Edge wrapping device suitable for film wrapping and edge wrapping machine

A technology of hemming device and hemming machine, which is applied in the field of mechanical equipment, can solve the problems of slow wrapping speed, high manual error, low efficiency, etc., and achieve the effect of convenient movement, guaranteed contact effect, and wrapping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

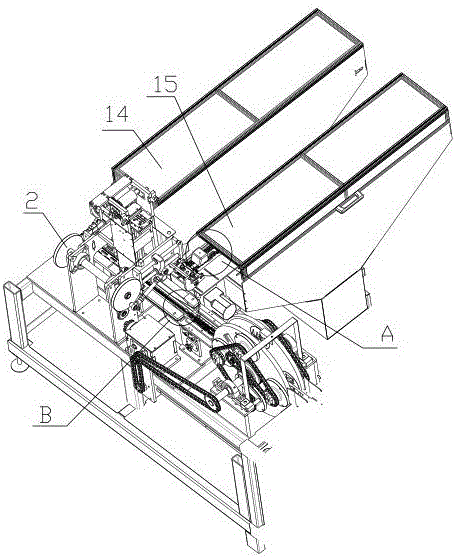

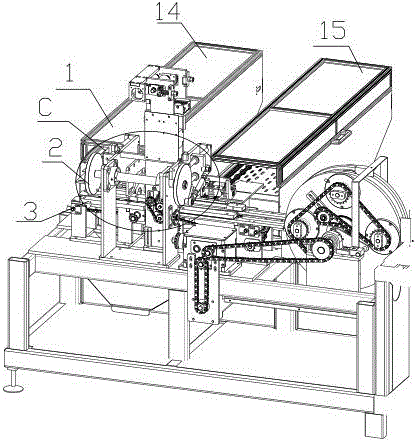

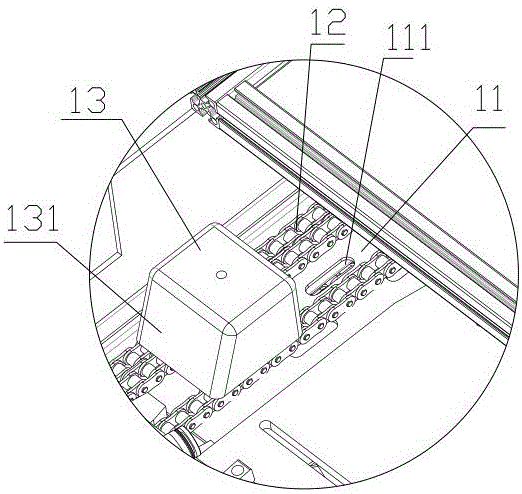

[0036] Example 1, such as figure 1 As shown, a feeding device 1 is provided, and the feeding device 1 includes two parts, namely a positive plate feeding device 14 and a negative plate feeding device 15, which are respectively used to place the positive plate and the negative plate. The specific structure of each feeding device is as follows image 3 As shown, the transmission frame 11 is included, and the powder filter holes 111 are opened on the transmission frame 11, which are used to shake off the lead powder and increase the cleanliness of the equipment and the pole plate. The transmission frame 11 is provided with a chain 12, and the chain 12 is driven by a driving member such as a sprocket wheel to move. And a plurality of pole plates are all stacked and this is placed on the chain 12, is driven forward. Preferably, the chain 12 is a metal chain, on which a pressing block 13 is placed. The bottom of the pressing block 13 is magnetic, and can be easily adsorbed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com