Shoe upper patter forming method and shoe uppers thereof

A pattern forming and shoe upper technology, which is applied in the field of footwear manufacturing, can solve the problems of large deformation and deviation, and achieve the effects of small deformation, high resolution and high definition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

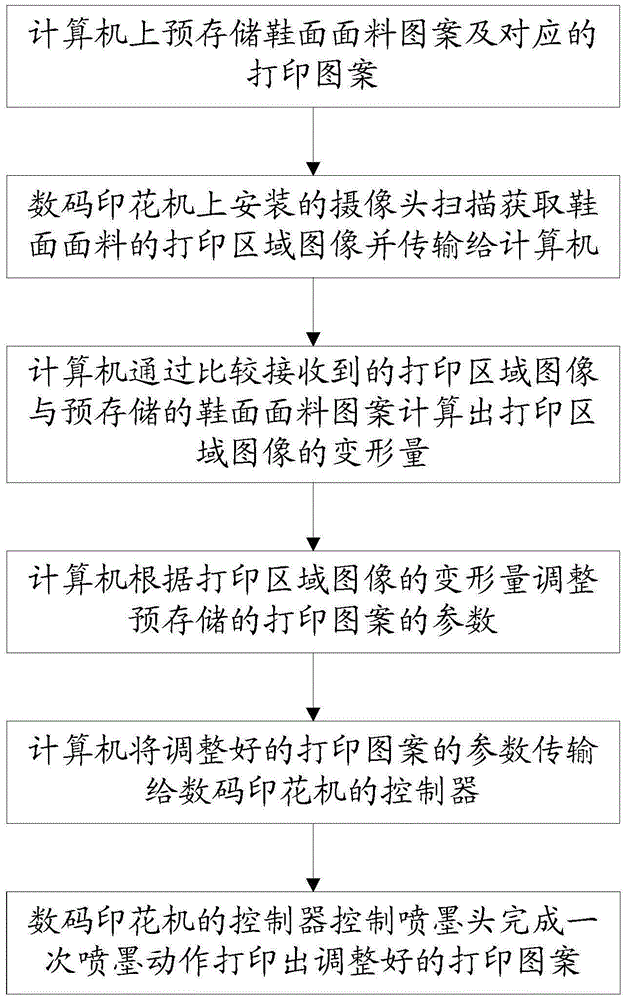

[0070] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0071] A shoe upper pattern molding method, the method steps are:

[0072] The upper fabric pattern and the corresponding printing pattern are pre-stored on the S1 computer;

[0073] The camera installed on the S2 digital printing machine scans to obtain the printed area image of the upper fabric and transmits it to the computer;

[0074] The S3 computer calculates the deformation of the printed area image by comparing the received printed area image with the pre-stored shoe upper fabric pattern. The printed area image is consistent with the area where the inkjet head completes an inkjet action, specifically:

[0075] The computer receives and stores the print area image;

[0076] Comparing the printed area image with the pre-stored upper fabric pattern, finding the area with the highest similarity with the printed area image in the pre-stored upper fabric pattern, specifically:

[0077] Selectin...

Embodiment 2

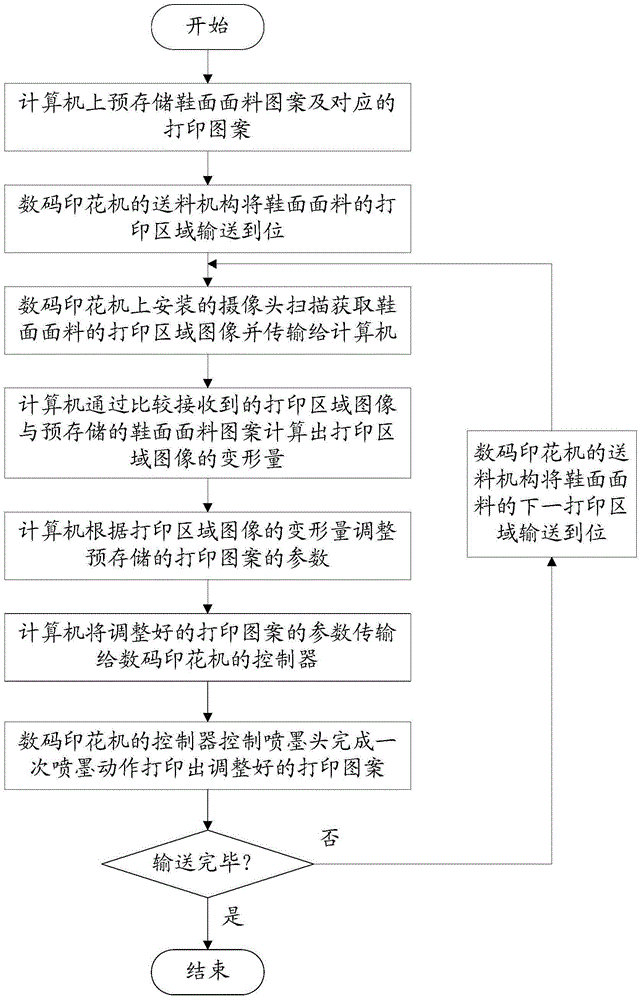

[0091] Please refer to figure 2 , the second embodiment of the present invention is:

[0092] A shoe upper pattern molding method, the method steps are:

[0093] The upper fabric pattern and the corresponding printing pattern are pre-stored on the S1 computer;

[0094] The feeding mechanism of the S2 digital printing machine transports the printing area of the shoe upper fabric into place;

[0095] The camera installed on the S3 digital printing machine scans to obtain the printed area image of the upper fabric and transmits it to the computer;

[0096] The S4 computer calculates the amount of deformation of the printed area image by comparing the received printed area image with the pre-stored upper fabric pattern;

[0097] The S5 computer adjusts the parameters of the pre-stored printing pattern according to the amount of deformation of the printing area image;

[0098] The S6 computer transmits the adjusted printing pattern parameters to the controller of the digital...

Embodiment 3

[0103] Please refer to image 3 , Embodiment three of the present invention is:

[0104] A shoe upper, using the shoe upper made by the above method, the shoe upper includes a shoe upper fabric 1 and a spray pattern layer 2 made by a digital printing machine, the pattern of the spray pattern layer 2 has high pixel resolution , the pattern is clear, and the relative deformation between the pattern of the spray pattern layer 2 and the upper fabric 1 is small.

[0105] To sum up, the shoe upper pattern forming method and the shoe upper provided by the present invention find out the area with the highest similarity among the pre-stored shoe upper fabrics according to the characteristic area of the upper fabric, and adopt the method of taking coordinates and angle features according to the similarity. The image of the area with the highest degree of accuracy determines the deformation of the printing area of the upper fabric. The method of mesh division is used to adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com