Ecological cotton and production technology thereof

A production process and technology of ecological cotton, applied in the field of ecological cotton, can solve the problems of unsatisfactory washing performance, thermal insulation performance, unsatisfactory air permeability and moisture permeability, and rough product feel, so as to achieve better thermal insulation effect, improve thermal insulation effect, Guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and specific embodiments.

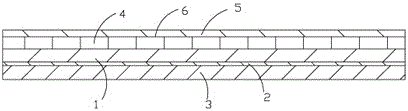

[0024] Such as figure 1 As shown, the present invention discloses an ecological cotton comprising a thermal cotton core 1, a 3D flocking layer arranged on the outer side of the thermal cotton core 1, and a soft close-fitting layer arranged on the inner side of the thermal cotton core 1. The 3D flocking layer The thickness of the fleece layer is 20%-30% of the thickness of the thermal cotton core 1, the thickness of the soft body layer is 30%-40% of the thickness of the thermal cotton core 1, and the thermal cotton core 1 is in weight percentage In total, it is made of 30% Sorona polymer fiber, 60% ultra-fine thermal fiber, and 10% virgin cotton fiber. The 3D flocking layer includes an elastic base cloth 6, which is set on the elastic by 3D flocking. The 3D flocking surface layer 5 on the surface of the base fabric 6, the vacuum cotton filling layer 4 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com