Dyeing and finishing process for Sorona-cotton lycra elastic French terry

A technology for sweater cloth and cotton pull frame, applied in the direction of dyeing method, solvent dyeing, liquid/gas/vapor removal, etc., can solve the problems of restricting the hand feeling and crease degree of the fabric, the economic loss and influence of the manufacturer, and the long process route, etc. Achieve the effect of broadening the scope of use and practicability, reducing the risk of forming creases, and making the cloth smooth and wrinkle-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

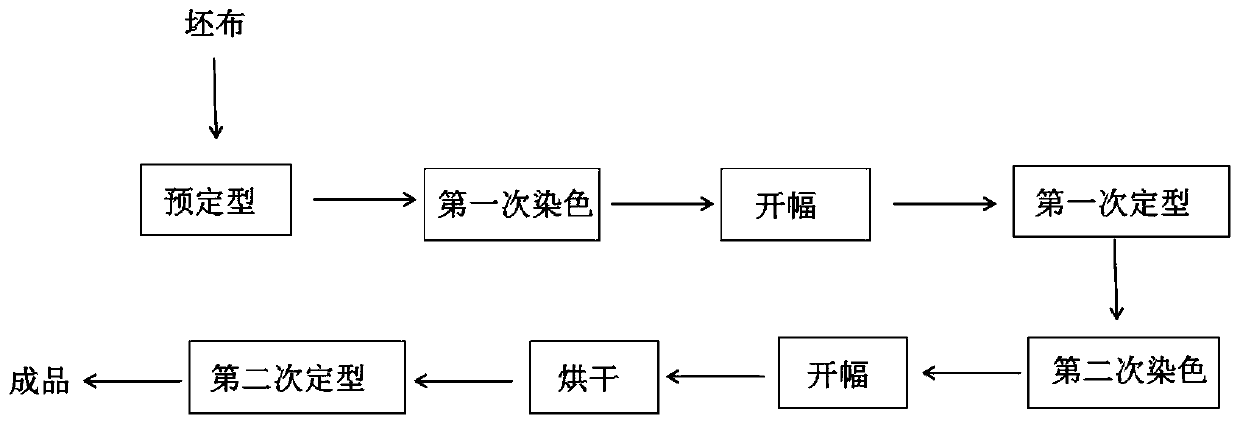

Method used

Image

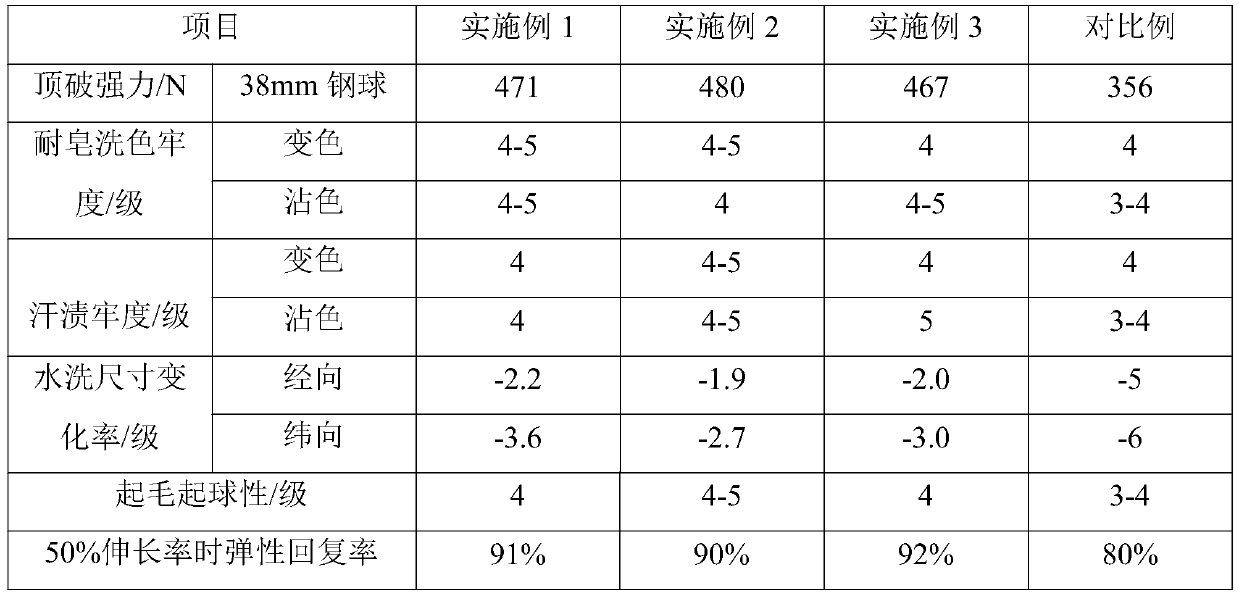

Examples

Embodiment 1

[0032] The dyeing and finishing process of Sorona cotton stretcher elastic sweater fabric includes the following steps:

[0033] (1) Pre-setting, place the Sorona cotton stretch hoodie loose cloth for 24 hours, so that it can fully retract naturally in a relaxed state. Use needle plate type setting machine to pre-set, the temperature is 185 ℃, and the vehicle speed is 20m / min.

[0034] (2) For the first dyeing, put the pre-shaped Sorona cotton stretch fabric into the clear water of the high-temperature and high-pressure airflow dyeing machine. After entering the fabric, the temperature is raised to 50°C, and the auxiliary agent before dyeing is added, and the dispersing and leveling agent is added first. RDN and anti-wrinkle agent BTO-R4, the content of dispersing and leveling agent RDN is 1g / L, the content of anti-wrinkle agent BTO-R4 is 1g / L, then add degreasing agent, its content is 1g / L, add glacial acetic acid to adjust the pH to 4.0 , and then add disperse dyes, fully d...

Embodiment 2

[0046] The dyeing and finishing process of Sorona cotton stretcher elastic sweater fabric includes the following steps:

[0047] (1) Pre-setting, place the Sorona cotton stretcher elastic sweater cloth loose cloth for 27 hours, so that it can fully retract naturally in a relaxed state. Use a needle plate type setting machine to pre-set, the temperature is 180 ° C, and the speed is 23m / min.

[0048] (2) For the first dyeing, put the pre-shaped Sorona cotton stretch fabric into the clear water of the high-temperature and high-pressure airflow dyeing machine. After entering the fabric, the temperature is raised to 50°C, and the auxiliary agent before dyeing is added, and the dispersing and leveling agent is added first. RDN and anti-wrinkle agent BTO-R4, the content of dispersing and leveling agent RDN is 1g / L, the content of anti-wrinkle agent BTO-R4 is 1g / L, then add degreasing agent, its content is 1g / L, add glacial acetic acid to adjust the pH to 4.5 , and then add disperse ...

Embodiment 3

[0058] The dyeing and finishing process of Sorona cotton stretcher elastic sweater fabric includes the following steps:

[0059] (1) Pre-setting, place the Sorona cotton stretcher elastic sweater loose cloth for 31 hours, so that it can fully retract naturally in a relaxed state. Use a pin plate type setting machine to pre-set, the temperature is 190 ° C, and the speed is 25 m / min.

[0060] (2) For the first dyeing, put the pre-shaped Sorona cotton stretch fabric into the clear water of the high-temperature and high-pressure airflow dyeing machine. After entering the fabric, the temperature is raised to 50°C, and the auxiliary agent before dyeing is added, and the dispersing and leveling agent is added first. RDN and anti-wrinkle agent BTO-R4, the content of dispersing and leveling agent RDN is 1g / L, the content of anti-wrinkle agent BTO-R4 is 1g / L, then add degreasing agent, its content is 1g / L, add glacial acetic acid to adjust the pH to 4.3 , and then add disperse dyes, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com