Preparation method of multifunctional blended yarn

A multi-functional, yarn technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of bacteria affecting human health, fabrics are easy to get wet and difficult to dry, cotton fabrics are damaged, etc., achieve antistatic elasticity, low production cost, high performance long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

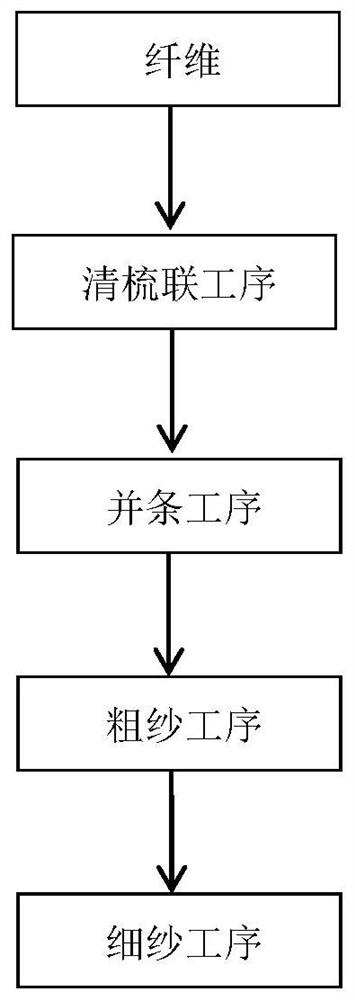

[0017] A preparation method of multifunctional yarn blended with bio-based synthetic fiber, cotton fiber and graphene polyester fiber, the specific steps are: packing and mixing Sorona fiber, cotton fiber and graphene polyester fiber according to a certain proportion, wherein Sorona The proportion of fiber is 20%, the proportion of cotton fiber is 60%, and the proportion of graphene polyester fiber is 20%. Produced through the spinning process. The process flow described is an ordinary ring spinning production process, which goes through a blowing-carding process, a drawing process, a roving process, a spinning process, and the like.

Embodiment 2

[0019] A preparation method of multifunctional yarn blended with bio-based synthetic fiber, cotton fiber and graphene polyester fiber, the specific steps are: packing and mixing Sorona fiber, cotton fiber and graphene polyester fiber according to a certain proportion, wherein Sorona The proportion of fiber is 20%, the proportion of cotton fiber is 60%, and the proportion of graphene polyester fiber is 20%. Produced through the spinning process. The process flow is a compact spinning production process, which goes through a blowing-carding process, a drawing process, a roving process, a spinning process, and the like.

Embodiment 3

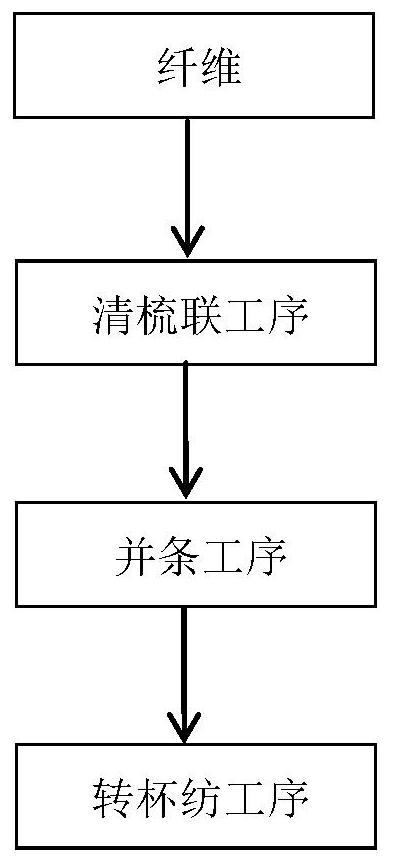

[0021] A preparation method of multifunctional yarn blended with bio-based synthetic fiber, cotton fiber and graphene polyester fiber, the specific steps are: packing and mixing Sorona fiber, cotton fiber and graphene polyester fiber according to a certain proportion, wherein Sorona The proportion of fiber is 20%, the proportion of cotton fiber is 60%, and the proportion of graphene polyester fiber is 20%. Produced through the spinning process. The process flow is a rotor spinning production process, which goes through a blowing-carding process, a drawing process, a rotor spinning process, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com