Nanometer hybridized phosphor in core-shell structure and its prepn process

A technology of nano-fluorescent powder and shell structure, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of reducing the growth rate of complexes, low solubility, complex preparation process, etc., and achieves excellent application performance, high luminous intensity, single good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

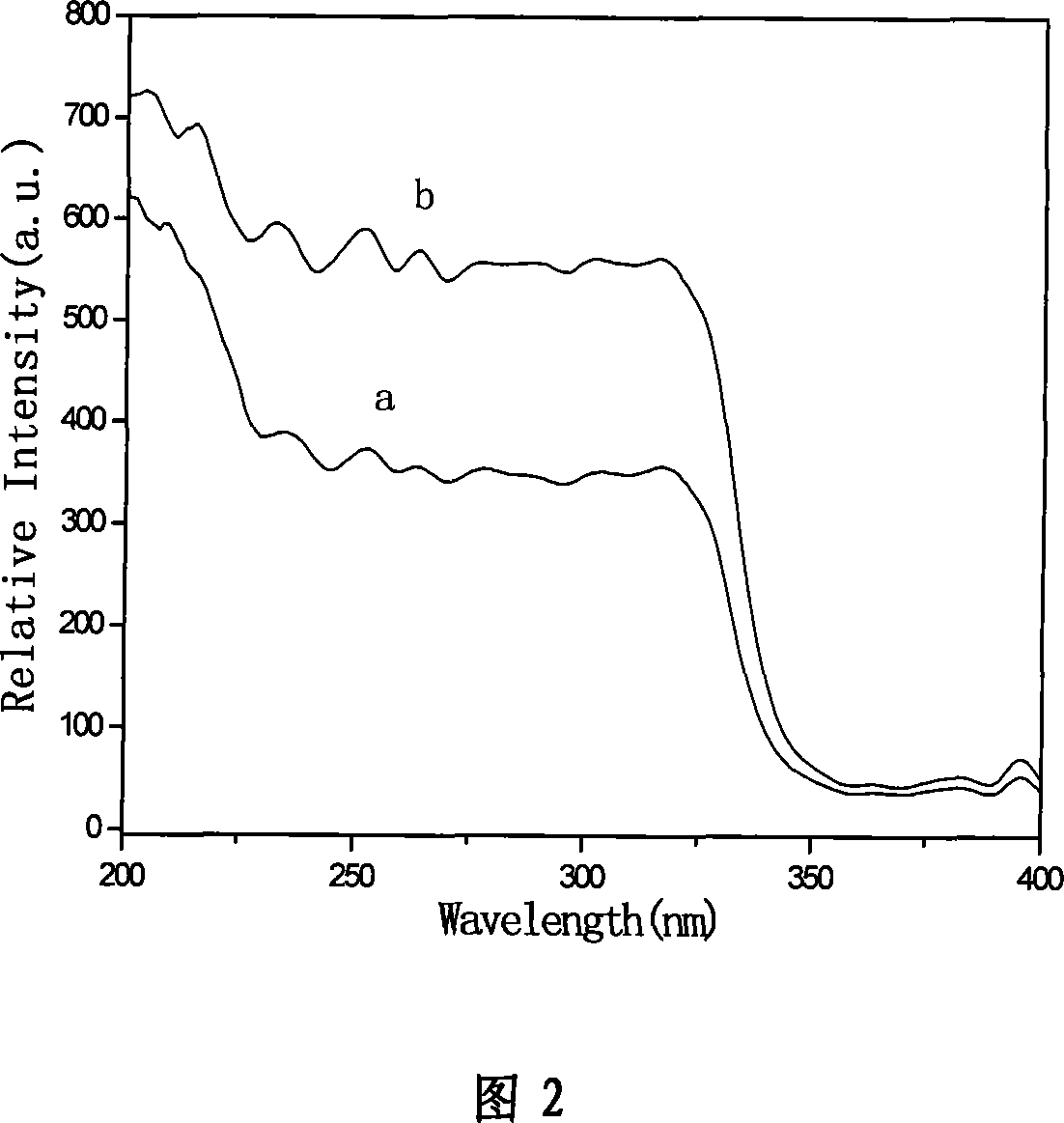

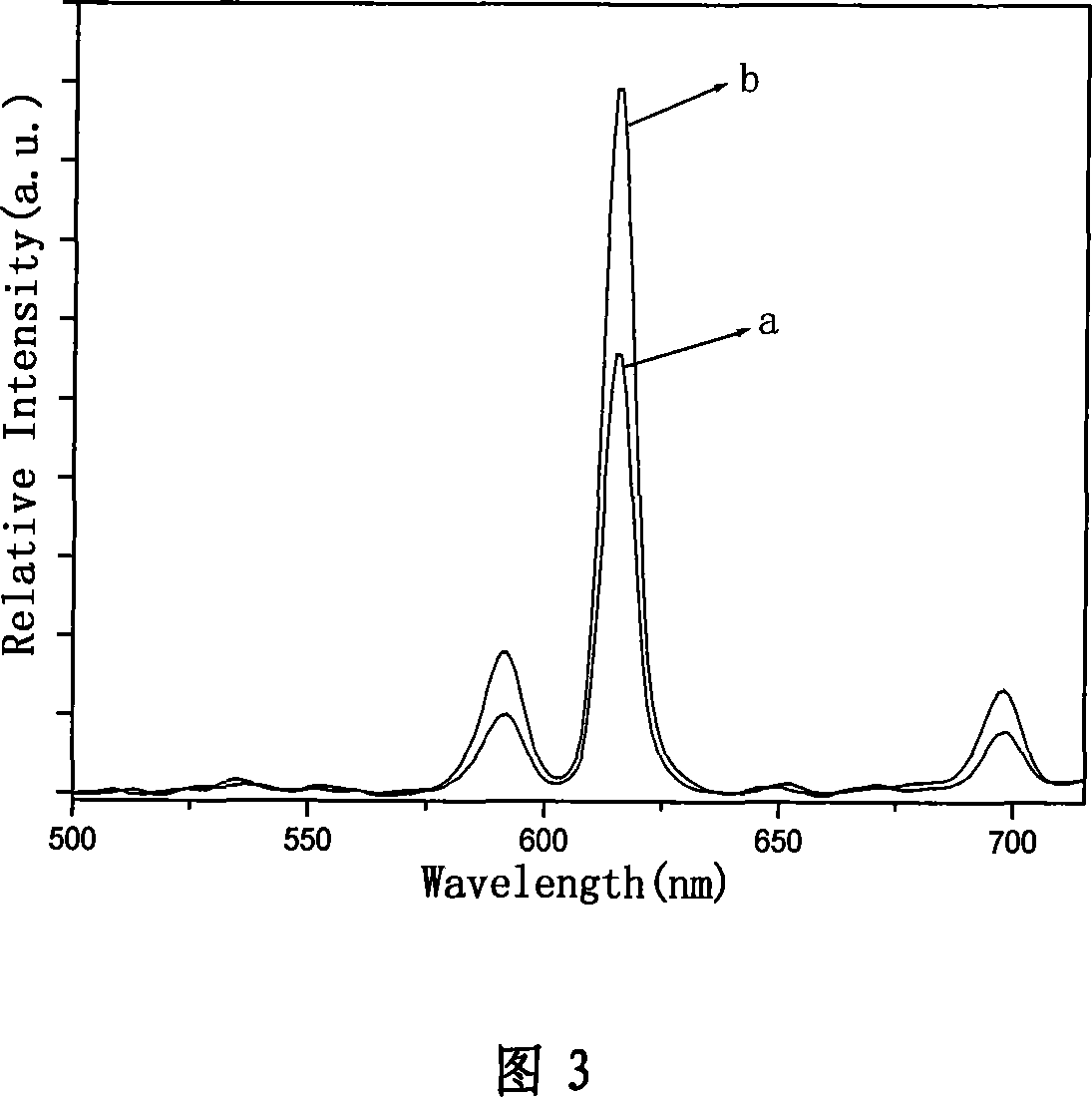

[0031] Add 15ml of ammonium terephthalate solution into a 100ml flask, slowly add 10ml of 0.1M EuCl dropwise under magnetic stirring 3 solution; react in a water bath at 60°C for 3 hours; centrifuge the product and wash it three times with absolute ethanol; dry at 80°C for 8 hours to obtain the europium-terephthalic acid rare earth complex.

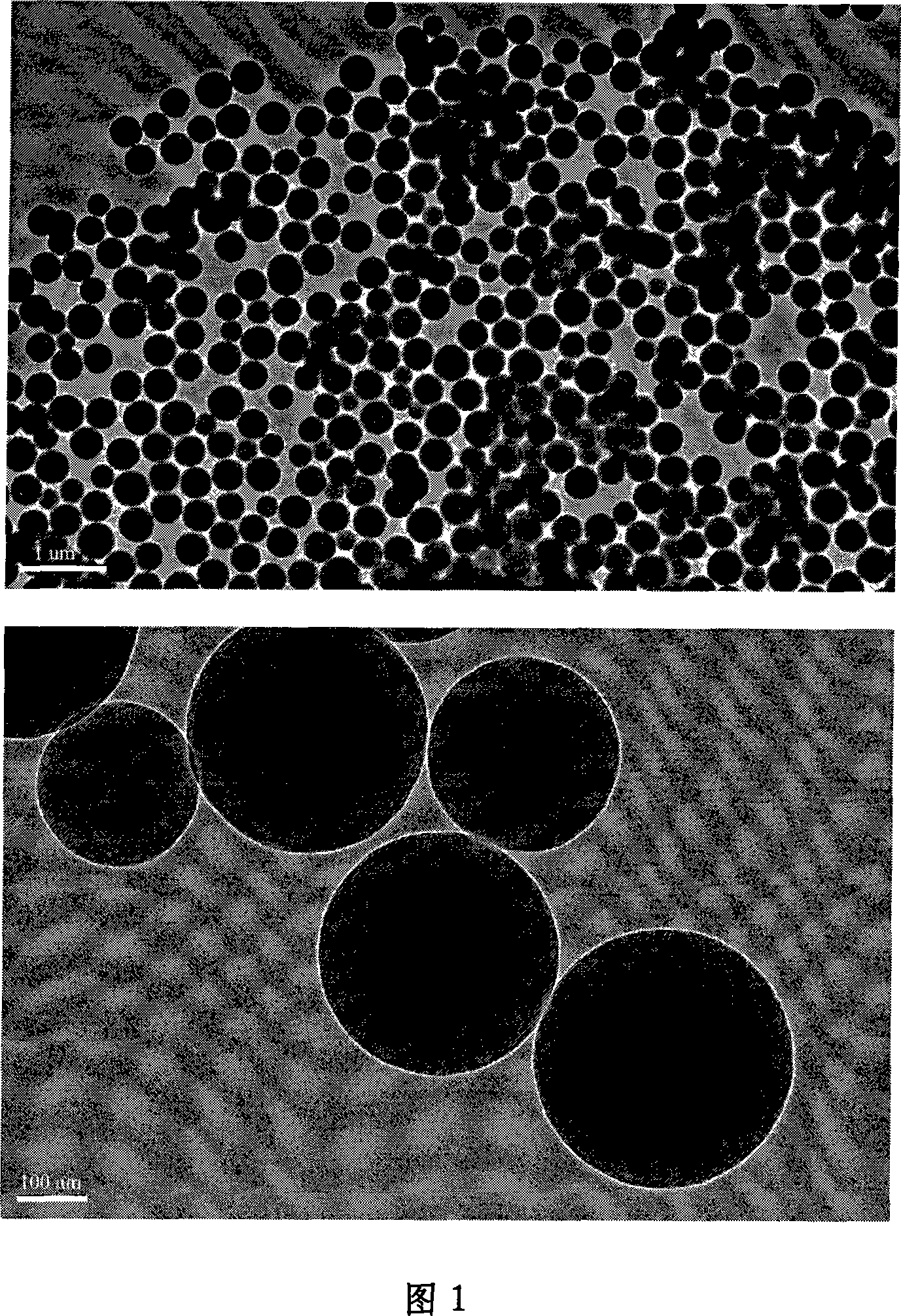

[0032] Weigh 0.1 g of the prepared europium-terephthalic acid complex, put it into a flask filled with 20 ml of absolute ethanol, and disperse it ultrasonically for 25 min; add 2 ml of distilled water and 1.25 ml of 25% ammonia water, and stir magnetically for 30 min; Transfer to a constant temperature water bath at 30°C, add 0.5ml tetraethyl orthosilicate (TEOS) dropwise at a constant speed under magnetic stirring, and end the reaction after stirring for 4 hours; centrifuge the product, wash twice with absolute ethanol and distilled water; dry at 60°C After 4 hours, dry at 80°C for 8 hours to obtain a white powder, which is the product. ...

Embodiment 2

[0035] Add 15ml of ammonium terephthalate solution into a 100ml flask, slowly add 10ml of 0.1M EuCl dropwise under magnetic stirring 3 solution; react in a water bath at 40°C for 4h; centrifuge the product and wash it three times with absolute ethanol; dry at 100°C for 4h to obtain the europium-terephthalic acid rare earth complex.

[0036] Weigh 0.1 g of the prepared europium-terephthalic acid complex, put it into a flask filled with 20 ml of absolute ethanol, and disperse it ultrasonically for 30 min; add 3 ml of distilled water and 2.50 ml of 25% ammonia water, and stir magnetically for 30 min; transfer the flask to In a constant temperature water bath at 40°C, slowly add 3.0ml tetraethyl orthosilicate (TEOS) dropwise at a constant speed under magnetic stirring, and stop the reaction after stirring for 5 hours; centrifuge the product, wash with absolute ethanol and distilled water three times each; dry at 40°C for 6 hours Then dry at 100°C for 4 hours to obtain a white powd...

Embodiment 3

[0038] Add 15ml of ammonium terephthalate solution into a 100ml flask, slowly add 10ml of 0.1M EuCl dropwise under magnetic stirring 3 solution; react in a water bath at 80°C for 2h; centrifuge the product and wash it three times with absolute ethanol; dry at 60°C for 12h to obtain the europium-terephthalic acid rare earth complex.

[0039] Weigh 0.05 g of the prepared europium-terephthalic acid complex, put it into a flask filled with 20 ml of absolute ethanol, and disperse it ultrasonically for 45 min; add 2 ml of distilled water and 1.25 ml of 25% ammonia water, and stir magnetically for 45 min; transfer the flask to In a constant temperature water bath at 25°C, slowly add 0.5ml tetraethyl orthosilicate (TEOS) dropwise at a constant speed under magnetic stirring, and stop the reaction after stirring for 6 hours; centrifuge the product, wash with absolute ethanol and distilled water three times each; dry at 80°C for 2 hours Then dry at 60°C for 12 hours to obtain a white pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com