Bending and angle wrapping die and bending and angle wrapping method

A mold and corner wrapping technology, applied in the field of bending wrapping die and corner wrapping, can solve the problems of hidden danger of manipulator, complicated structure of sliding block, complicated structure of door shell, etc., so as to reduce production cost and be suitable for popularization and use. , the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

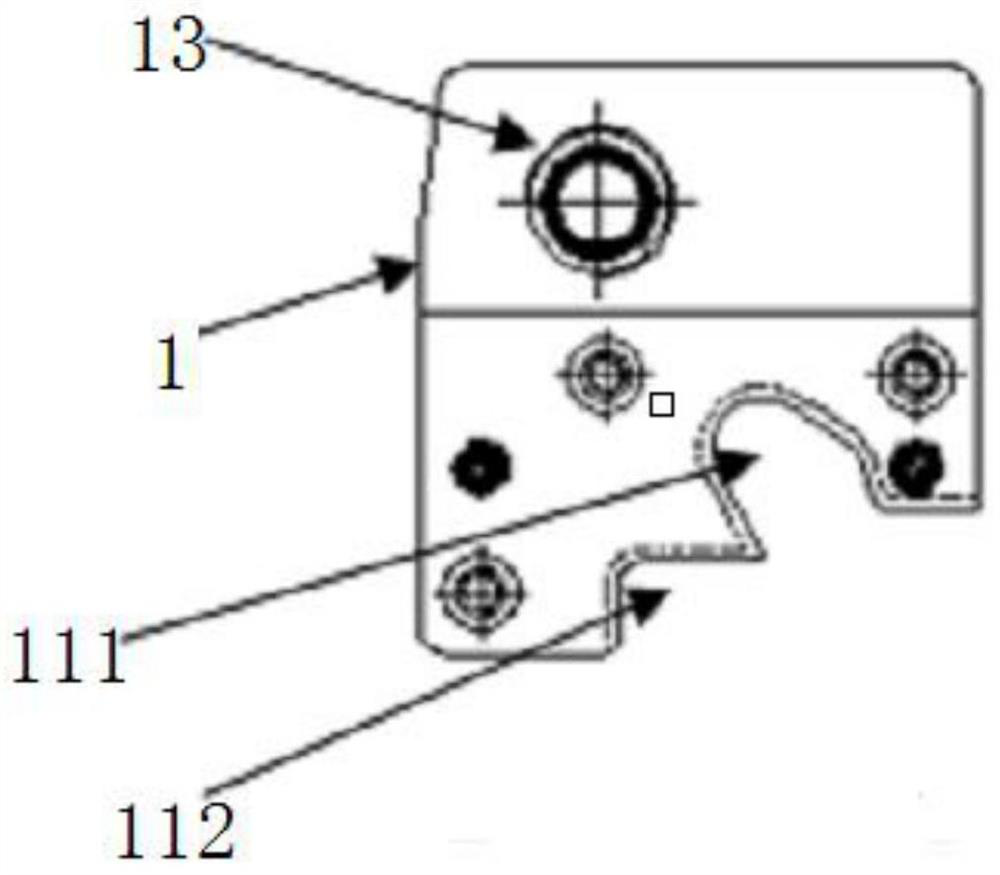

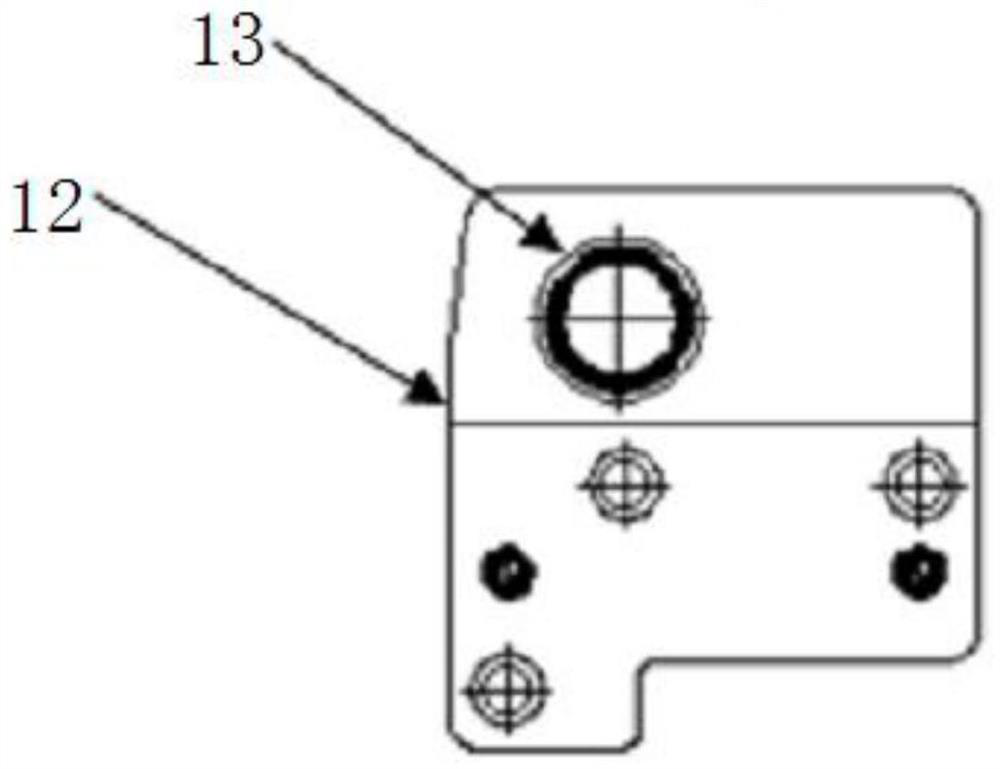

[0043] Such as Figure 1-5 As shown, the present invention introduces a kind of bending corner wrapping mold, which includes a first mold 2 and a second mold 3 which are arranged oppositely. The first mold 2 is equipped with a corner wrapping knife 1 towards the side of the second mold 3, and the corner wrapping knife 1 is rotatably connected with the first mold 2 through the first fixed shaft 13. Through the above settings, the plate is wrapped in the form of rotating angle wrapping, thereby reducing the contact area between the mold and the plate, reducing the friction between the mold and the plate, and avoiding the corner wrapping caused by the excessive friction between the plate and the mold The problem of paint peeling and film breaking. The side of the first mold 2 facing the second mold 3 is also equipped with a corner-wrapping knife fixing seat 24 , and a corner-wrapping knife fixing seat 24 is provided with a mounting hole matched with the first fixed shaft 13 . T...

Embodiment 2

[0053] Based on the corner-wrapping mold provided in the first embodiment of the present application, the second embodiment of the present application proposes another corner-wrapping knife 1 . The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0054] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

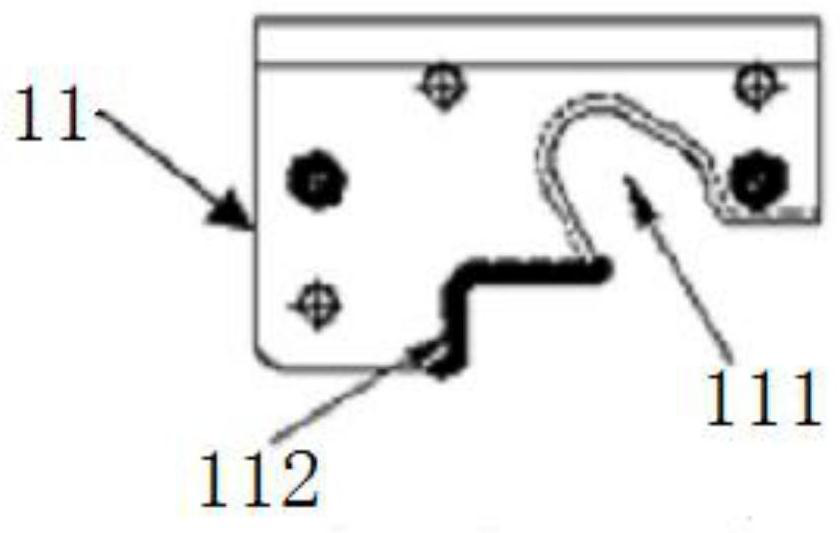

[0055] A corner-wrapping mold disclosed in this embodiment includes a corner-wrapping knife 1. The corner-wrapping knife 1 includes a corner-wrapping knife main body 11 and a corner-wrapping knife fixing seat 12. A first fixed shaft is arranged on the corner-wrapping knife fixing seat 12. 13 is rotatably connected with the first mold 2, and the angle-wrapping knife fixing seat 12 is connected with the first mold 2 only by one fixed shaft, so that the...

Embodiment 3

[0060] This embodiment discloses a method for bending and wrapping a corner-wrapping mold. A bending knife 25 is installed on the side of the first mold 2 facing the second mold 3, and the bending knife 25 is located on the side of the corner-wrapping knife 1. Before the corner wrapping program is carried out, the bending knife 25 first bends the plate. The concrete bending angle wrapping method in this implementation includes the following steps:

[0061] 1) The mold starts to run, and the first mold 2 and the second mold 3 are reset;

[0062] 2) The first mold 2 descends, the first stripping plate 21 provided on the first mold 2 presses the plate, the first mold 2 continues to descend, and the bending knife 25 provided on the first mold 2 begins to perform the bending procedure on the plate;

[0063] 3) The bending procedure is completed, the first mold 2 continues to descend, the limit shaft 211 set on the first stripping plate 21 enters the guide groove 111 set on the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com