Knitted fabric of graphene and bio-based fiber and production method thereof

A technology for knitted fabrics and production methods, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of inability to realize multiple health care functions, coexistence, narrow use area, etc., and achieve improved quick-drying and one-way moisture-wicking effect, The effect of good skin-friendly performance and good moisture-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

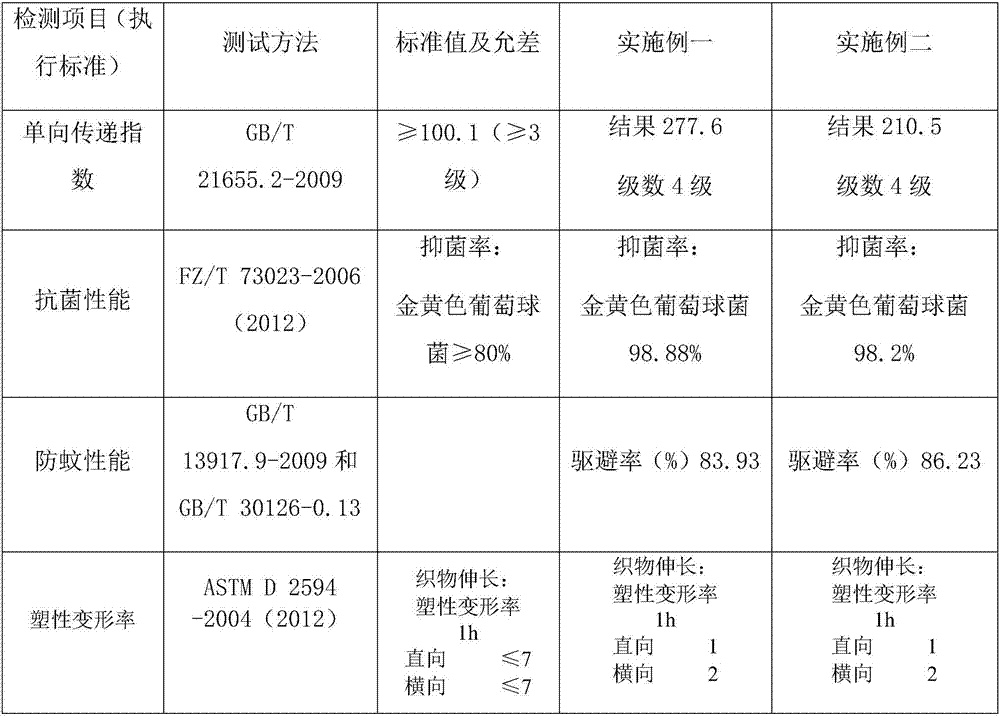

Embodiment 1

[0042] This implementation case provides a kind of health-care fabric, specifically: 40SJ graphene (cotton 65% / graphene viscose 35%)+50D elastic silk plating single-jersey cloth, design specification practical 68 " 170G / M2.

[0043] The production process is as follows: material preparation→weaving→pre-dyeing preparation→embryo determination→scouring→dyeing→intermediate testing→mosquito-proof finishing→one-way moisture-guiding printing→hydrophilic moisture absorption and quick-drying finishing→pre-shrinking→finished product inspection, the details are as follows :

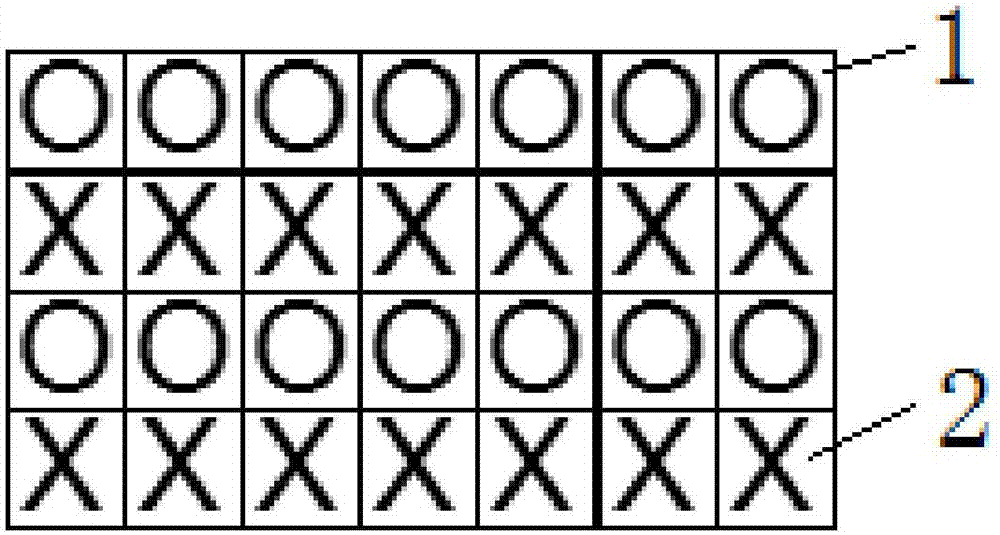

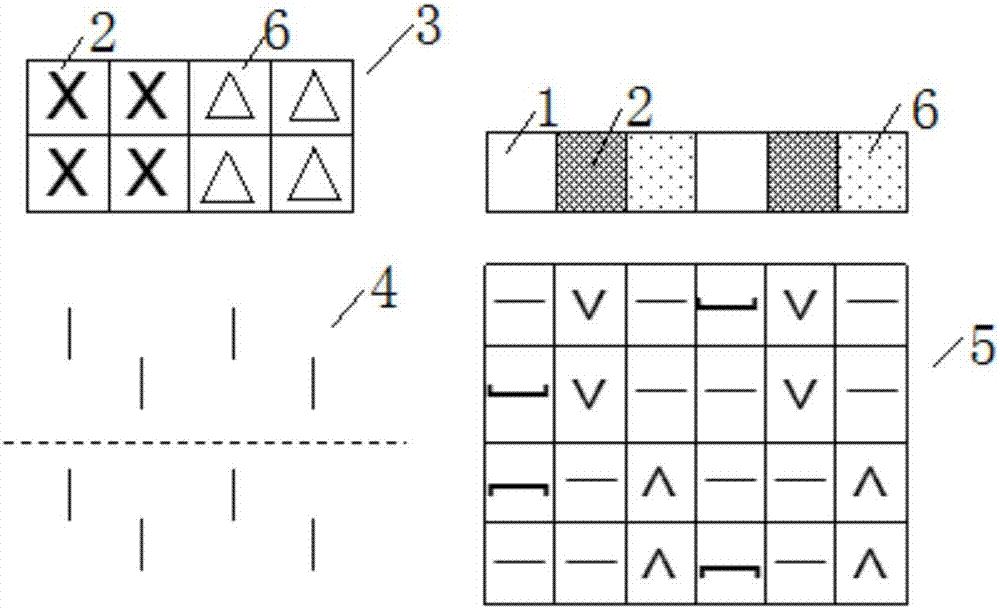

[0044](1) The weaving part of the process adopts a single-sided weft-knitted plain weave structure, the veil is made of 40 / 1'j graphene (cotton 65% / graphene viscose 35%) siro spinning material, and the bottom yarn is made of 50D sorona bio-based (Sorona), model: 38"x24G total number of needles: 2592 pin headers: 121212, such as figure 1 Shown is the schematic diagram of the structure, in which 1 is the sorona bio-...

Embodiment 2

[0051] This implementation case provides a health-care fabric, specifically 32SJ / 1J+40SJ graphene (cotton 65% / graphene viscose 35%)+50D elastic silk double-layer cloth, and the design specification is practical 72 "250 / M2.

[0052] The production process is as follows: material preparation→weaving→pre-dyeing preparation→embryo determination→scouring→dyeing→intermediate testing→mosquito-proof finishing→one-way moisture-guiding printing→hydrophilic moisture absorption and quick-drying finishing→pre-shrinking→finished product inspection, the details are as follows :

[0053] (1) The weaving part in the process adopts double-sided weft knitting structure, the inner layer is made of 40 / 1'j graphene (cotton 65% / viscose 35%) siro spinning material, and the middle connecting layer is made of 75d sorona bio-based fiber , the surface layer is made of 32SJ Vietnam Xindadong compact spinning. Machine type: 38"24G, total needle count: 2880, yarn length / needle included: 23CM / 40S: 26CM / 32S:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com