Sheet arranging and conveying mechanism

A conveying mechanism and sheet technology, which is applied in transportation and packaging, medical science, clothing, etc., can solve the problems of increased risk of loss of control of the back ear, and achieve the effects of reducing the risk of wrinkles, reducing production costs, and facilitating operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

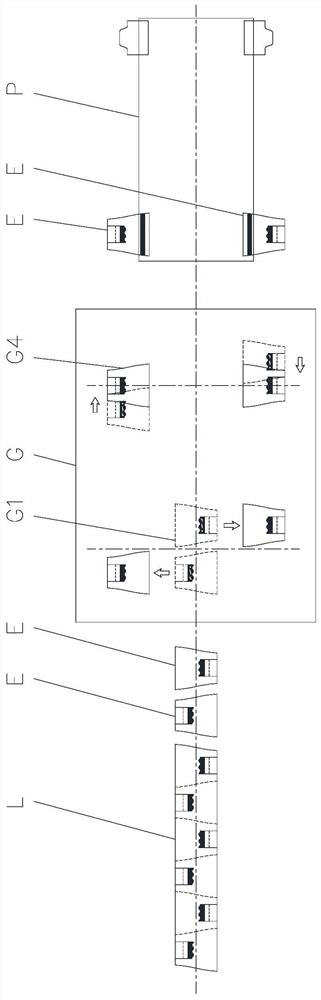

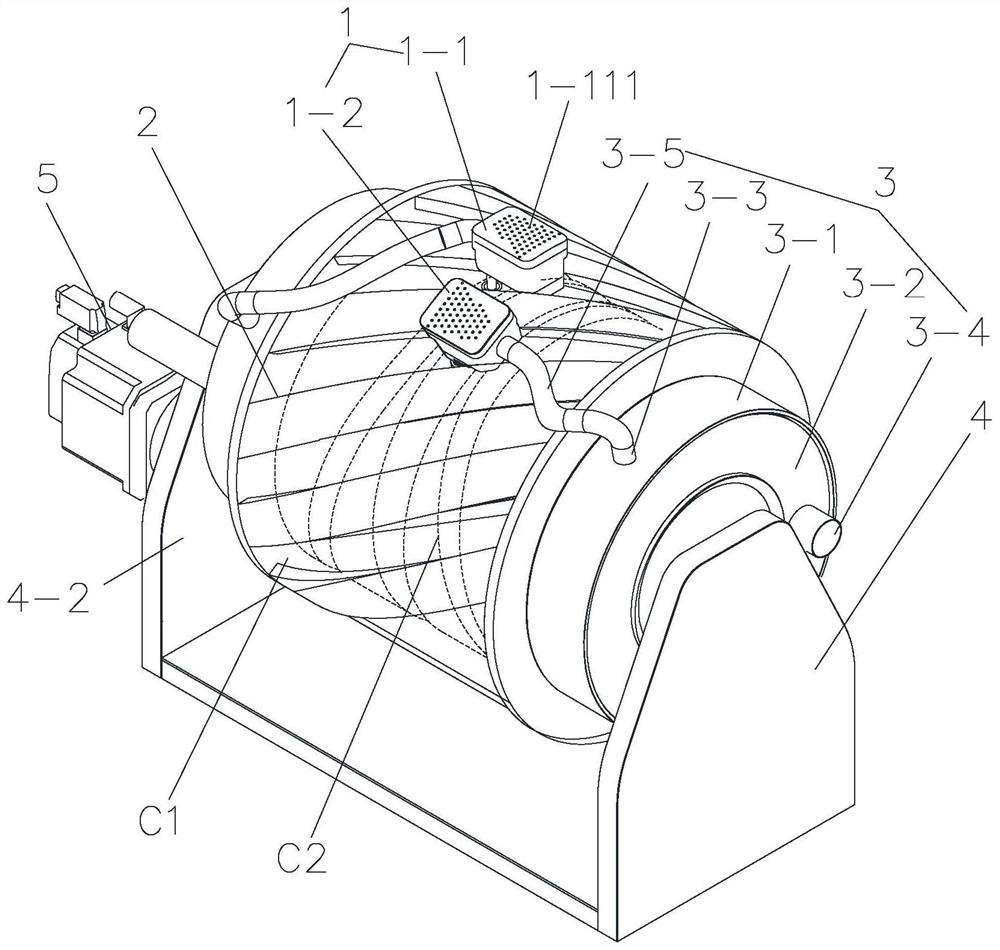

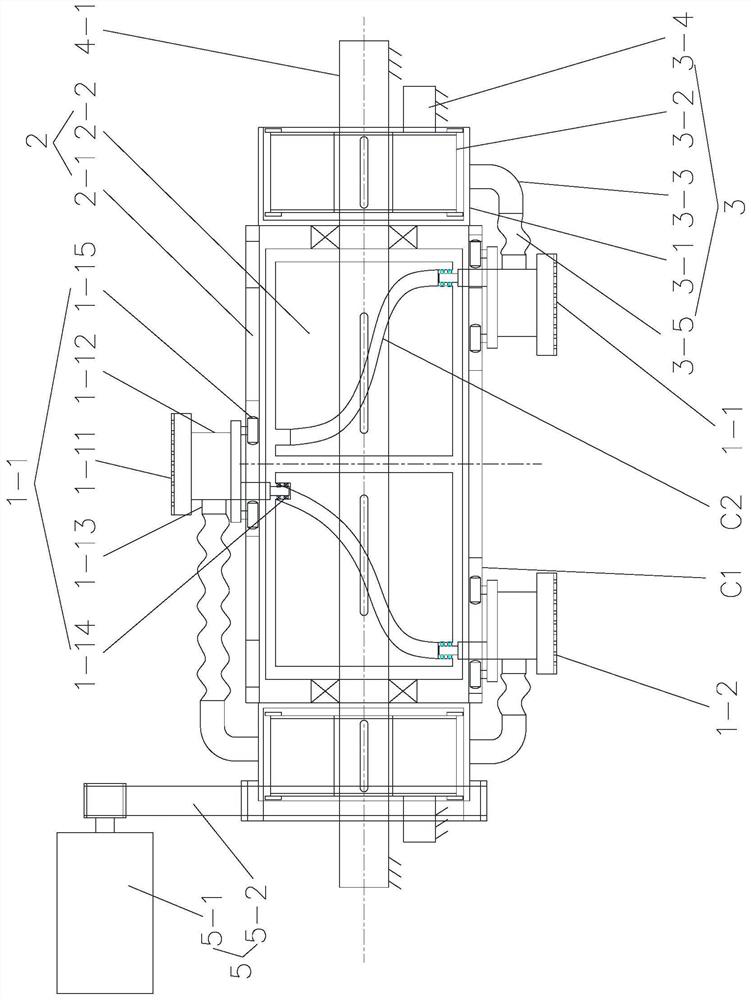

[0024] Such as Figure 1-7 As shown, a sheet material arrangement conveying mechanism includes a suction cup assembly 1 and an arrangement assembly 2, and the suction cup assembly 1 includes an inner suction cup 1-1 and an outer suction cup 1-2, and the number of the suction cup assembly 1 in this embodiment There are three groups, that is, three pairs of inner suction cups 1-1 and outer suction cups 1-2, and the inner suction cups 1-1 and outer suction cups 1-2 have the same structure, and all include suction boxes 1-12. The bottom of the suction box 1-12 is provided with a first guide wheel 1-14 and a second guide wheel 1-15, and the side of the suction box 1-12 is provided with a suction interface 1-13, and the suction The top of the box 1-12 is provided with a suction cup cover 1-11, and the suction cup cover 1-11 is penetrated with a number of suction holes 1-111, and the arrangement of the suction cup holes 1-111 matches the shape of the back ear E , the suction hole 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com