Preparation process of denim yoga fabric

A production process, yoga technology, applied in the direction of fabric surface trimming, yarn, thorn pattern, etc., can solve the problems of airtightness, thick denim fabric, unsatisfactory sportswear, etc., to achieve improved air permeability and elasticity, and high color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

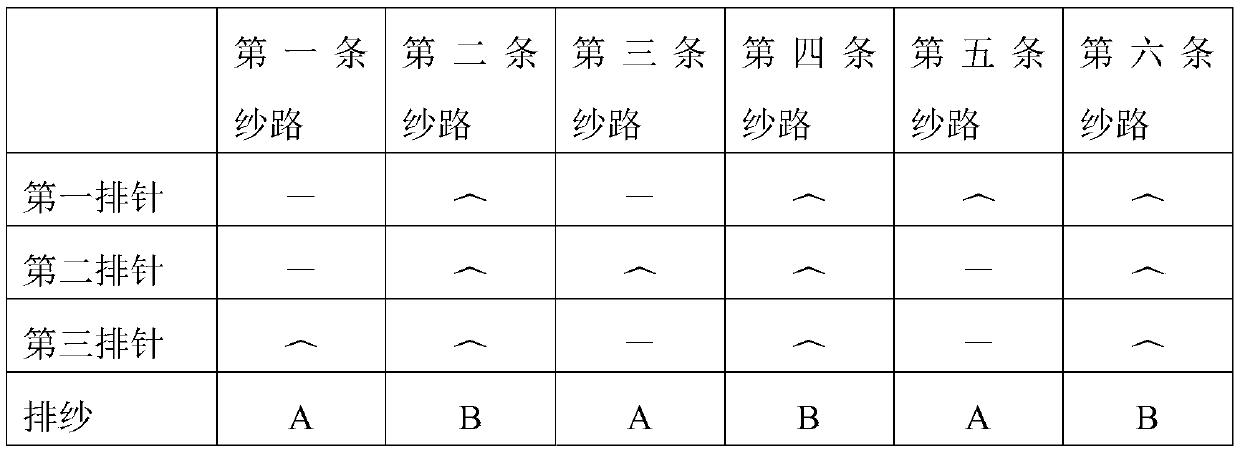

[0031] A kind of manufacturing process of denim yoga fabric of the present embodiment, comprises the steps:

[0032] S1 material selection: choose 40S / 1 cellulose fiber-wrapped polyester core-spun yarn, 100D / 34F Sorona (also known as SORONA) and 70D spandex as raw materials; among them, the cellulose fiber-wrapped polyester core-spun yarn includes polyester core Layer and cellulose fiber cortex, the cellulose fiber cortex is a blended yarn of modal and fine cotton;

[0033] Wherein, the weight proportion of the core-spun yarn covered with polyester by cellulose fiber is 37%, and the weight proportion of polyester in the core-spun yarn wrapped with polyester by cellulose fiber is 45%;

[0034] In addition, in other alternative embodiments, the weight ratio of the cellulose fiber-wrapped polyester core-spun yarn can be 30%, 31%, 32%, 33%, 34%, 35%, 36%, 38%, 39% %, 40%; in other alternative embodiments, the weight proportion of the polyester core layer in the core-spun yarn cov...

Embodiment 2

[0060] The manufacturing process of the denim yoga fabric of the present embodiment is basically the same as that of embodiment 1, and its difference is:

[0061] In this embodiment, 40S / 1 cellulose fibers are used to wrap polyester core-spun yarn, and 75D / 34F SORONA and 70D spandex are used to weave the knitted gray fabric of twill single jersey.

Embodiment 3

[0063] The manufacturing process of the denim yoga fabric of the present embodiment is basically the same as that of embodiment 1, and its difference is:

[0064] The present embodiment adopts the core-spun yarn of 40S / 1 cellulose fiber wrapping polyester, and 75D / 34F SORONA and 70D spandex to weave into the knitted gray fabric of twill weave single sweater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com