Processing method of Sorona and silk clothes fabric

A processing method and fabric technology, applied in the direction of dyeing method, textile material contact export textile material processing, textile and paper making, etc., to achieve the effect of excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

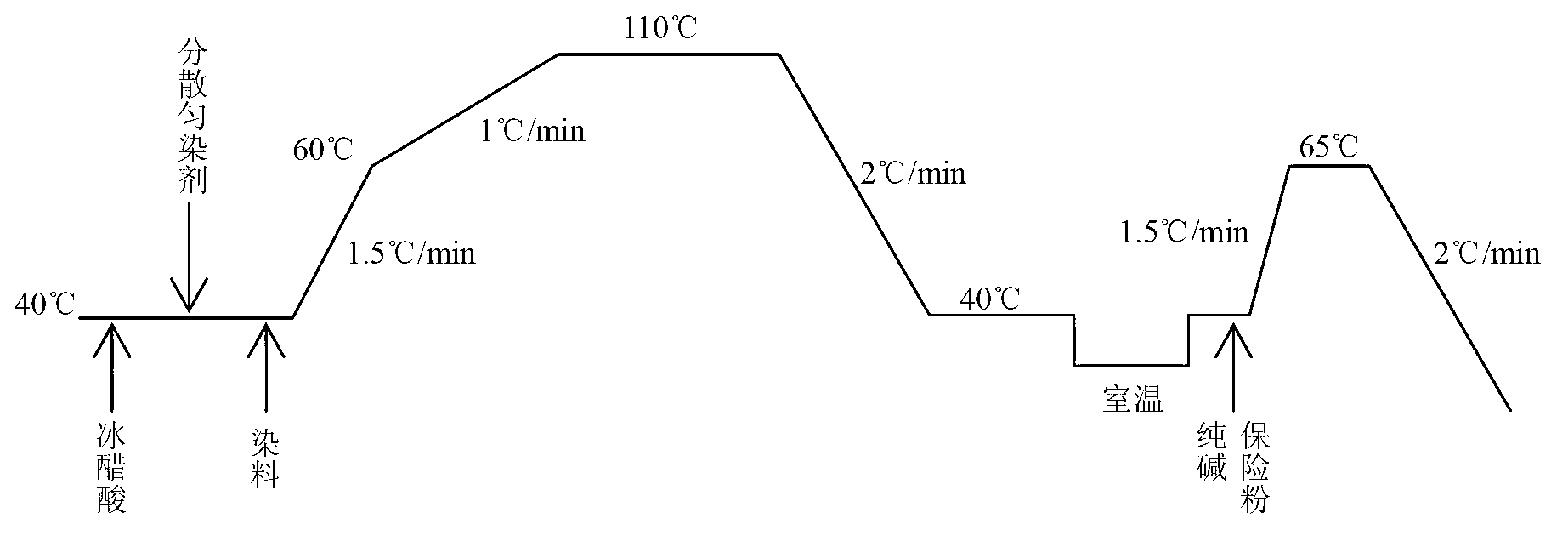

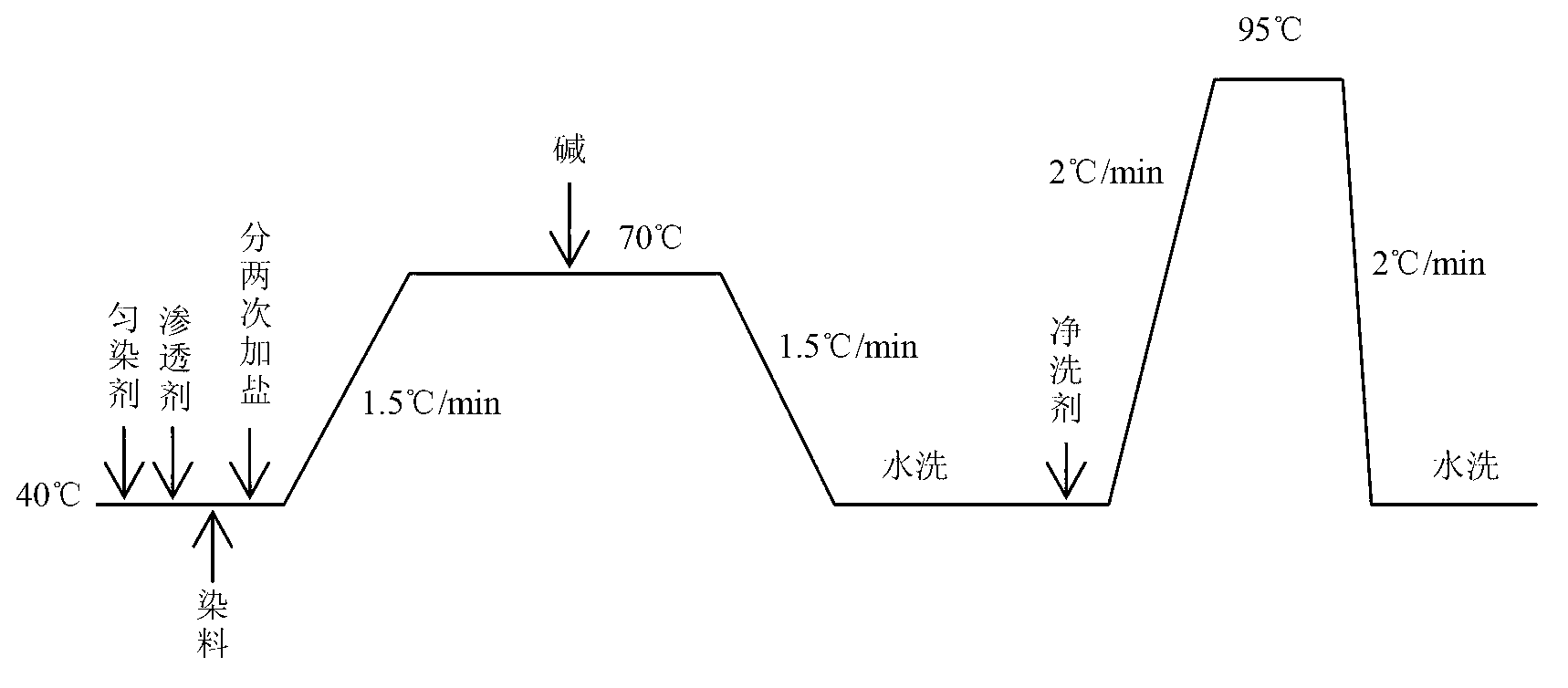

[0045] Embodiments of the present invention include the following steps:

[0046] 1) Selection of raw materials: 16D mulberry silk, 75D viscose filament and 45D Sorona filament.

[0047] Sorona is the name of the fiber registered after the research and development of DuPont in the United States. It is a common English name in the world; 16D is 16 denier, which means the fineness of the yarn, and is a common name in the textile industry; 45D refers to a strand of 45D yarn ( It can be made by twisting 48 microfiber filaments);

[0048] 2) Splicing: 16D mulberry silk, 75D viscose filament and 45D Sorona filament are firstly twisted separately and then merged to form a composite yarn; The company's NO363 two-for-one twister is two-for-one twisting, and the combination can be combined with the NO23 high-speed doubling machine of Japan MUTARA Company.

[0049] 3) Dyeing silk: first pre-treat the composite silk obtained in step 2), and then carry out high-temperature dyeing of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contacts | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com