Hydrophilic small-layer-difference smoothing agent for cheese and preparation method of hydrophilic small-layer-difference smoothing agent

A technology of cheese and smoothing agent, applied in the direction of plant fiber, light-resistant fiber, fiber treatment, etc., can solve the problem of increasing the difference between the layers of the cheese, reducing the difference between the inner and outer layers, excellent hydrophilicity, and a small layer difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 2

[0119] Preparation of synthetic wax 2 used in Example 2:

[0120] A. 172.31gC11 alcohol and 284.48g stearic acid are added in the reactor;

[0121] B. Heating to 140°C while blowing nitrogen gas; after 6 hours of reaction, the acid value of the sample measured was 11.3mgKOH / g, and the reaction was judged to be complete

[0122] C. Pass cooling water, cool down to 80°C, discharge while hot, slice and pack.

[0123] Softener 2 used in Preparation Example 2:

[0124] A. 284.48g stearic acid and 50g diethanolamine are added in the reactor;

[0125] B. Heating to 140°C while passing nitrogen gas; reacting for 6 hours, taking a sample and measuring the acid value of the sample as 14.8mgKOH / g, judging that the reaction is complete;

[0126] C. Pass cooling water, cool down to below 50°C, and pack it out.

preparation Embodiment 3

[0127] Preparation of synthetic wax 3 used in Example 3:

[0128] A. 270g n-18 alcohol and 180g capric acid are added in the reactor;

[0129] B. Heating to 200°C while passing nitrogen gas; after 2.5 hours of reaction, the acid value of the sample measured was 9.7mgKOH / g, and the reaction was judged to be complete;

[0130] C. Pass cooling water, cool down to 80°C, discharge while hot, slice and pack.

[0131] Softener 3 used in preparation example 3:

[0132] A.255g 2-hexadecenoic acid and 60g diethanolamine are added in the reactor;

[0133] B. Heating to 200°C while passing nitrogen gas; reacting for 2 hours, taking a sample and measuring the acid value of the sample as 1.3mgKOH / g, judging that the reaction is complete;

[0134] C. Pass cooling water, cool down to below 50°C, and pack it out.

Embodiment 1

[0136] A) 140g oxidized Fischer-Tropsch wax A2 (Sasol oxidized Fischer-Tropsch wax), 35g56# semi-refined paraffin (Takahashi Petrochemical), 35g synthetic wax 1, 20g softener 1, 20g fatty alcohol polyoxyethylene ether AE0- 9 (Real Madrid), 40g of customized block emulsifier (C14 alcohol 10EO6PO3EO), 7g of stearylamine polyoxyethylene ether A-C 1815 (Real Madrid), 5g of potassium hydroxide were added to the reaction kettle;

[0137] B) After the temperature rises to 50°C, start stirring and continue to heat up to 90°C;

[0138] C) Slowly add 678g of 95°C hot water in 5 times, heat to keep the temperature in the kettle above about 95°C, and stir and emulsify;

[0139] D) rapid cooling to room temperature;

[0140] E) Add 20g of cationic regulator (Huajie Chemical) into the reaction kettle while stirring, and stir evenly;

[0141] F) Discharging and filtering to obtain a white slightly turbid translucent emulsion.

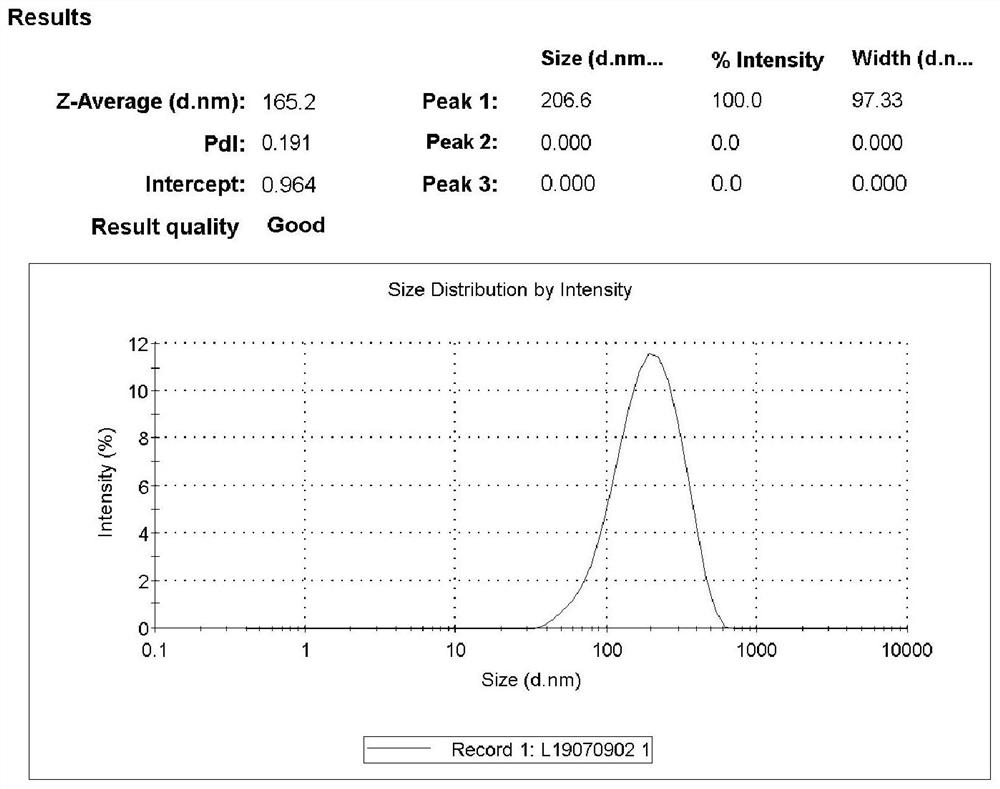

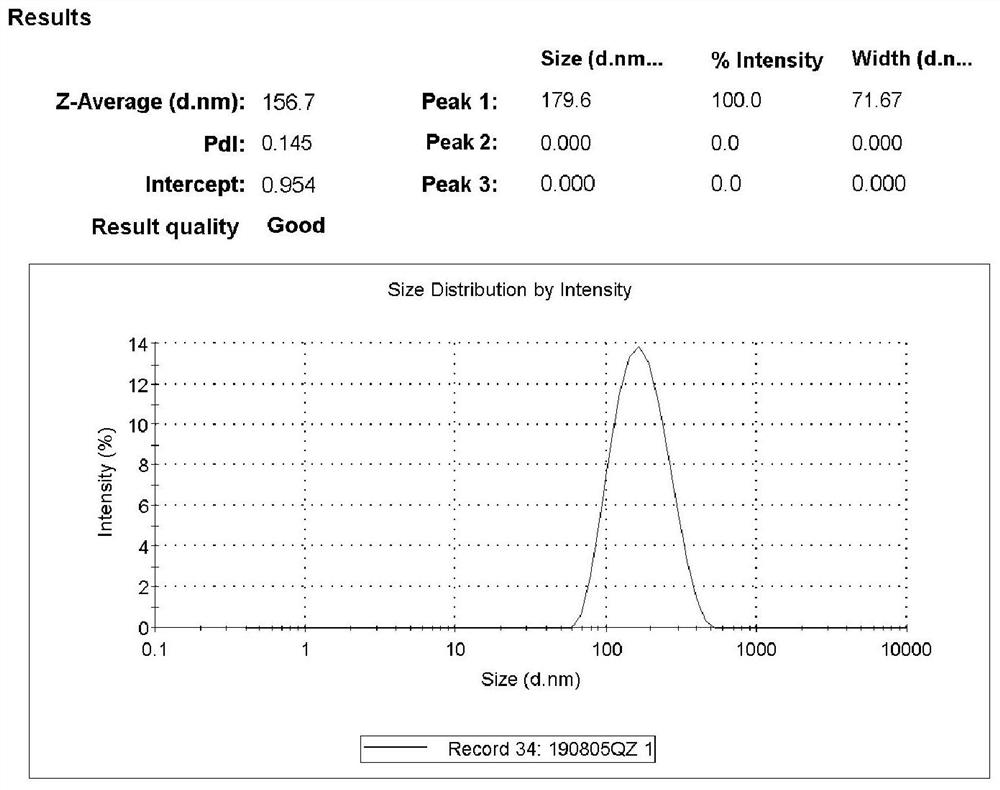

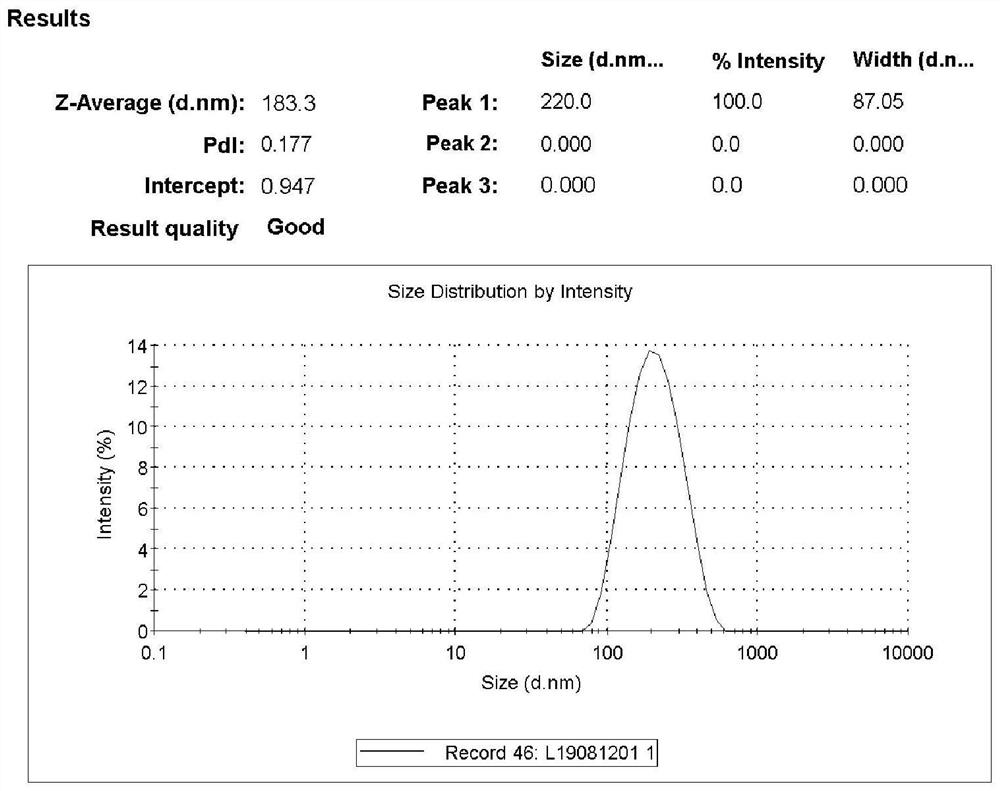

[0142] The prepared smoothing agent is configured into a 0.2w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com