Method for processing quick-drying air-permeable fabric with double surfaces functioning differently

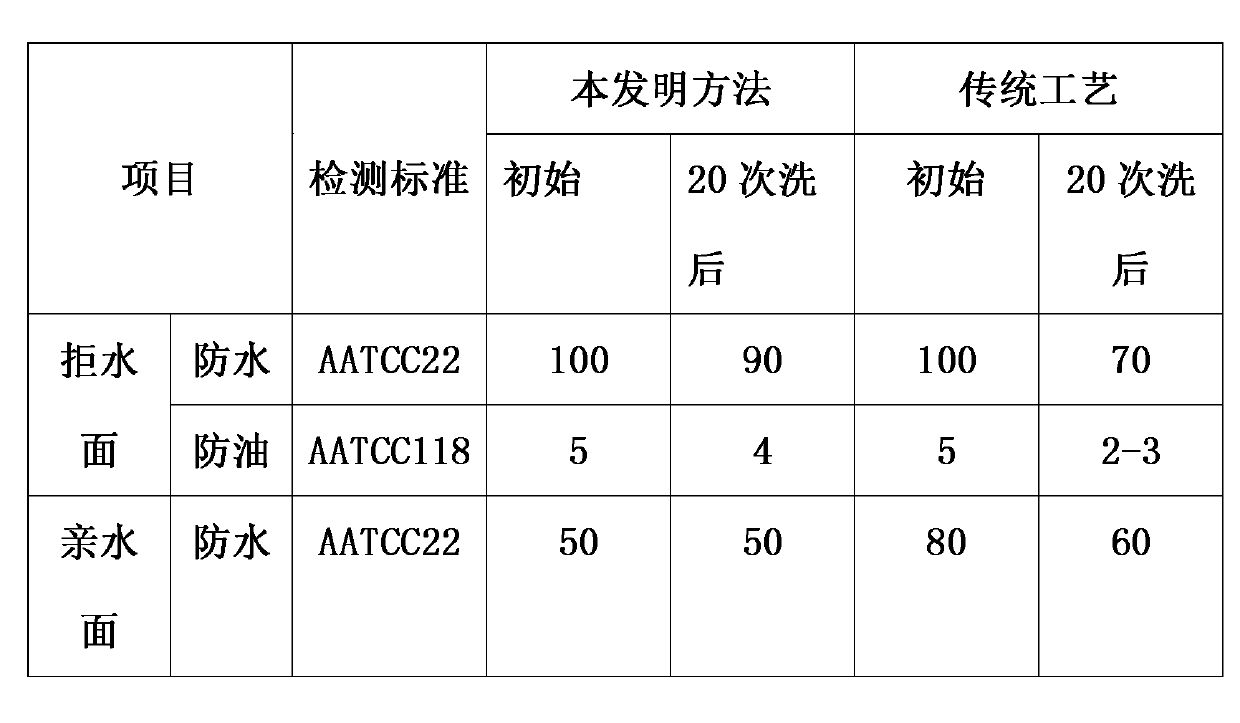

A processing method and a breathable technology, applied in the field of fabric processing, can solve the problems of insufficient washing resistance and poor stability, and achieve the effects of improving hand feel, improving washing resistance and ensuring uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1. A method for processing a quick-drying air-permeable fabric with different effects on both sides, comprising the following steps:

[0027] ① For pretreatment of SORONA fiber textiles, use a compound enzyme preparation containing 2-10g / L compound alkaline pectinase, 2-5g / L amylase, and 3-10g / L non-ionic emulsifier with a pH of 7-9 Pre-treat the textiles to replace the traditional desizing and scouring process, and add 1 gram of Tween T80 and 1 gram of sodium tripolyphosphate per kilogram of the compound enzyme preparation when the compound enzyme preparation is used. The textile is soaked and rolled at 40-60°C for multiple times with the compound enzyme preparation, rolled up and kept at 30-60°C for 4-24 hours, then washed with hot water, bleached, mercerized and whitened to obtain material A; press Mass percentage, described compound alkaline pectinase comprises 85% alkaline pectinase and 15% hydroxymethyl cellulase;

[0028] ② Pigment printing is carried o...

Embodiment 2

[0032] Example 2. A method for processing a quick-drying air-permeable fabric with different effects on both sides, comprising the following steps:

[0033] ① For pretreatment of SORONA fiber textiles, use a compound enzyme preparation containing 2-10g / L compound alkaline pectinase, 2-5g / L amylase, and 3-10g / L non-ionic emulsifier with a pH of 7-9 Pre-treat the textiles to replace the traditional desizing and scouring process, and add 1 gram of Tween T80 and 1 gram of sodium tripolyphosphate per kilogram of the compound enzyme preparation when the compound enzyme preparation is used. The textile is soaked and rolled at 40-60°C for multiple times with the compound enzyme preparation, rolled up and kept at 30-60°C for 4-24 hours, then washed with hot water, bleached, mercerized and whitened to obtain material A; press Mass percentage, described compound alkaline pectinase comprises 85% alkaline pectinase and 15% hydroxymethyl cellulase;

[0034] ② Pigment printing is carried o...

Embodiment 3

[0038] Example 3. A method for processing a quick-drying air-permeable fabric with different effects on both sides, comprising the following steps:

[0039] ① For pretreatment of SORONA fiber textiles, use a compound enzyme preparation containing 2-10g / L compound alkaline pectinase, 2-5g / L amylase, and 3-10g / L non-ionic emulsifier with a pH of 7-9 Pre-treat the textiles to replace the traditional desizing and scouring process, and add 1 gram of Tween T80 and 1 gram of sodium tripolyphosphate per kilogram of the compound enzyme preparation when the compound enzyme preparation is used. The textile is soaked and rolled at 40-60°C for multiple times with the compound enzyme preparation, rolled up and kept at 30-60°C for 4-24 hours, then washed with hot water, bleached, mercerized and whitened to obtain material A; press Mass percentage, described compound alkaline pectinase comprises 85% alkaline pectinase and 15% hydroxymethyl cellulase;

[0040] ② Pigment printing is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com