Environment-friendly high-temperature-resistant comfortable stretch yarn for garment stuffing and production method thereof

A production method and high-temperature-resistant technology, applied in textiles and papermaking, fiber mixing, fiber treatment, etc., can solve the problems that need to be improved, and achieve the effect of excellent warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

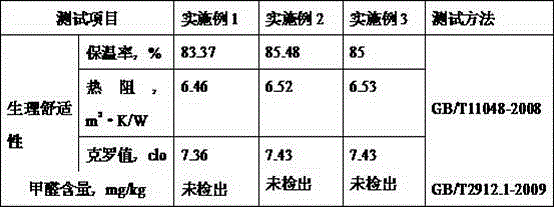

Examples

Embodiment 1

[0021] The manufacturing method of the environment-friendly and heat-resistant stretch elastic yarn for clothing filling comprises the following steps:

[0022] Step 1, mixing of materials: according to mass percentage, take respectively 10% corn fiber, 60% hollow fine denier polyester staple fiber and 30% Sorona fiber, totaling 100%; Hollow fine-denier polyester staple fiber and Sorona fiber are sent into a blender, mixed uniformly to obtain mixed fiber, wherein the hollow fine-denier polyester staple fiber is 1D hollow fine-denier polyester staple fiber;

[0023] Step 2, pretreatment: according to the mass percentage, respectively weigh 30% of nano silicon micropowder, 5% of Dendrobium officinale extract, 10% of ethanol and the remaining water, totaling 100%; Mix silicon micropowder, Dendrobium officinale extract, ethanol and water evenly to obtain a pretreatment mixture, raise the temperature to 45°C, immerse the mixed fiber obtained in step 1 into the pretreatment mixture,...

Embodiment 2

[0028] The manufacturing method of the environment-friendly and heat-resistant stretch elastic yarn for clothing filling comprises the following steps:

[0029] Step 1, stock preparation mixes: according to mass percentage, take respectively 13% corn fiber, 63% hollow fine denier polyester staple fiber and 24% Sorona Sorona fiber, total 100%; Will weigh the corn fiber, Hollow fine-denier polyester staple fiber and Sorona fiber are sent into a blender, mixed uniformly to obtain mixed fiber, wherein the hollow fine-denier polyester staple fiber is 1D hollow fine-denier polyester staple fiber;

[0030] Step 2, pretreatment: according to the mass percentage, respectively weigh 35% of nano silicon powder, 7% of Dendrobium officinale extract, 15% of ethanol and the rest of water, totaling 100%; Mix silicon micropowder, Dendrobium candidum extract, ethanol and water evenly to obtain a pretreatment mixture, raise the temperature to 40°C, immerse the mixed fiber obtained in step 1 into...

Embodiment 3

[0035] The manufacturing method of the environment-friendly and heat-resistant stretch elastic yarn for clothing filling comprises the following steps:

[0036] Step 1, mixing of materials: according to mass percentage, take respectively 15% corn fiber, 65% hollow fine denier polyester staple fiber and 20% Sorona Sorona fiber, totaling 100%; the weighed corn fiber, Hollow fine-denier polyester staple fiber and Sorona fiber are sent into a blender, mixed uniformly to obtain mixed fiber, wherein the hollow fine-denier polyester staple fiber is 1D hollow fine-denier polyester staple fiber;

[0037] Step 2, pretreatment: according to the mass percentage, respectively weigh 36% of nano silicon powder, 8.5% of Dendrobium officinale extract, 20% of ethanol and the remaining water, totaling 100%; Mix silicon micropowder, Dendrobium candidum extract, ethanol and water evenly to obtain a pretreatment mixture, raise the temperature to 45°C, immerse the mixed fiber obtained in step 1 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com