Rapid automobile sheet metal part edge wrapping mechanism

A technology for automobile sheet metal parts and rapid wrapping, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult control, inability to complete the wrapping of sheet metal parts at one time, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

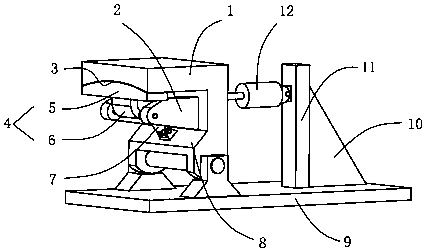

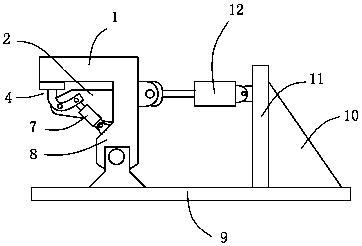

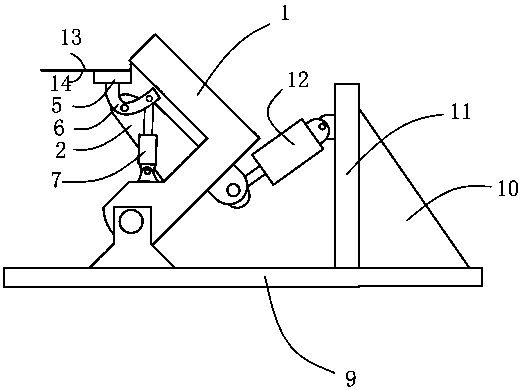

[0025] Example: a rapid hemming mechanism for automobile sheet metal parts (see figure 1 figure 2 ), including a base 9, an upper hemming mold 1 hinged on the base and a lower hemming mold 4 hinged on the upper hemming mold.

[0026] A base 11 perpendicular to the upper surface of the base is fixed on the base, and a triangular base rib 10 is fixed between the base and the upper surface of the base. An upper die driving cylinder 12 is connected between the base and the upper hemming die, and both ends of the upper die driving cylinder are hingedly connected. The upper hemming die is driven and rotated by the upper die driving cylinder, and the rotation angle of the upper hemming die is greater than 90°.

[0027] The upper hemming die is L-shaped, the end of the long side of the L-shape is hinged on the base, the side of the long side is hinged to the upper die driving cylinder, and the short side of the L shape and the upper die driving cylinder are on both sides of the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com