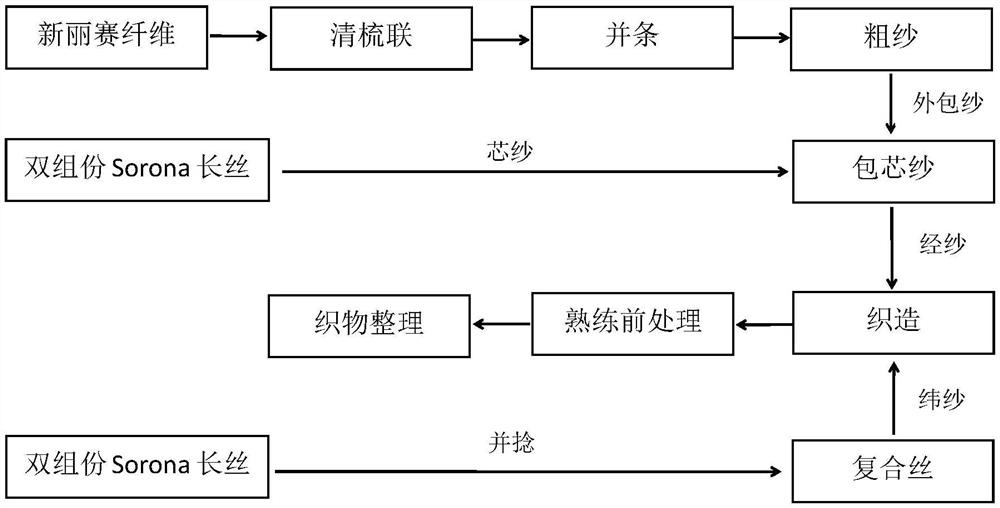

Preparation process of two-component Sorona side stretch fabric

A preparation process and two-component technology, applied in the field of textile fabrics, can solve the problems of spandex fabrics such as poor UV aging resistance, poor moisture absorption and air permeability, and low color fastness, and achieve good coloring effect, warp and weft elasticity and Good recovery, soft and comfortable feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Yarn specification

[0025] Outsourcing fiber: Xinli Sai fiber, 1.22dtex×8mm

[0026] Core yarn: 50D / 32F two-component Sorona filament

[0027] Composite yarn: two 50D / 32F bicomponent Sorona filaments

[0028] 2. Yarn technology

[0029] (1) Elastic core-spun yarn: Xinlisai staple fiber is made into roving through blowing-carding, drawing, and roving processes, and Xinlisai roving and bicomponent Sorona filament adopt the compact spinning core-spun yarn process. The outsourcing fiber roving enters the drafting mechanism of the spinning frame and merges with the core yarn at the front roller. The roving made of outsourcing fiber enters the drafting area through the bell mouth, and the Sorona filament is introduced into the godet wheel through the tension adjustment device, and is fed into the nip of the front roller after 1.5 times pre-drafting, merges with the outsourcing fiber, and twists on the spinning frame Next, a core-spun yarn is formed, the twist of the s...

Embodiment 2

[0036] 1. Yarn specification

[0037] Outsourcing fiber: cotton 229, micronaire value 3.6

[0038] Core yarn: 50D / 32F two-component Sorona filament

[0039] Composite yarn: one is 50D / 32F, one is 75D / 48F

[0040] 2. Yarn technology

[0041] (1) Elastic core-spun yarn: Cotton fiber is made into roving through blowing-carding, drawing, and roving processes. Cotton roving and bicomponent Sorona filaments are made of compact-spun core-spun yarn. The outsourcing fiber roving enters the drafting mechanism of the spinning frame and merges with the core yarn at the front roller. The roving made of outsourcing fiber enters the drafting area through the bell mouth, and the Sorona filament is introduced into the godet wheel through the tension adjustment device, and is fed into the nip of the front roller after 1.5 times pre-drafting, merges with the outsourcing fiber, and twists in the spinning frame Next, a core-spun yarn is formed, the twist of the spun yarn is 900 twists / meter, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com