Heat insulation soft thin composite fabric, preparing method and its use

A composite fabric, thermal insulation technology, applied in the field of textile composite materials and technical textiles, can solve problems such as affecting movement and carrying, and being too heavy, and achieve the effects of convenient combination and forming, simple composition, and wide application fields.

Inactive Publication Date: 2005-03-02

DONGHUA UNIV

View PDF0 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Theoretically, it is suitable for both cold and hot environments, but it is too thick and affects movement and carrying

Method used

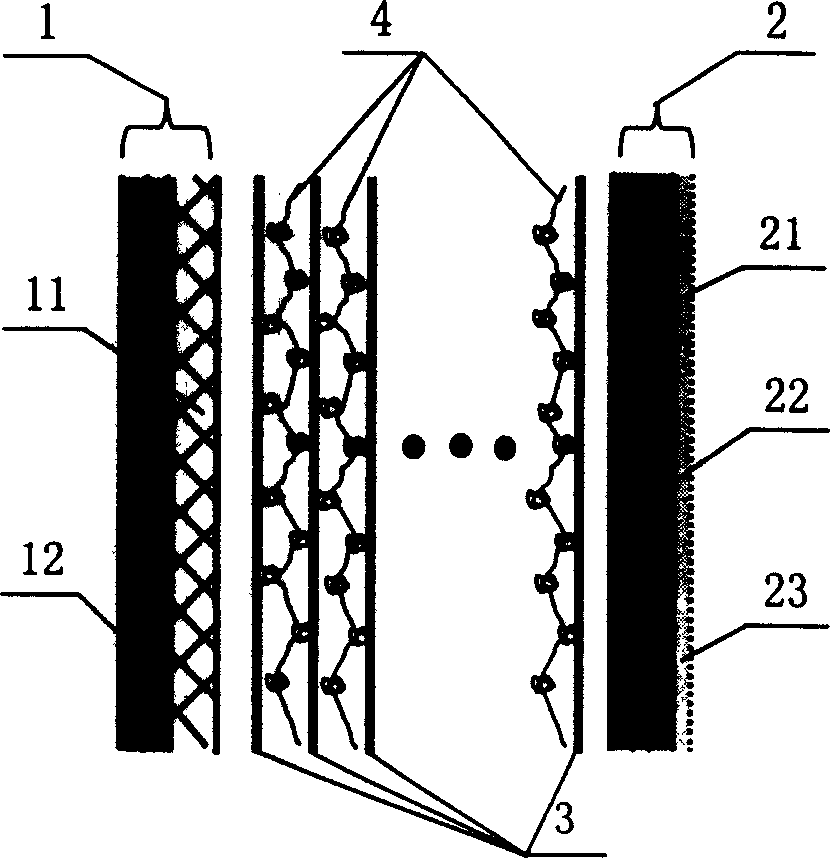

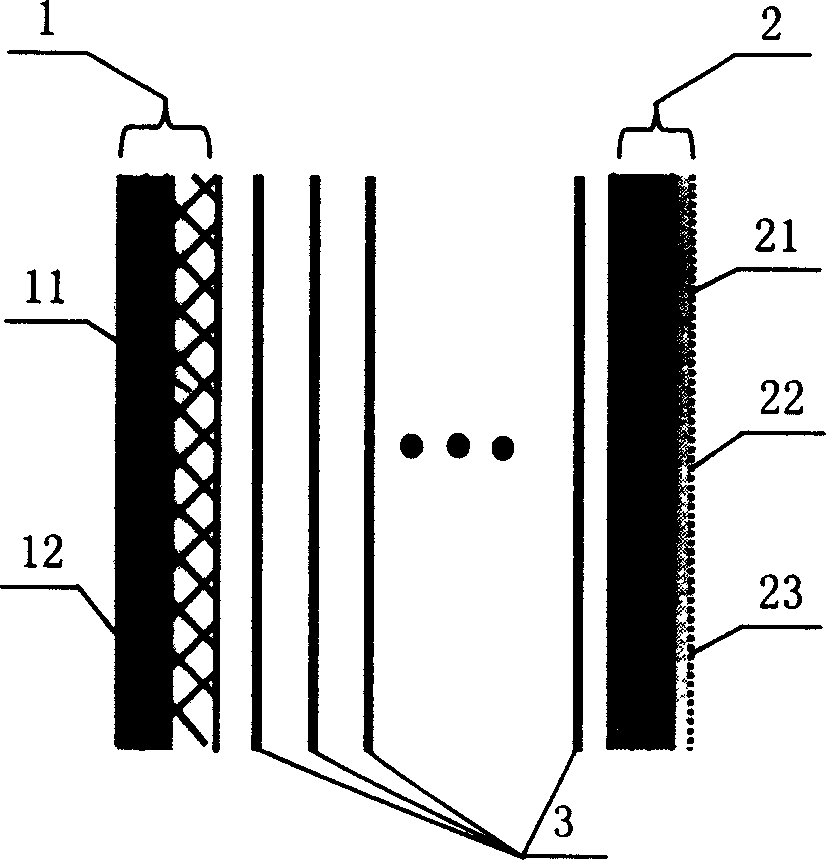

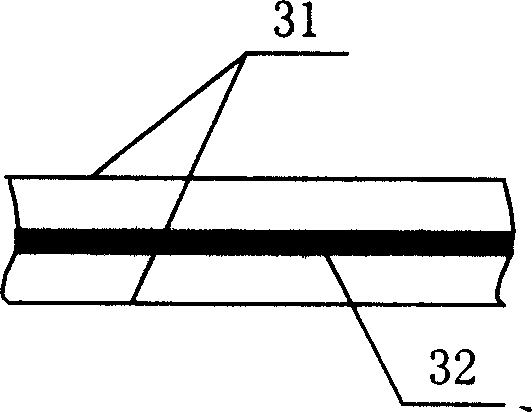

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0037] *The softness of the fabric when relatively constant

[0038] Δ Relative to the comparison of 8-layer samples

example 2

[0040] 16 layers of composite fabric

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to the composite fabric structure with one side capable of bearing high temperature, low temperature or composite effect of high temperature and low temperature, and the other side maintained at room temperature state of 5-35 deg.c. The fabric structure has heat and cold resisting high performance coated fabric in one side; soft, comfortable, antifrosting and condensation-preventing fabric in the other side; and composite fabric of heat insulating polymer and compounded metal film as the middle layer, which may have also net lining fabric with stable thickness and size. The composite fabric has natural thickness of 3-12 mm, practical densified thickness of 1-3 mm and unit area weight of 150-550 g / sq m, may be adhered and sawn, and is completely sealed suitable for use as heat insulating protecting material in the environment condition from -130 deg.c to 120 deg.c.

Description

Technical field: [0001] The invention belongs to the field of textile composite materials and technical textiles, and relates to the technology of light, thin and soft materials for heat insulation and protection of human body or environment temperature. Human body protection and environmental heat insulation in special occasions such as military affairs, geological exploration, ocean, aerospace, sports, rescue, etc. Background technique: [0002] Human body protection is the cause of research on protective materials. Soft protective materials are a necessary condition for humans to operate and move normally in special occasions when they explore the world and the universe. Most of the high-performance flexible protective material research and patent (KoTse-Hao. Fire-fighting appliance.USP 5153055,1992; Smith WN, Burnham T.Fireblocking textile insulation.USP 5776745,1998; Fujita M, Wakuta Y, Kumakawa S.Protective goods.USP 5935882,1999; Beckmann FD.Heat and Sound insulation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A41D13/00B32B5/26B32B27/08

Inventor 于伟东袁琴华黄鹤毛志平陈楠梁朱泉

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com