Production method of cool-feeling Sorona fiber

A production method and cool feeling technology, applied in the field of chemical fiber production and processing, can solve the problems of low research and development level, and achieve the effect of stable product quality, moderate elasticity, uniform elasticity and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

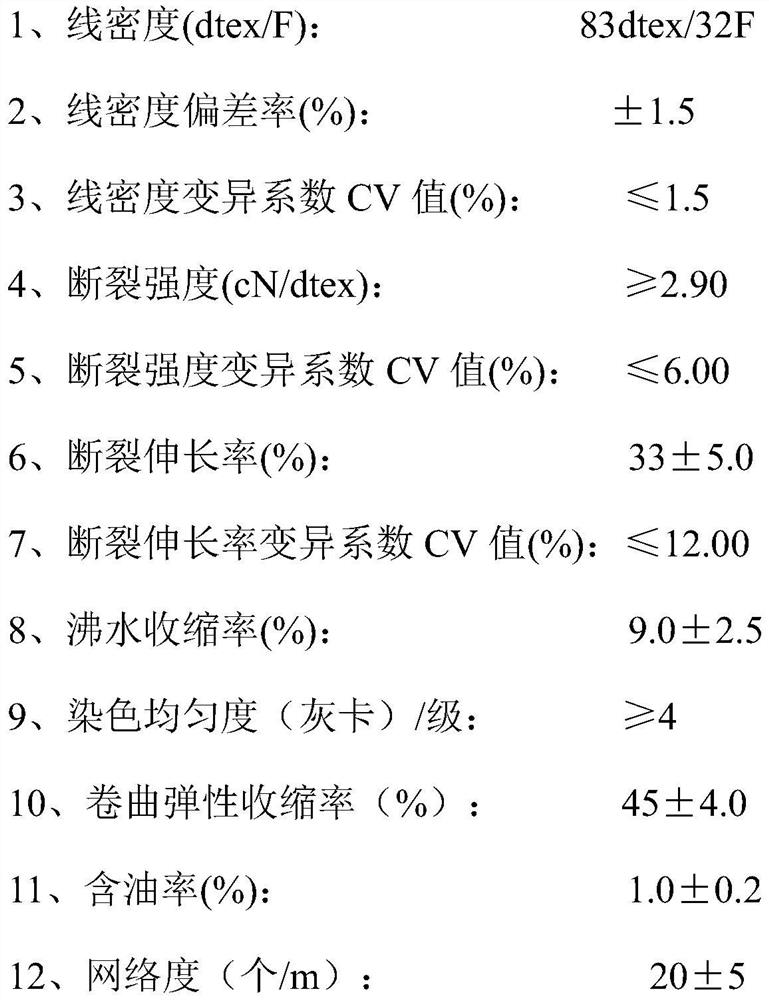

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] The production method of a kind of cool-feeling cable-elastic fiber involved in the present invention has the following production steps. The selected PET raw material is transported, pre-crystallized, dried, melted and extruded to form a spinning melt and enter the spinning through the box metering pump. Components; the selected PTT raw materials are conveyed, solid-phase viscosified, dried, melt-extruded, and filtered to form a spinning melt through a box metering pump for spinning components; PET spinning melt and PTT spinning melt are spinning The melt is collected in the filament assembly, and the collected melt is spun and then subjected to side blowing, oiling, pre-netting, drafting and setting, main network, winding forming, inspection, grading and packaging, and finished products. The drying temperature of PET chips is 165°C±5°C. The drying temperature of PTT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com