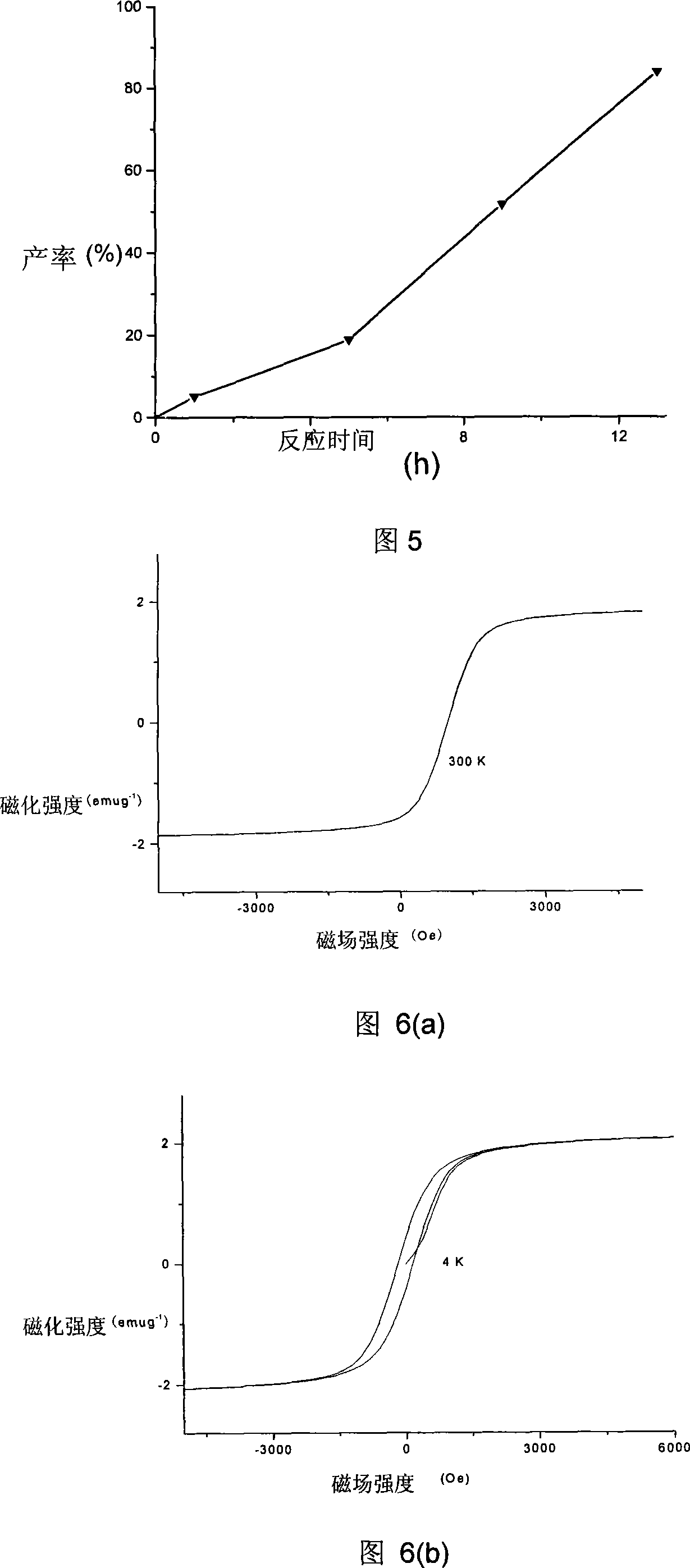

[0027] Preparation of Ag-Fe 3 o 4 Composite magnetic nanocatalyst: 2.975 mmol FeCl 3 ·6H 2 O, 8.925mmol PVP (K30 molecular weight: 10000), 29.75mmol CH 3 COONa, 2.975mmol AgNO 3 Sequentially added to 35mL of ethylene glycol, the resulting solution was stirred in the dark until a uniform suspension was formed, and then the suspension was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner capacity of 50ml. React at 180°C for 1 hour, then react at 200°C for 8 hours, then cool naturally to room temperature; the obtained brown-black product is sedimented and separated under the action of a magnet, and redispersed in absolute ethanol for cleaning. This cycle is repeated 3 times, and some ions on the surface , excess polymer and other impurities are washed off; the resulting solid is vacuum-dried at room temperature to finally obtain 0.555 grams of solid powder, namely Ag-Fe 3 o 4 Composite magnetic nanocatalysts.

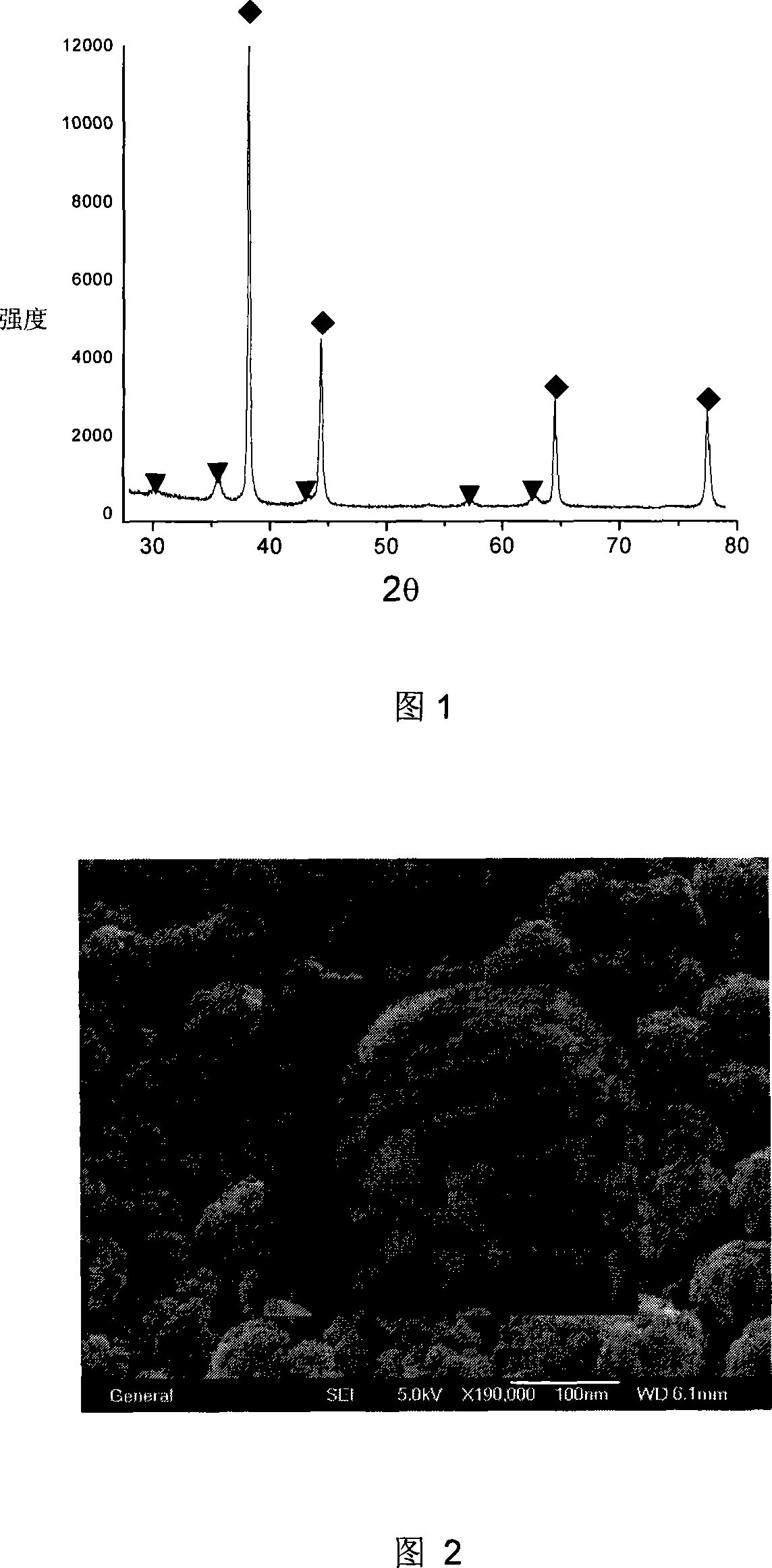

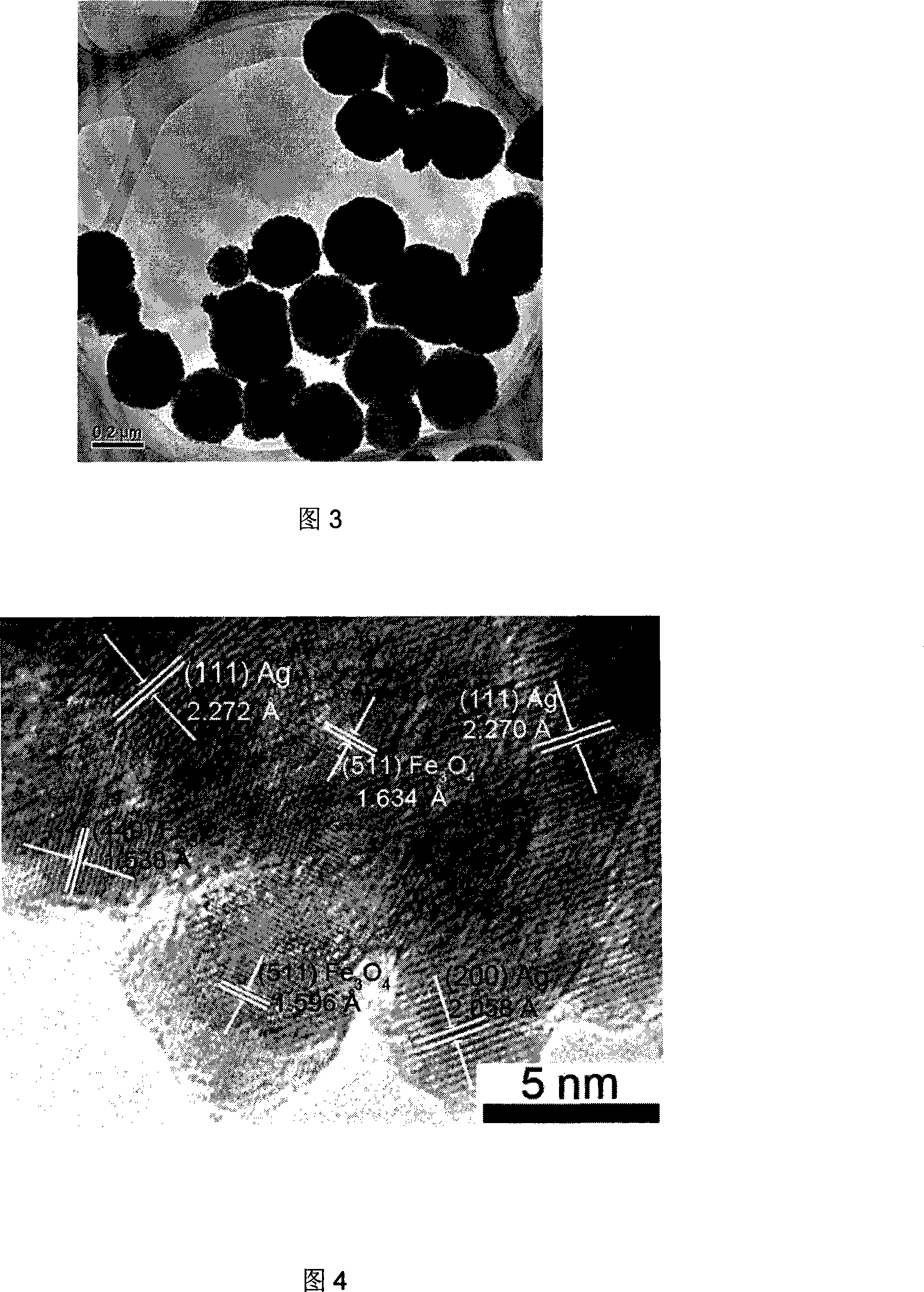

[0028] Figure 1 is the obt...

Embodiment 2

[0033] Similar to the steps in Example 1, react at 185°C for 1 hour and 200°C for 8 hours to obtain Ag-Fe 3 o 4 The composite magnetic nano-catalyst particles have an average particle diameter of 225nm.

Embodiment 3

[0035] Similar to the steps in Example 1, react at 180°C for 1 hour and 210°C for 8 hours, and Ag-Fe is also obtained 3 o 4 The composite magnetic nano-catalyst particles have an average particle diameter of 306nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com