Patents

Literature

34results about How to "Lower flow temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

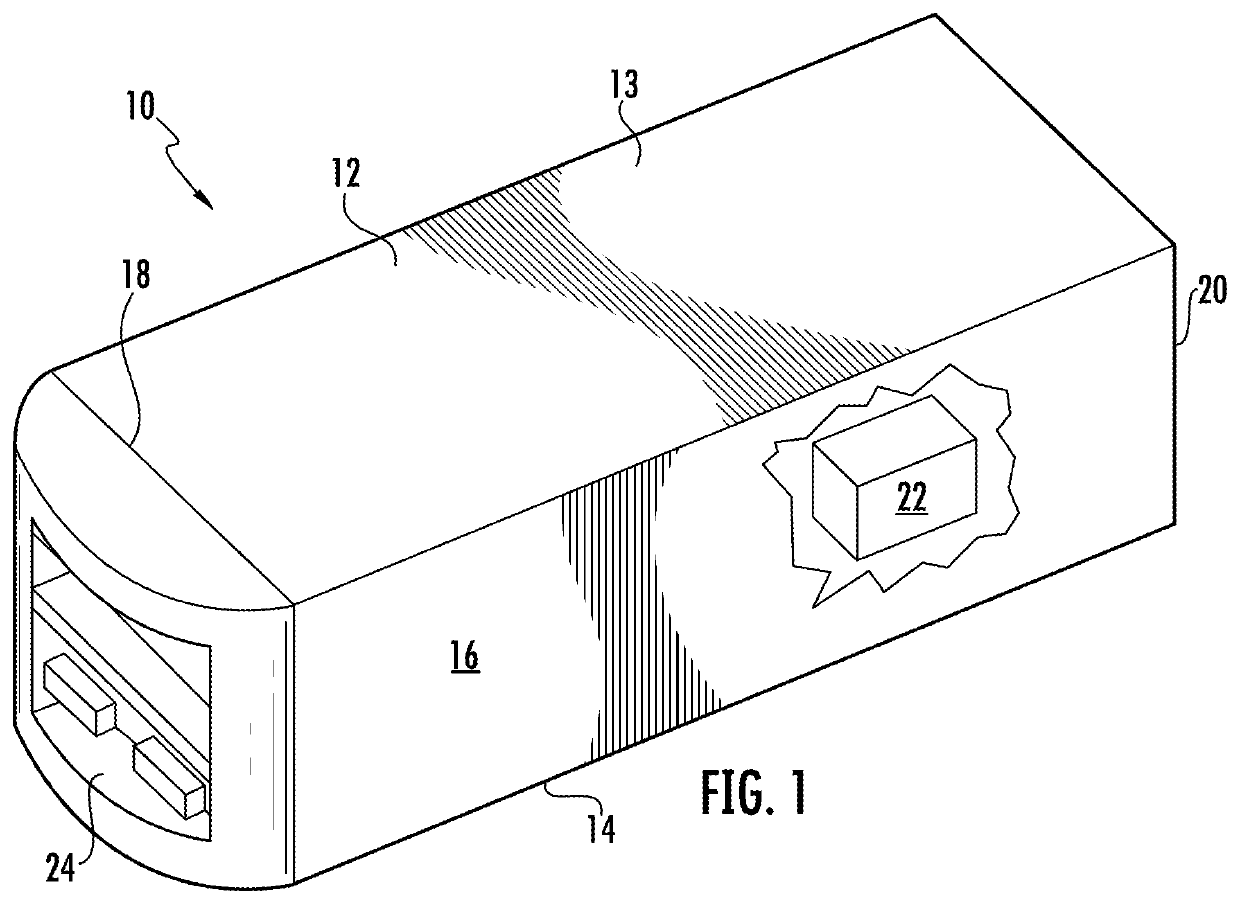

Water Condenser

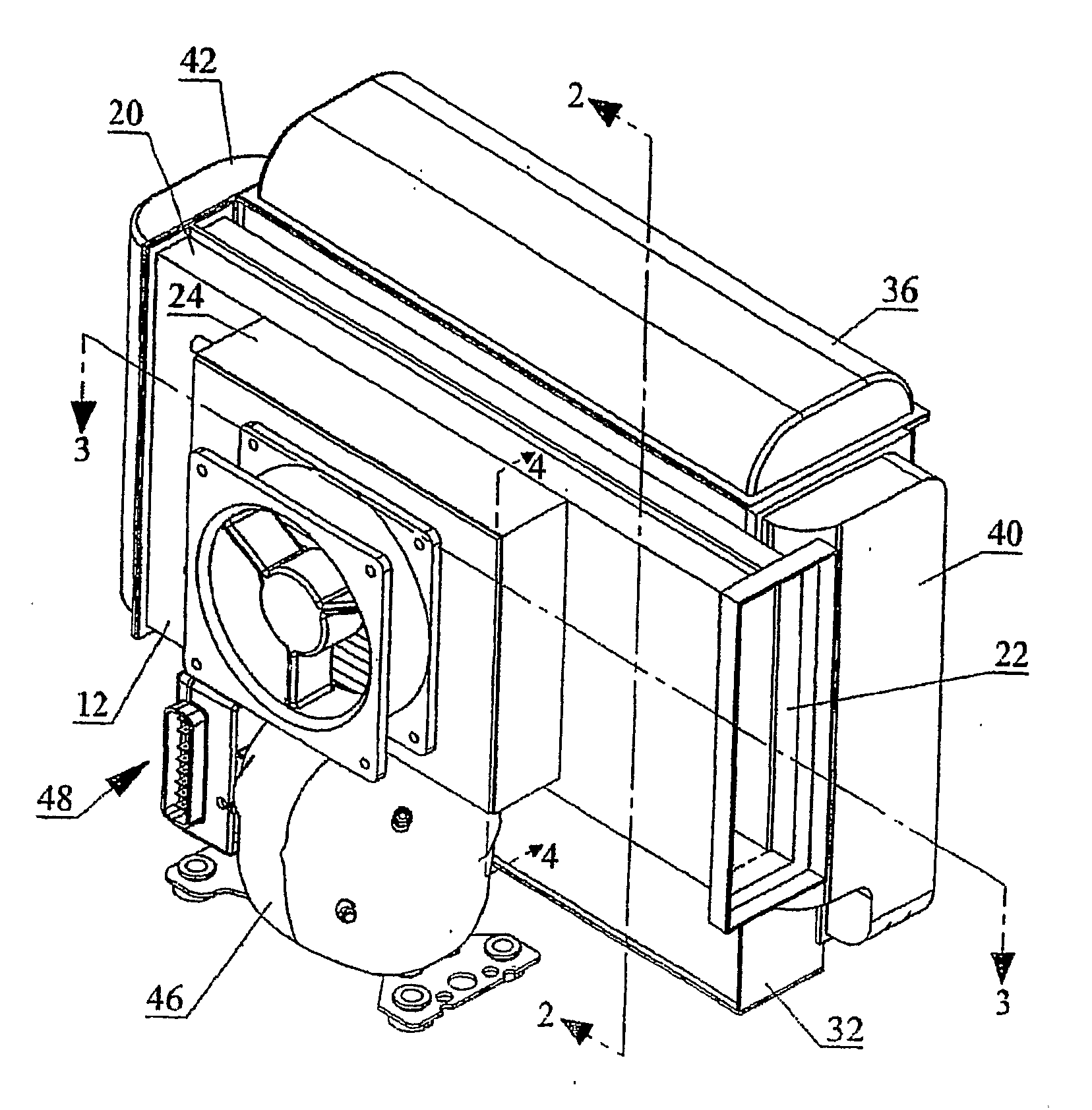

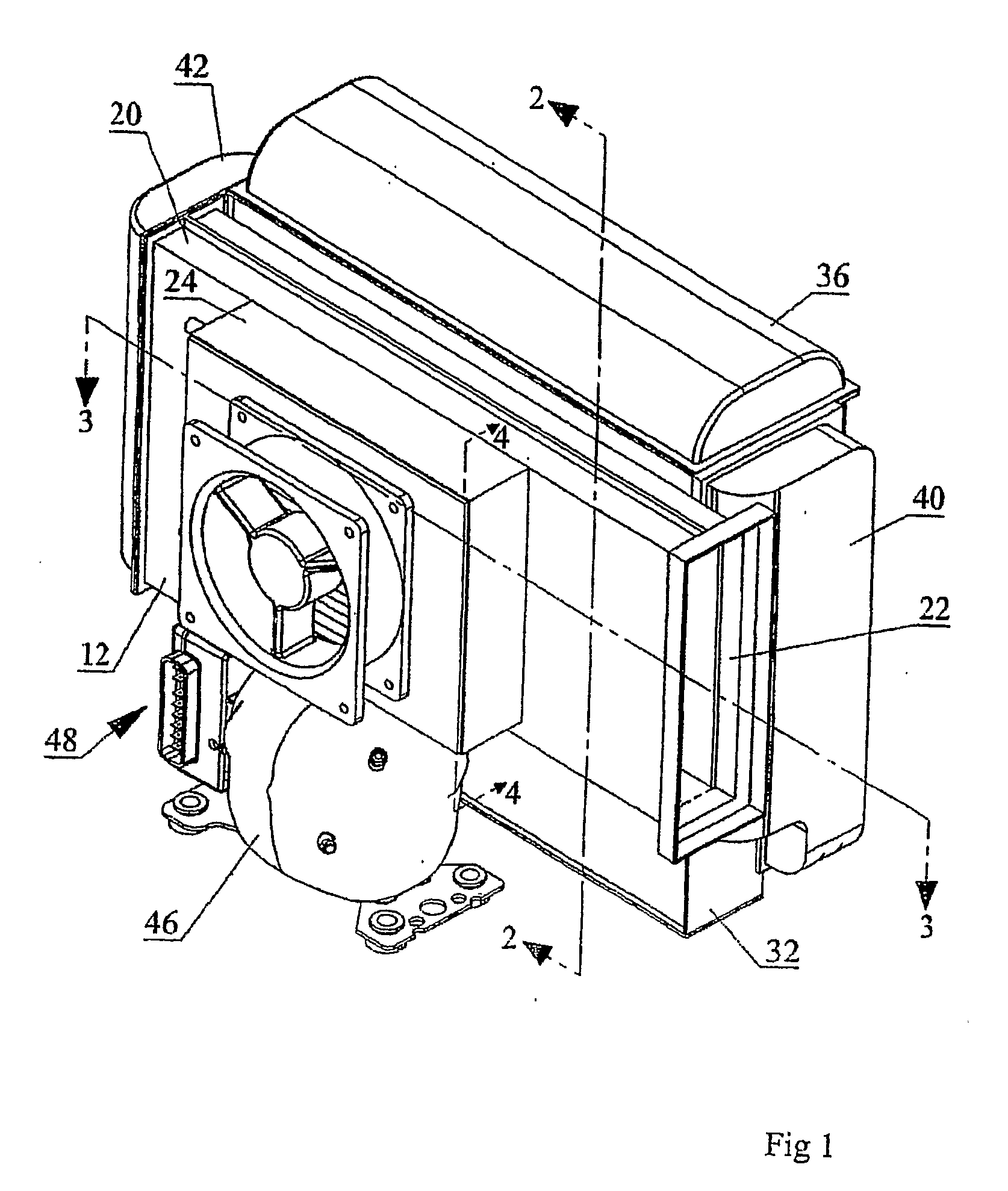

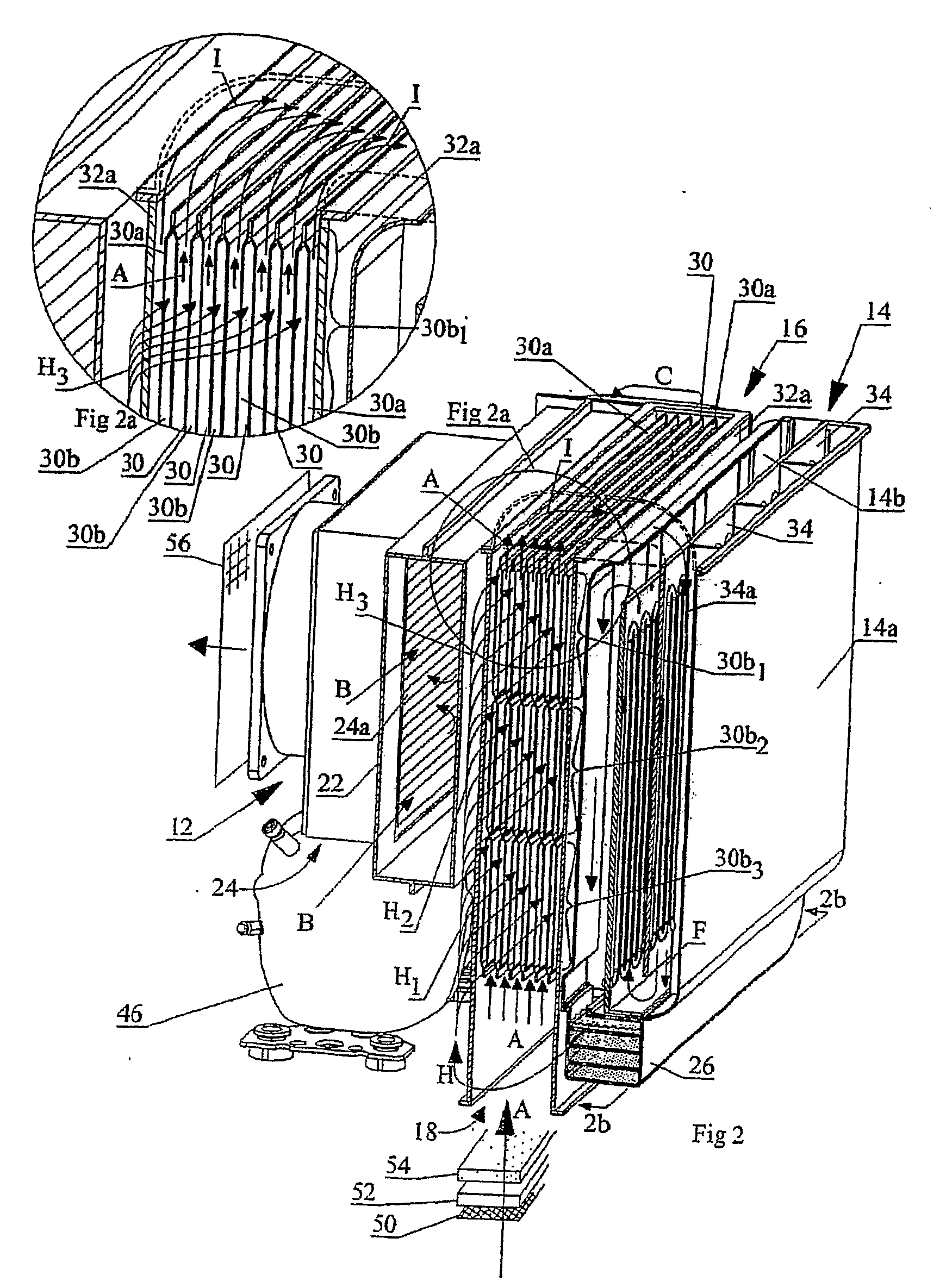

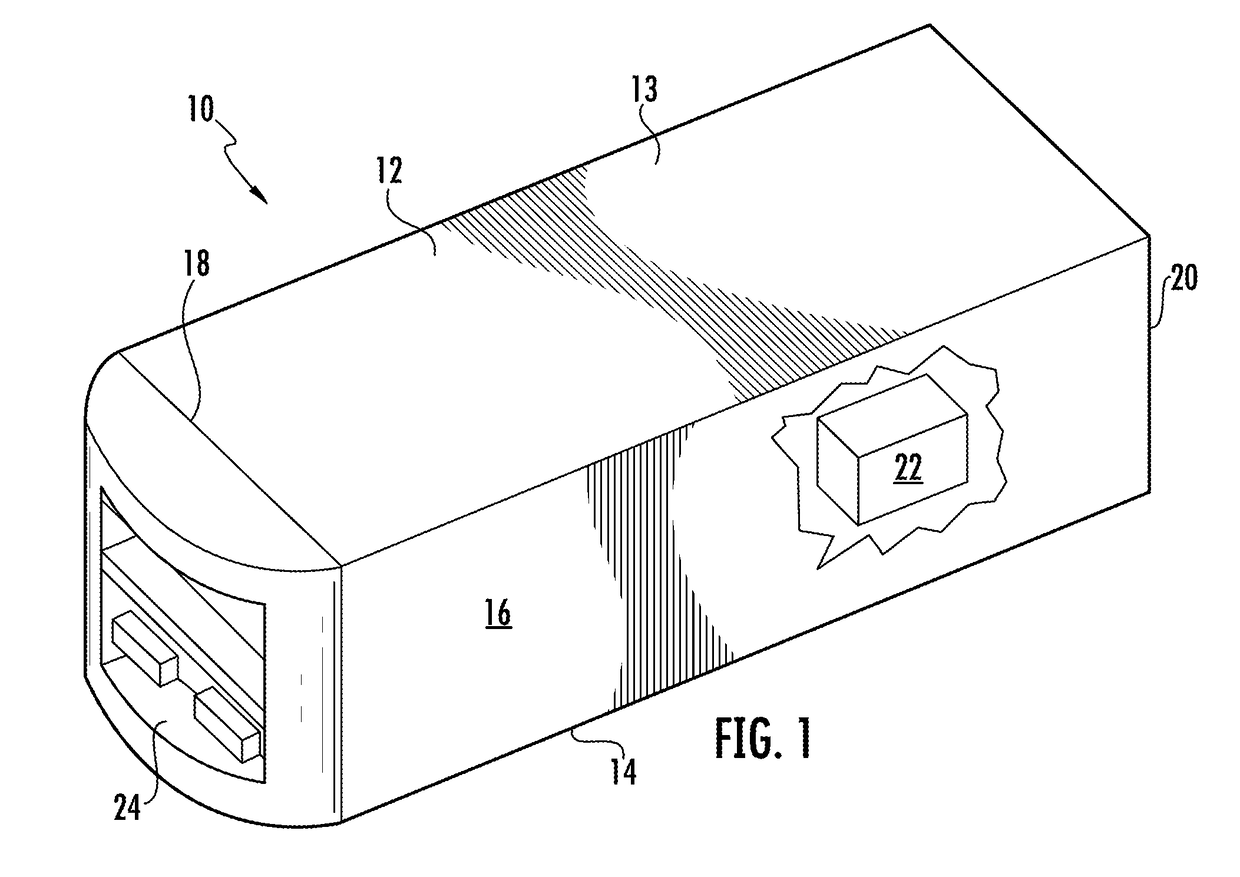

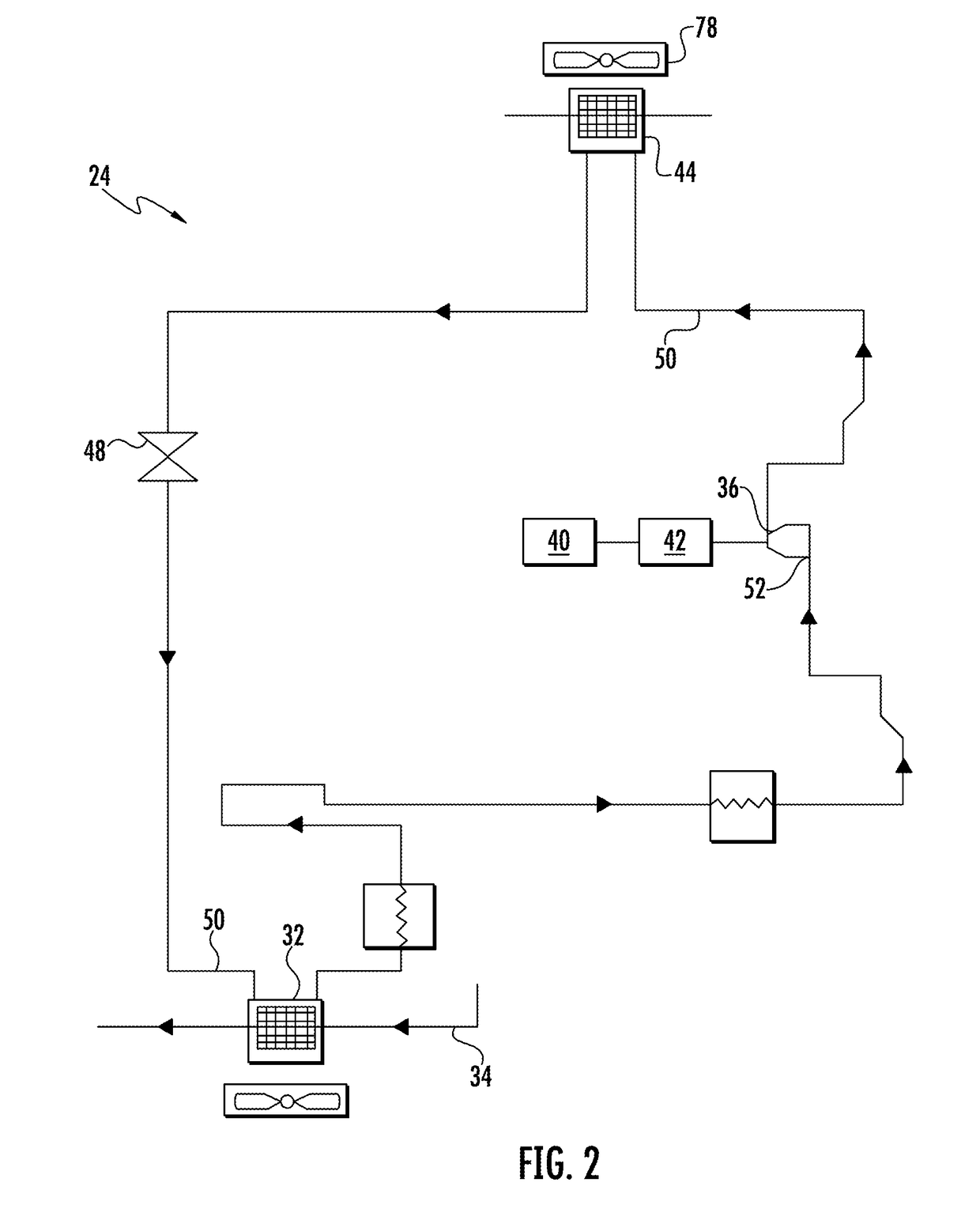

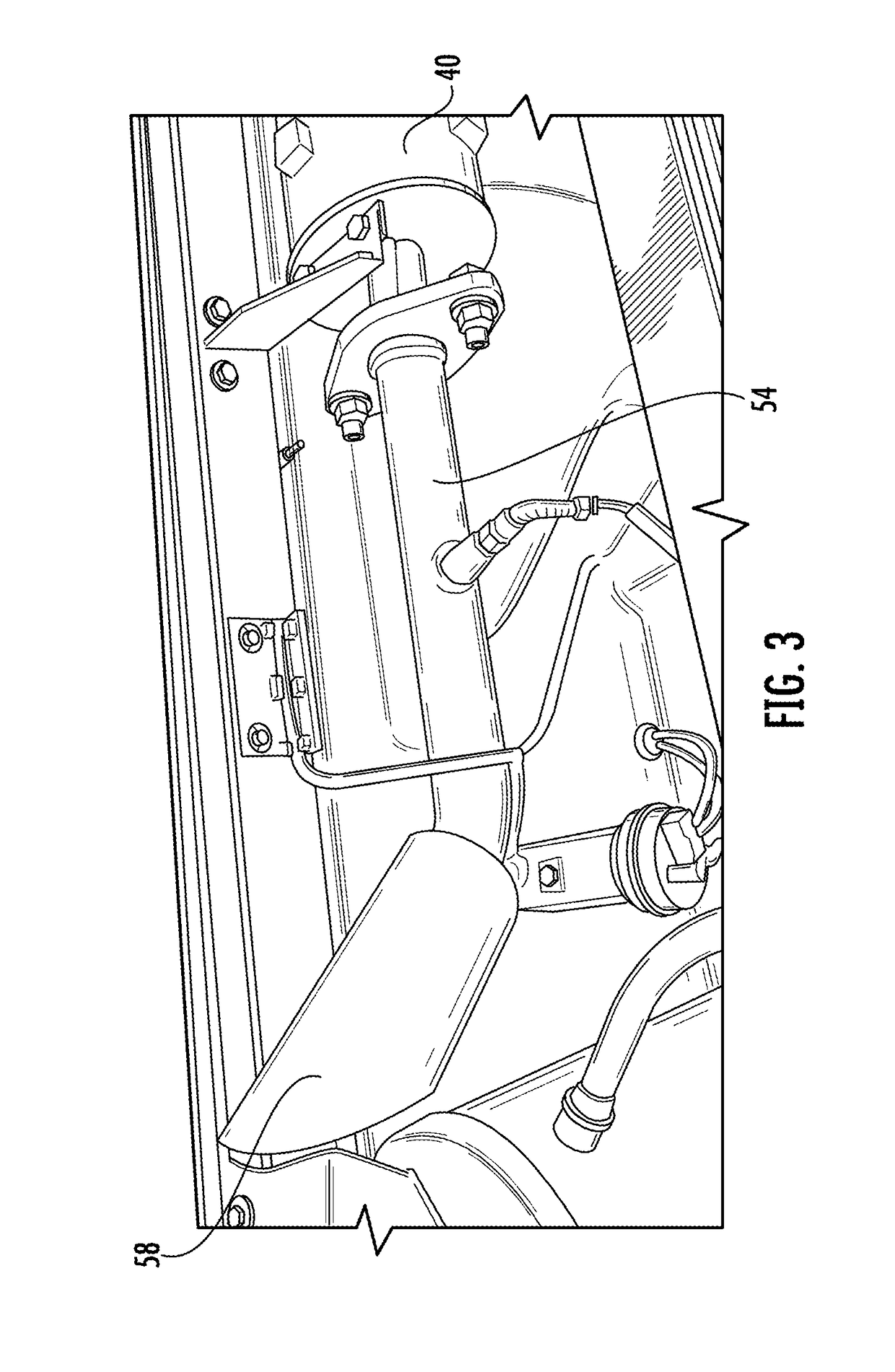

InactiveUS20080314062A1Reduce temperatureIncrease air flow rateWater/sewage treatment by irradiationEvaporators/condensersRefrigerantEvaporator

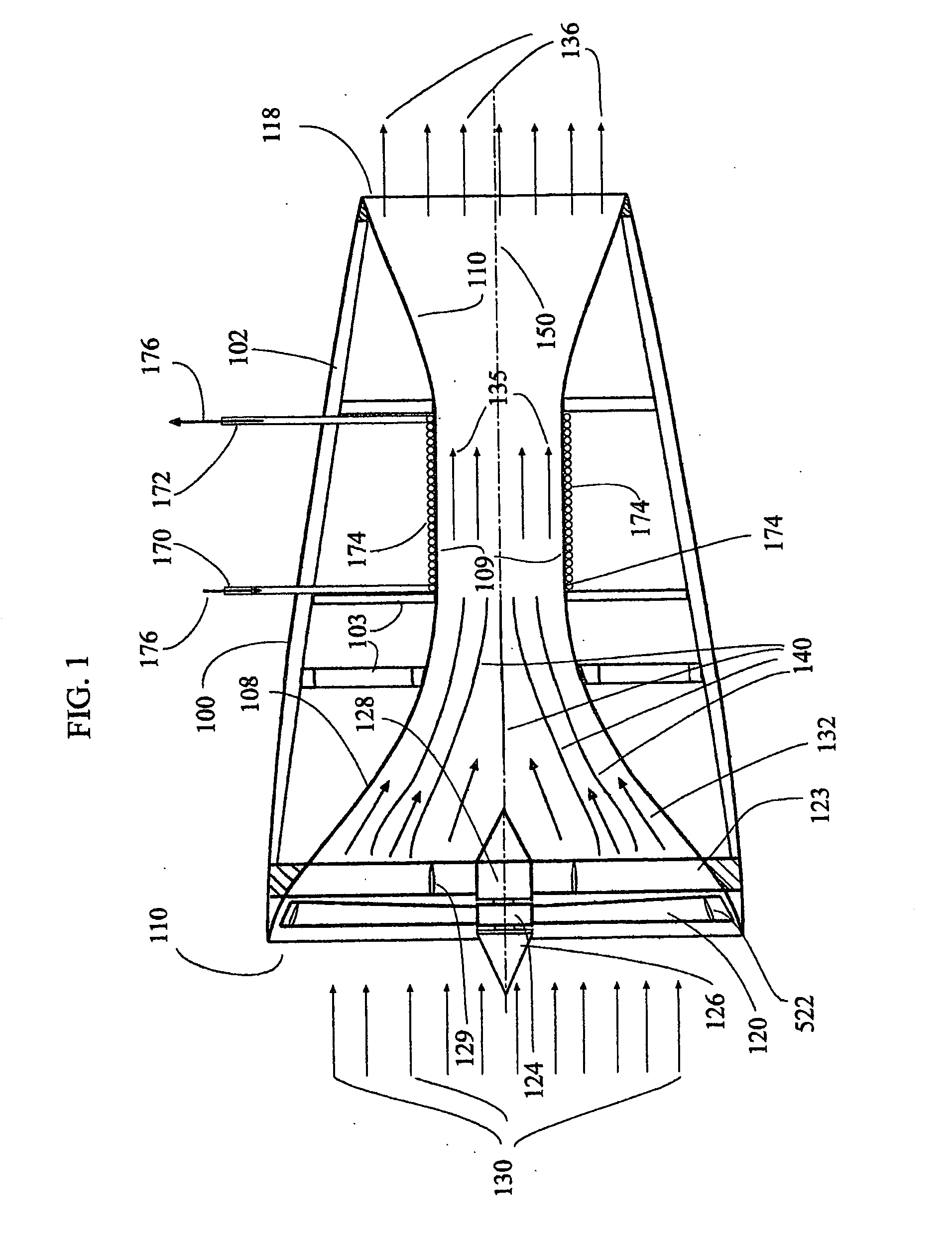

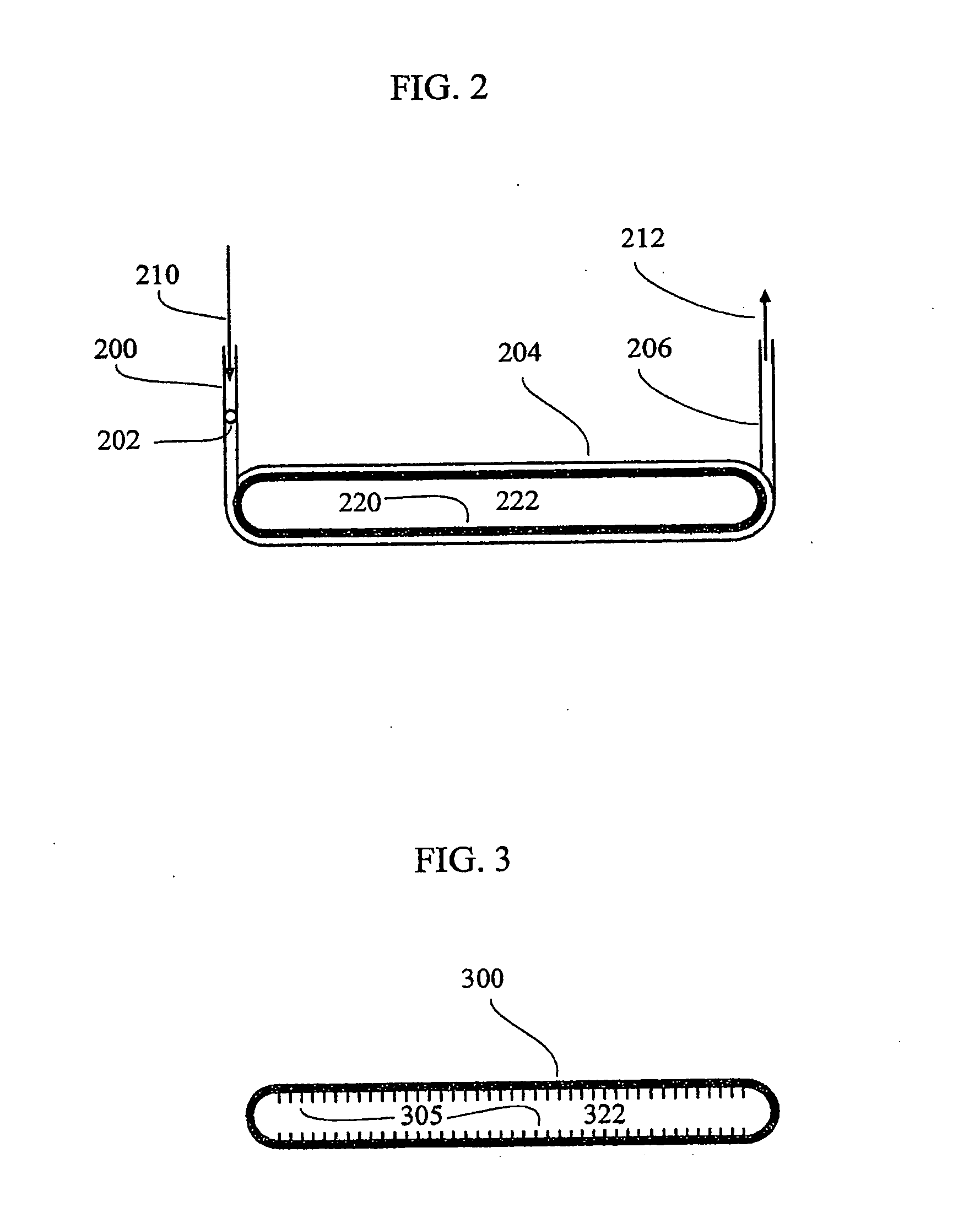

A water condenser includes a fan which draws a primary airflow through an upstream refrigerant evaporator, through an air-to-air heat exchanger and in one embodiment also an air-to-water heat exchanger uses cold water collected as condensate from the evaporator, the airflow to the evaporator being pre-cooled by passing through the air-to-air heat exchanger and the air-to-water heat exchanger prior to entry into the evaporator wherein the airflow is further cooled to below its dew point so as to condense moisture onto the evaporator far gravity collection. The evaporator is cooled by a closed refrigerant circuit. The refrigerant condenser for the closed refrigerant circuit may employ the fan drawing the airflow through the evaporator or a separate fan, both of which drawing an auxiliary airflow separate from the airflow through the evaporator through a manifold whereby bath the auxiliary airflow and the airflow through the evaporator, or just the auxiliary airflow are guided through the condenser and corresponding fan.

Owner:FREEDOM WATER CO LTD

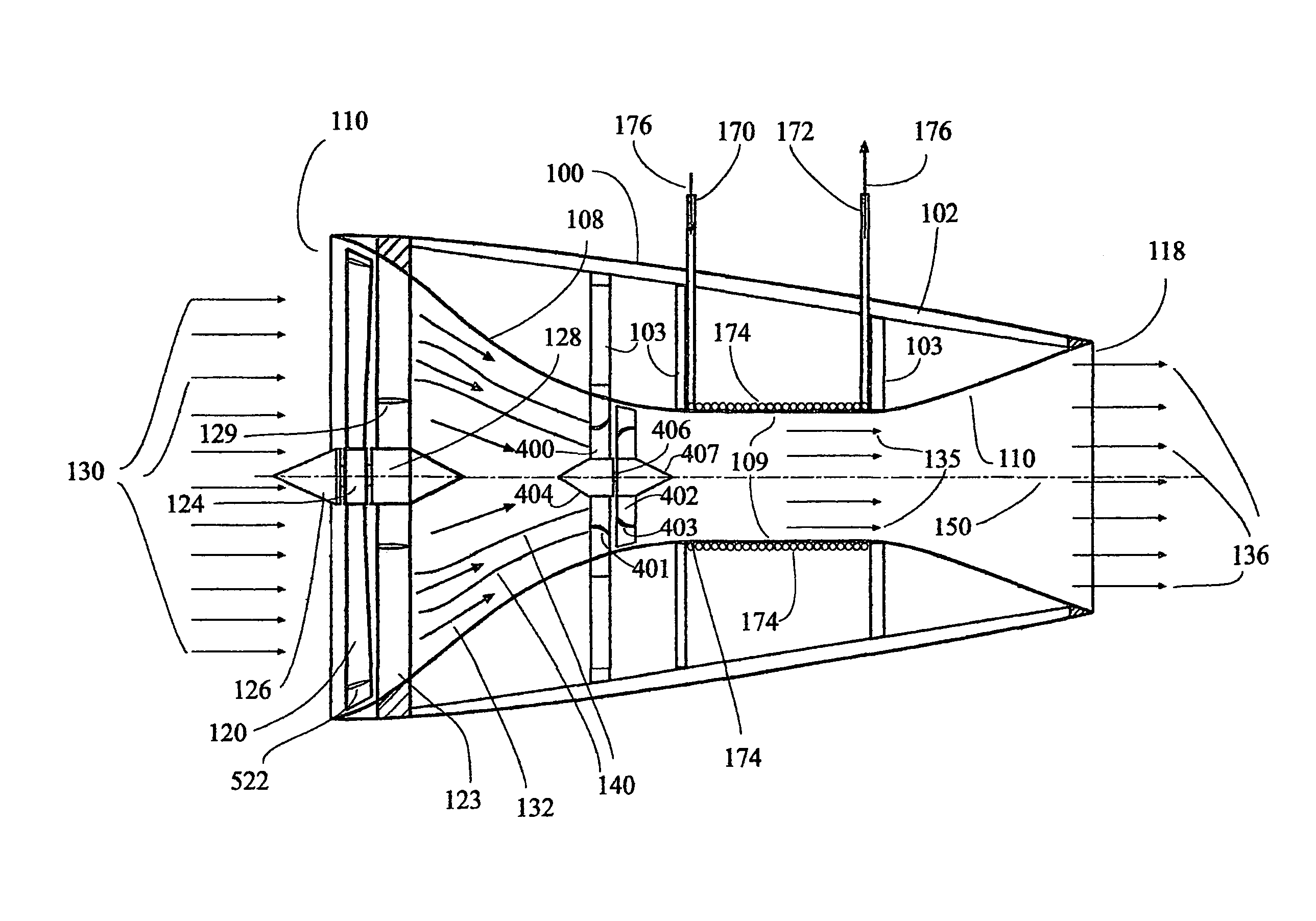

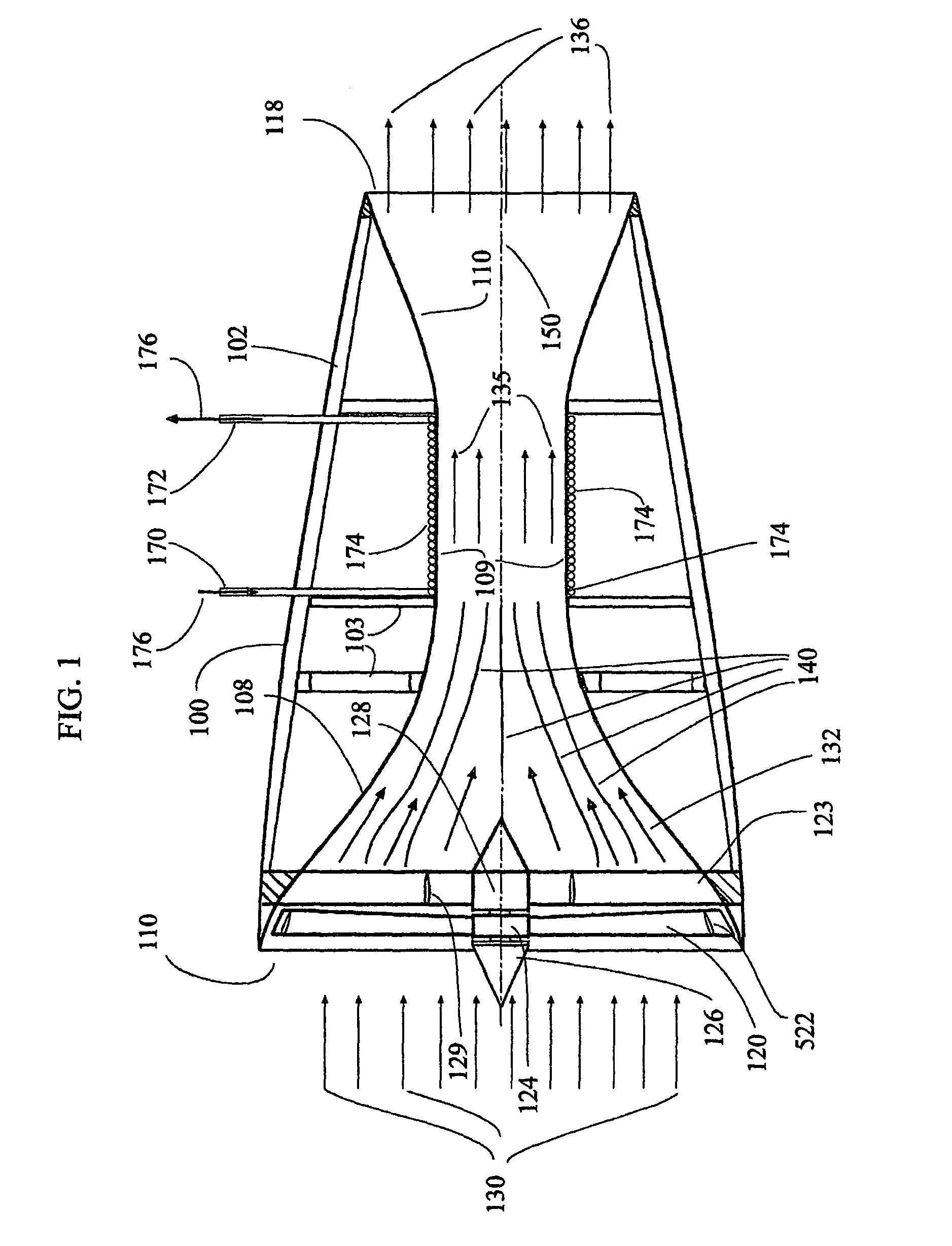

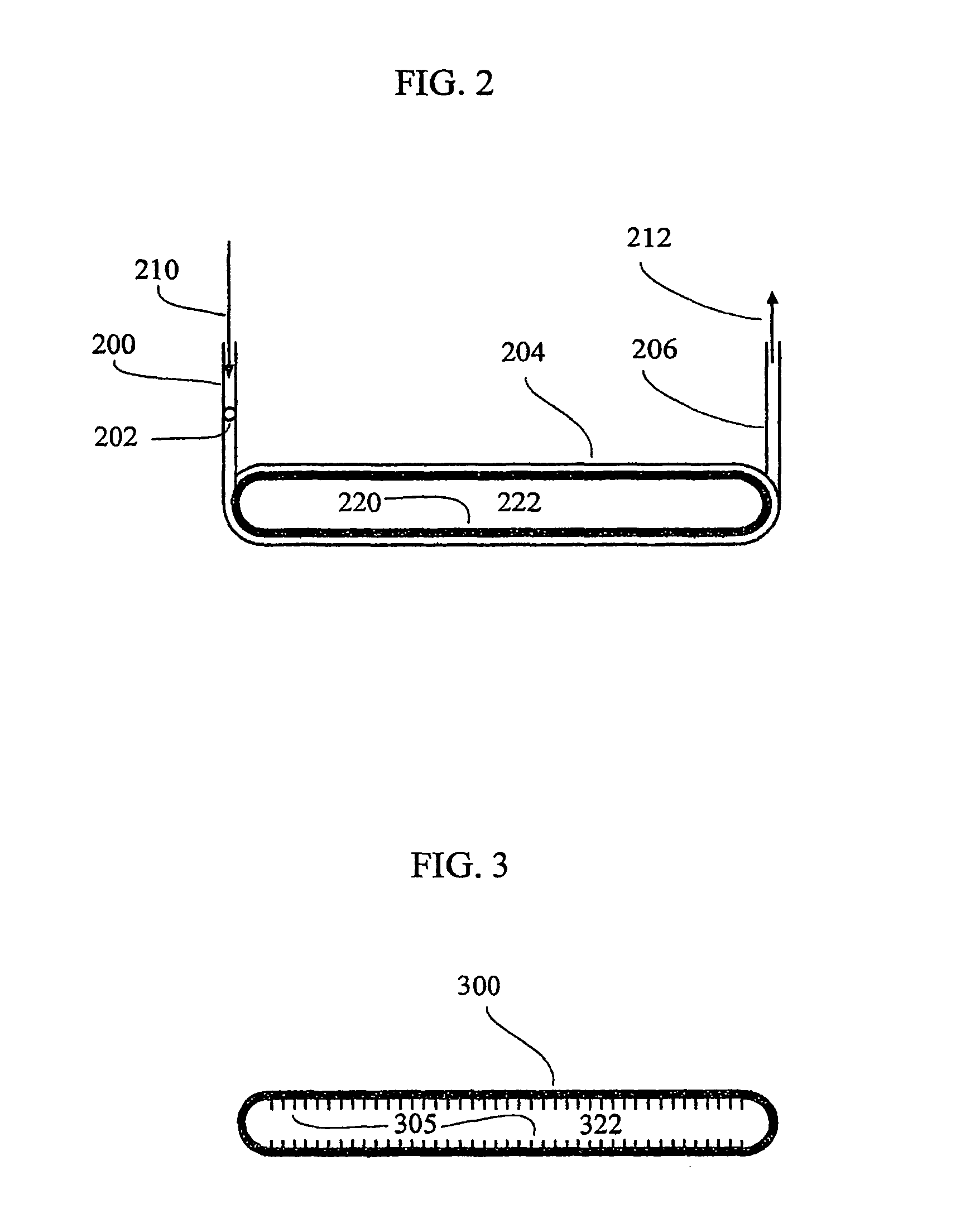

A method for cooling air and devices

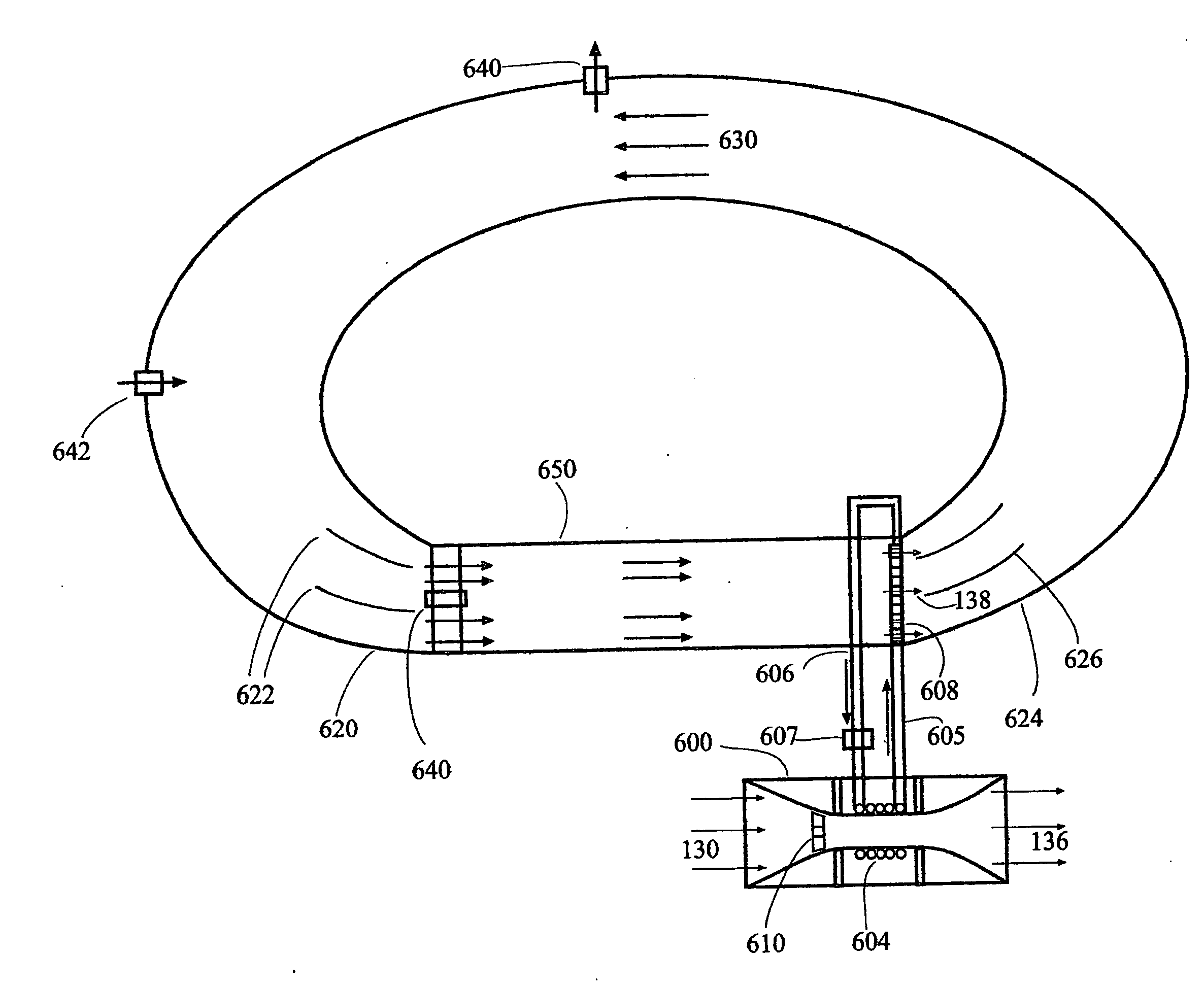

ActiveUS20100162685A1Avoid accumulationLower flow temperatureSemiconductor/solid-state device detailsCompression machinesElectricityCold air

A method of constructing self-powered air-conditioner comprises a convergent divergent nozzle where powered fan pushes air into said nozzle. While the pushed air accelerates toward the nozzle throat it becomes colder as air internal energy transformed into kinetic energy. An axial turbine installed within the nozzle throat extracts energy from the air in the nozzle and drives an electrical generator that provides electricity to the fan electric motor. Alternatively the turbine and fan are installed on common shaft, which could be the electric generator shaft. The cold air within the nozzle throat cools the nozzle throat skin, which serves as air-conditioner core. The cold nozzle skin is wrapped with coiled pipes in which liquid flows, becomes colder and this cold liquid flows away to heat exchanger where air is flowing through it and becomes colder. This cold air is then flows into spaces needed to be air-conditioned.

Owner:HIRSHBERG ISRAEL

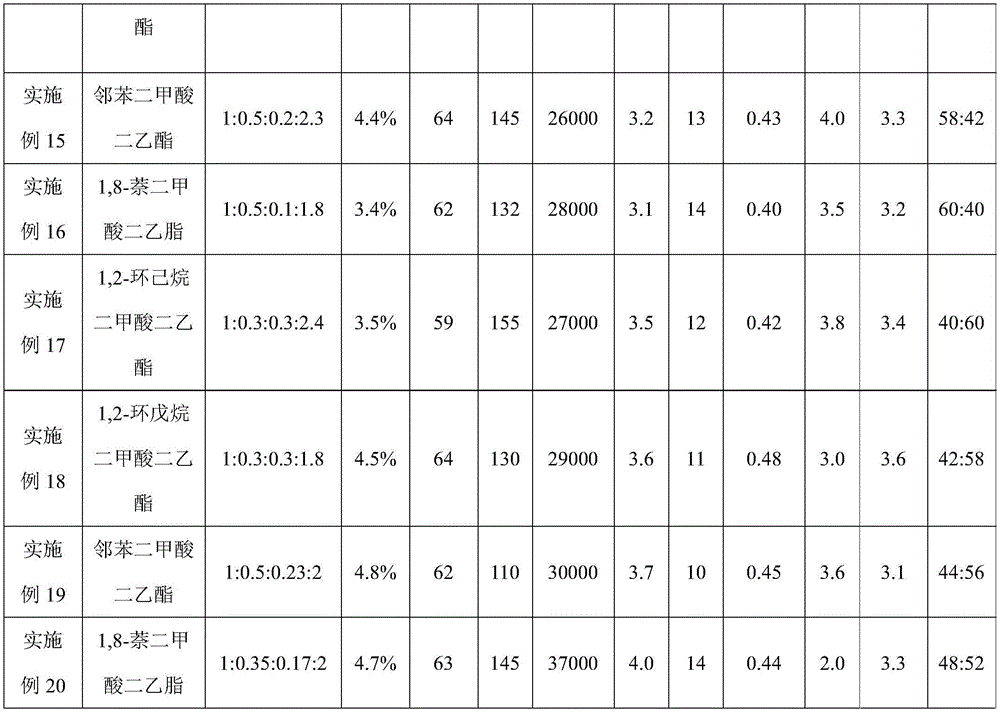

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Anti-static two-sided gold-stamped, printed and embossed PVC (polyvinyl chloride) sheet and preparation method thereof

InactiveCN104558963AImprove embossing effectImprove antistatic performancePlasticizerPolyvinyl chloride

The invention relates to the technical field of sheets, in particular to an anti-static two-sided gold-stamped, printed and embossed PVC (polyvinyl chloride) sheet and a preparation method thereof. The sheet comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 32-52 parts of a plasticizer, 6-10 parts of a lubricant, 1-4 parts of a heat stabilizer, 0.03-0.07 parts of a slipping agent, 0.03-0.07 parts of pigment powder and 0.1-0.5 parts of calcium powder, wherein the calcium powder is a mixture of nano calcium carbonate and heavy calcium carbonate in the weight ratio of 1:(1.5-2.5), the particle size of the nano calcium carbonate is in a range of 120-150 nm, and the particle size of the heavy calcium carbonate is in a range of 1-10 [mu]m. The raw materials are adopted, and the weight ratio of the raw materials is strictly controlled, so that the sheet is good in anti-static effect, heat-resistant, cold-resistant, acid-resistant, alkali-resistant, heavy-load-resistant, anti-aging, smooth in surface, free of cracks and bubbles, uniform in color, strong in stereoscopic impression, soft in texture, comfortable, healthy and environment-friendly.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

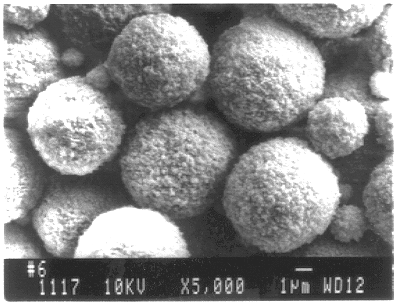

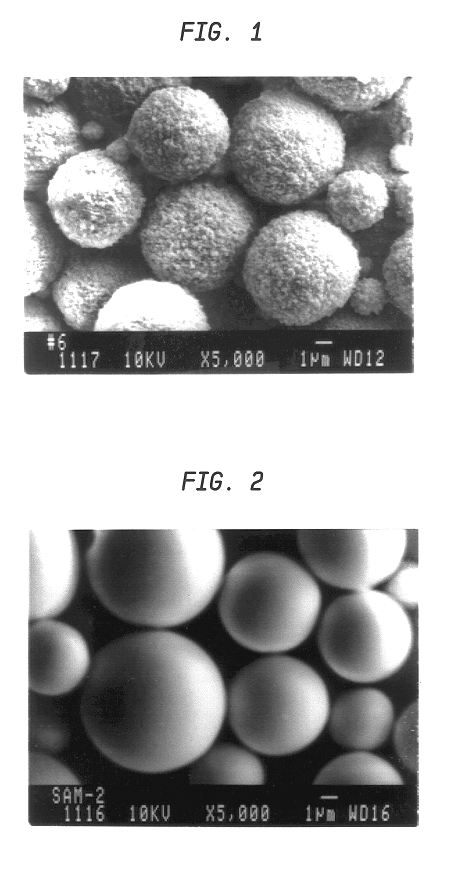

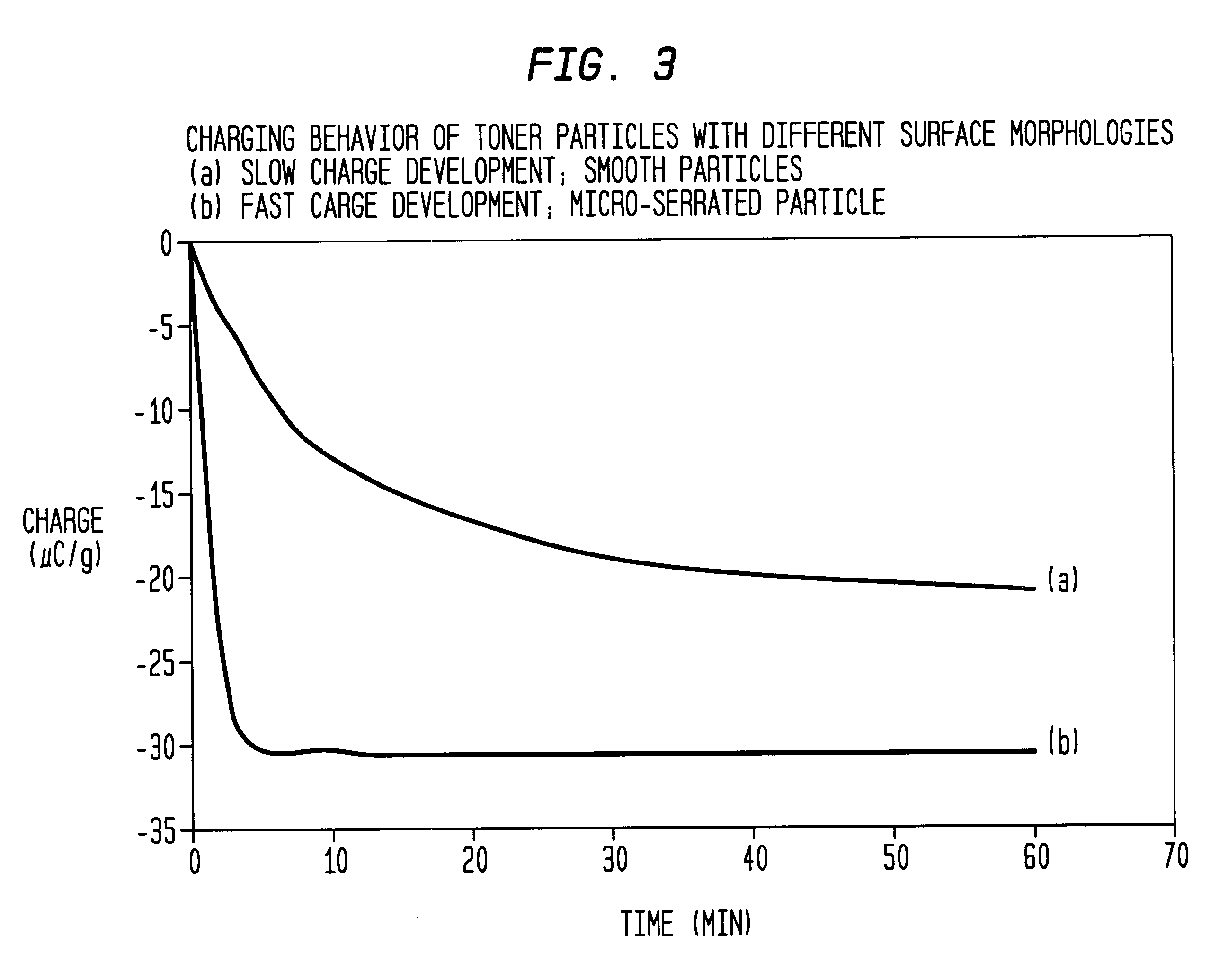

Micro-serrated color toner particles and method of making same

InactiveUS6461783B1Reduce melt viscosityImprove flow characteristicsDevelopersParticulatesPlasticizer

A particulate toner composition is provided with toner resin particles containing a resin component, a colorant component, and optionally a charge control agent characterized in that the toner resin particles have a micro-serrated surface exhibiting a surface roughness index of greater than about 1.2. The novel toner particles are produced by employing a vaporizable plasticizer which is flashed off during processing.

Owner:DPI SOLUTIONS INC

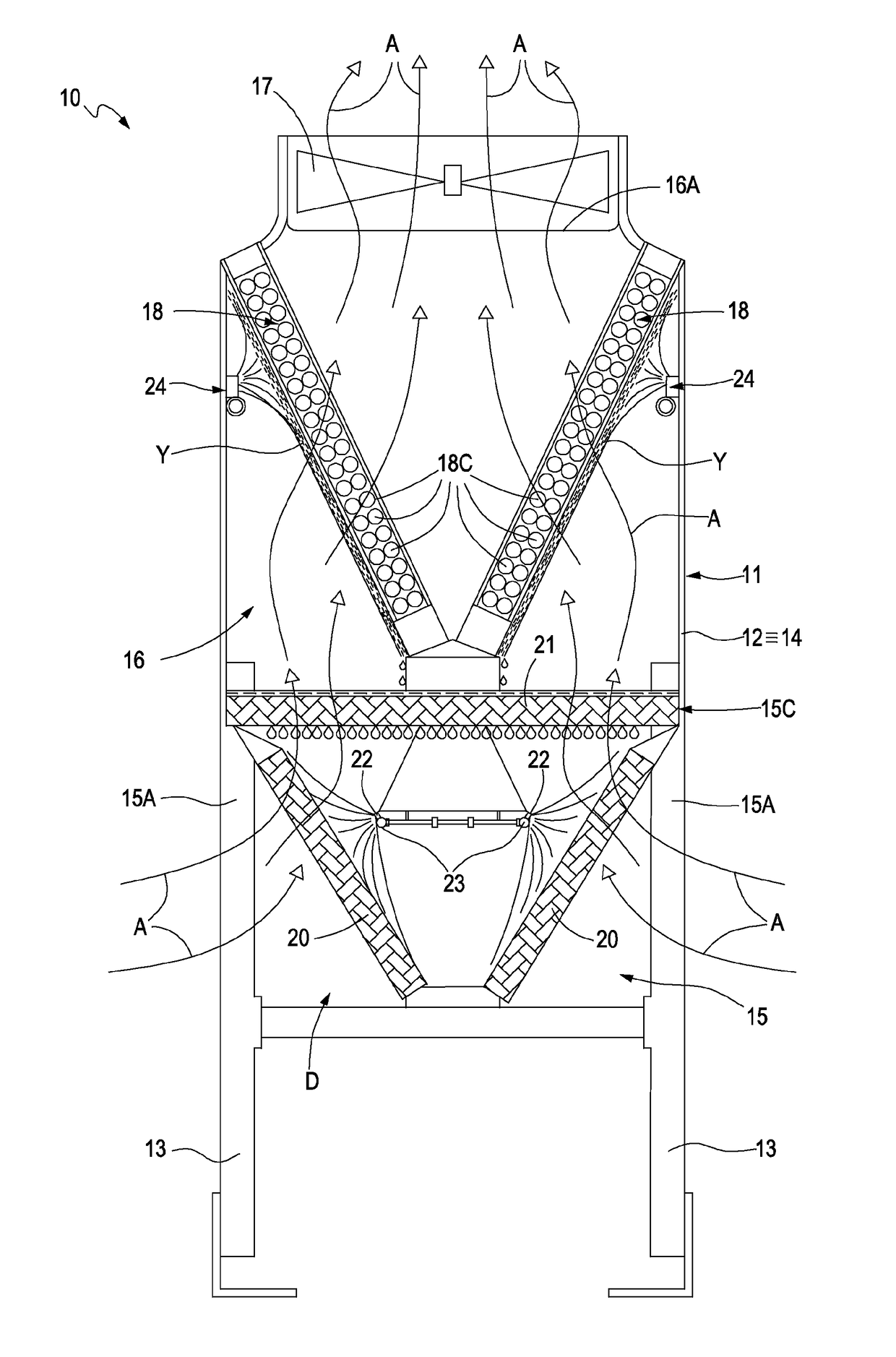

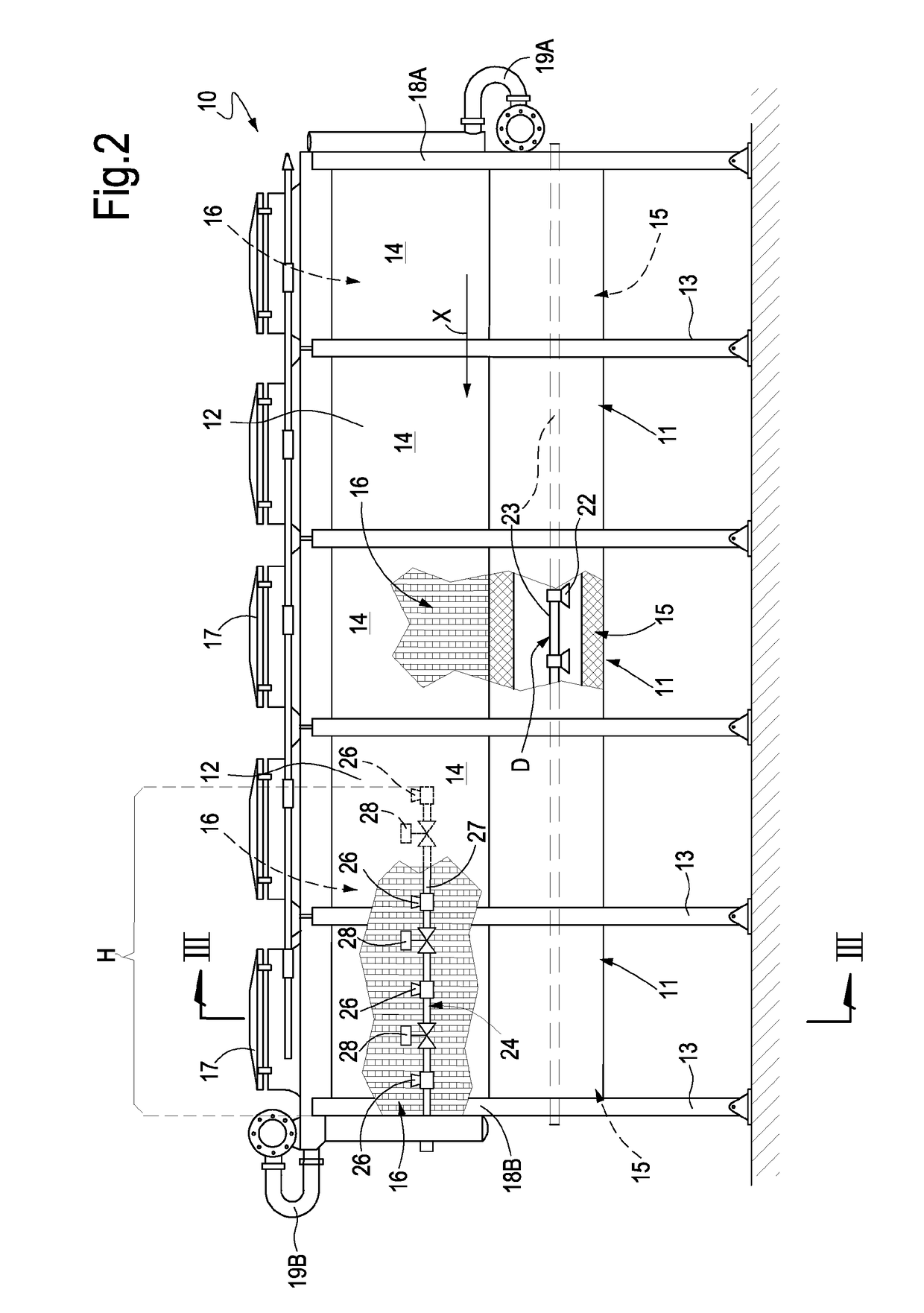

Combined convector

ActiveUS20170082370A1High yieldReduce consumptionCorrosion preventionStationary conduit assembliesEngineeringWetting

A convector for air cooling of a fluid flowing in a pipe, comprising: a path for a cooling air flow comprising an inlet from and an outlet towards the environment, a heat exchange section comprising at least one tube bundle defining a heat exchange surface, said section being provided in said path for the air flow, fan means producing said air flow along said path, so that said air flow externally invests said tube bundle on said; heat exchange surface, a humidifying section arranged in said path, upstream of said heat exchange section, where water is atomized to be invested by the air flow, characterized by comprising a wetting device for wetting directly with water a portion of the heat exchange surface of said tube bundle to further cool said portion of tube bundle.

Owner:FRIGEL FIRENZE SPA

Anti-aging transfer georgette type PVC (Polyvinyl Chloride) sheet and preparation method thereof

InactiveCN104479252AGood anti-aging performanceStrong absorption capacityDecorative surface effectsFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of sheets, and particularly relates to an anti-aging transfer georgette type PVC (Polyvinyl Chloride) sheet and a preparation method thereof. The sheet is prepared from the following raw materials in parts by weight: 50 to 90 parts of PVC resin, 20 to 34 parts of a plasticizer, 8 to 12 parts of a lubricant, 1 to 3 parts of a heat stabilizer, 0.05 to 0.15 part of a slipping agent, 0.02 to 0.04 part of pigment powder, and 0.1 to 0.2 part of an anti-ultraviolet agent, wherein the anti-ultraviolet agent is prepared from one or a mixture of 4-benzoyloxy-2, 2, 6, 6-tetramethylpiperidine and 2-hydroxy-4-octyloxybenzophenone in proportion. According to the sheet, the raw materials are adopted, and the weight ratio of the raw materials are strictly controlled, so that the sheet has a good anti-aging effect, and is resistant to heat, cold, acid, alkali and great pressure, antistatic, smooth in surface, free of crack and bubble, uniform in color and luster, high in stereoscopic impression, soft, comfortable to touch, healthy and environmentally friendly.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Underfill composition

ActiveCN110358483AImprove resin fluidityLower flow temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesFlexural strengthInorganic filler

The invention discloses an underfill composition. The underfill composition comprises 30-65 wt% of a filler, 15-55 wt% of an epoxy resin, 7-20 wt% of a curing agent, 0.1-2.0 wt% of a silane coupling agent and 1.5-45 wt% of assistants, the filler is an inorganic filler, the filler includes spherical silica particles, and the assistants includes any one or any combination of a promoter, a diluent, aplasticizer, a defoaming agent, a dispersant and a pigment. The above formula and the combination of the above components are combined, so the underfill composition has the advantages of low viscosity, low thermal expansion coefficient, high thermal conductivity, high flexural strength, can solve the problem of the frequent occurring solder joint drop or fracture in the thermal cycle test, and also has the advantages of long-term usability, good adhesion and excellent mechanical properties.

Owner:深圳泰研半导体装备有限公司

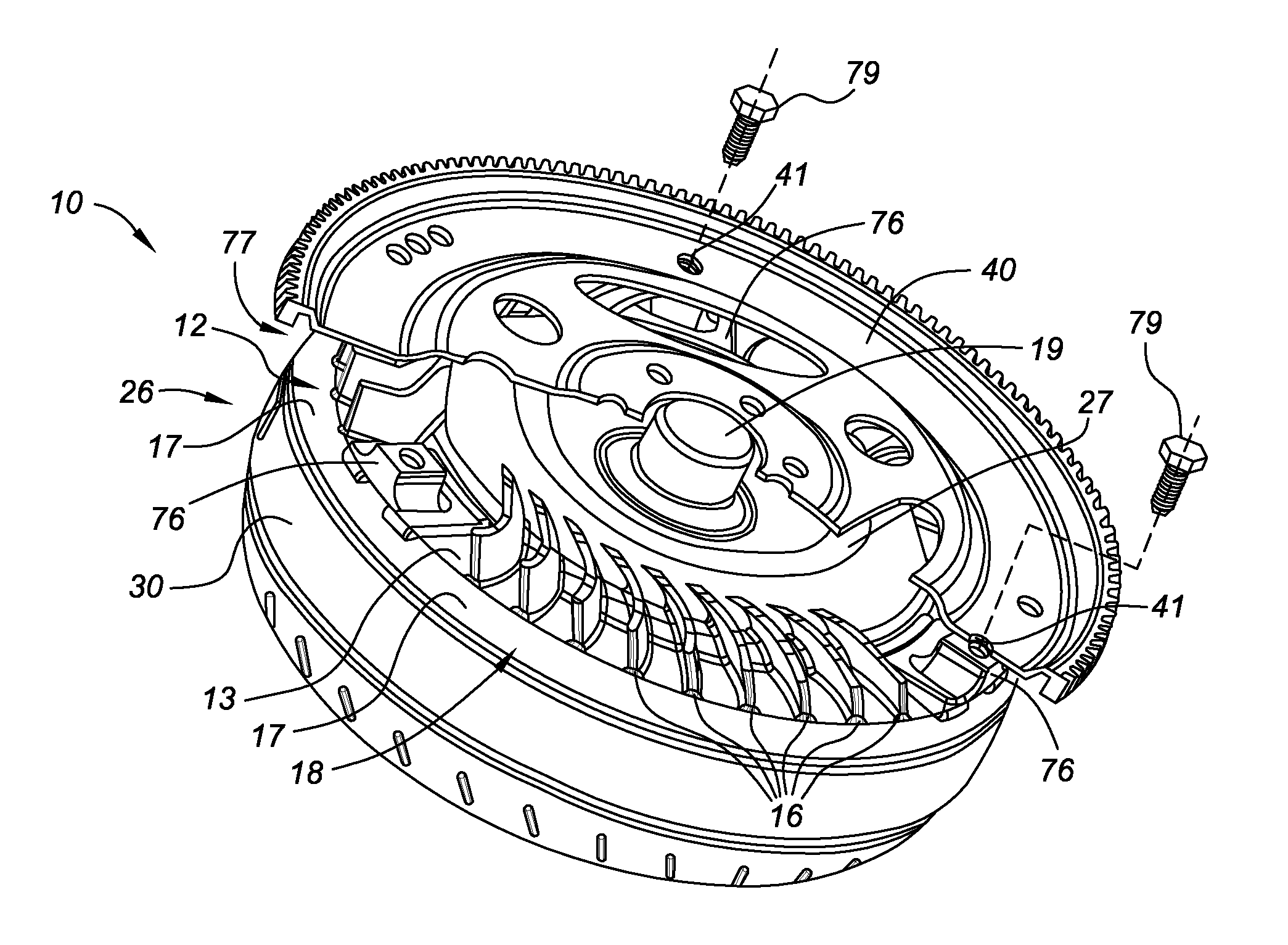

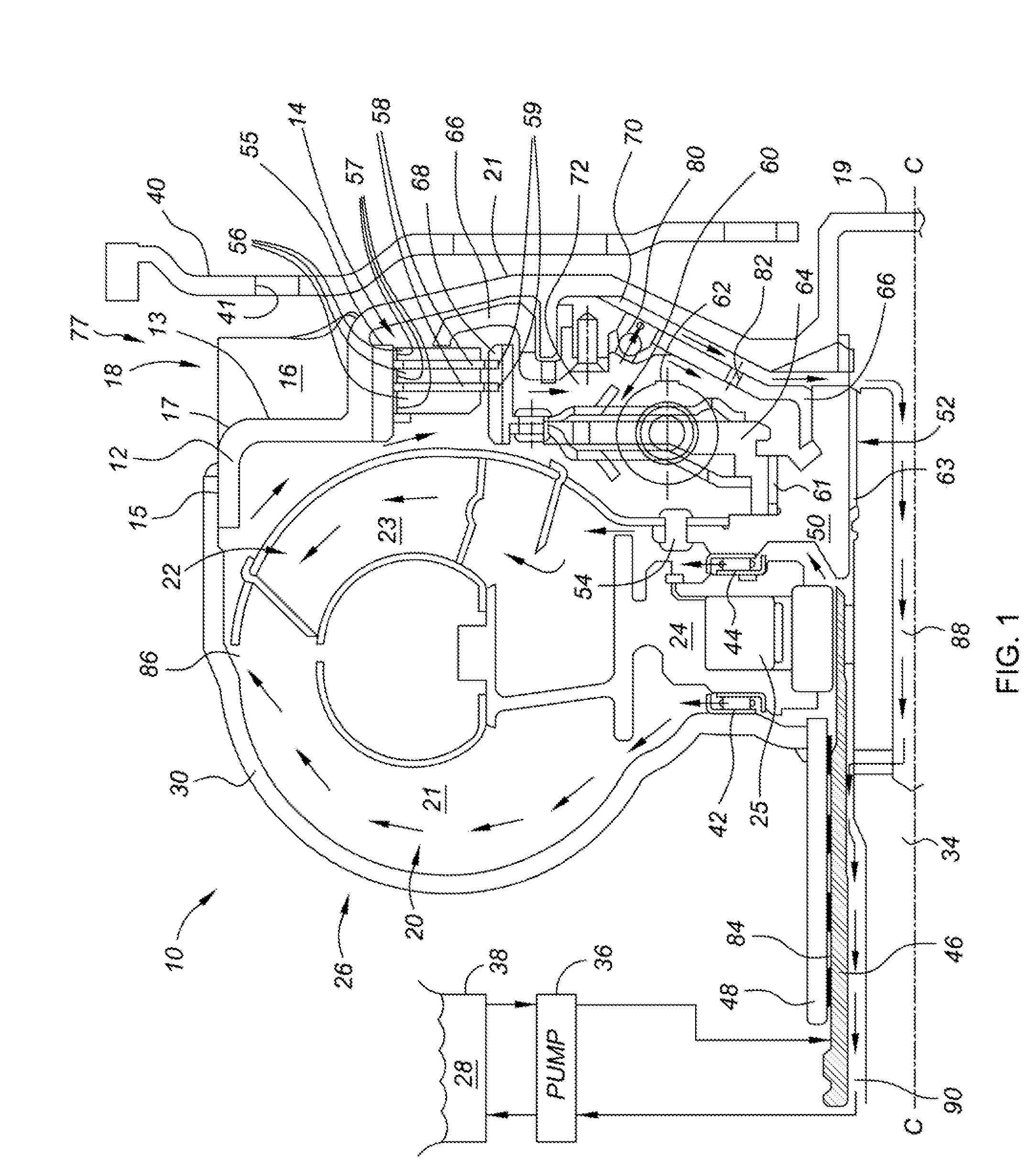

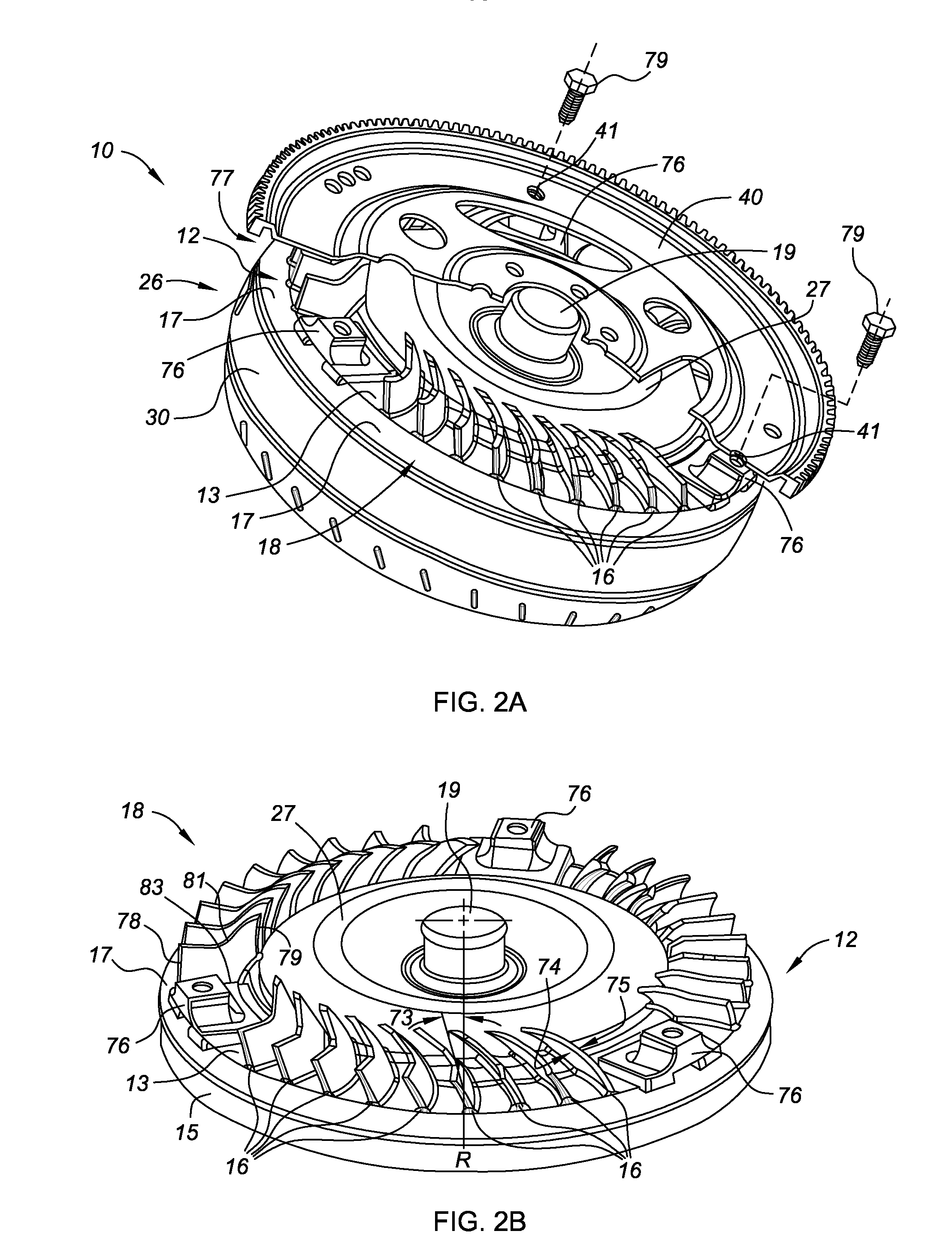

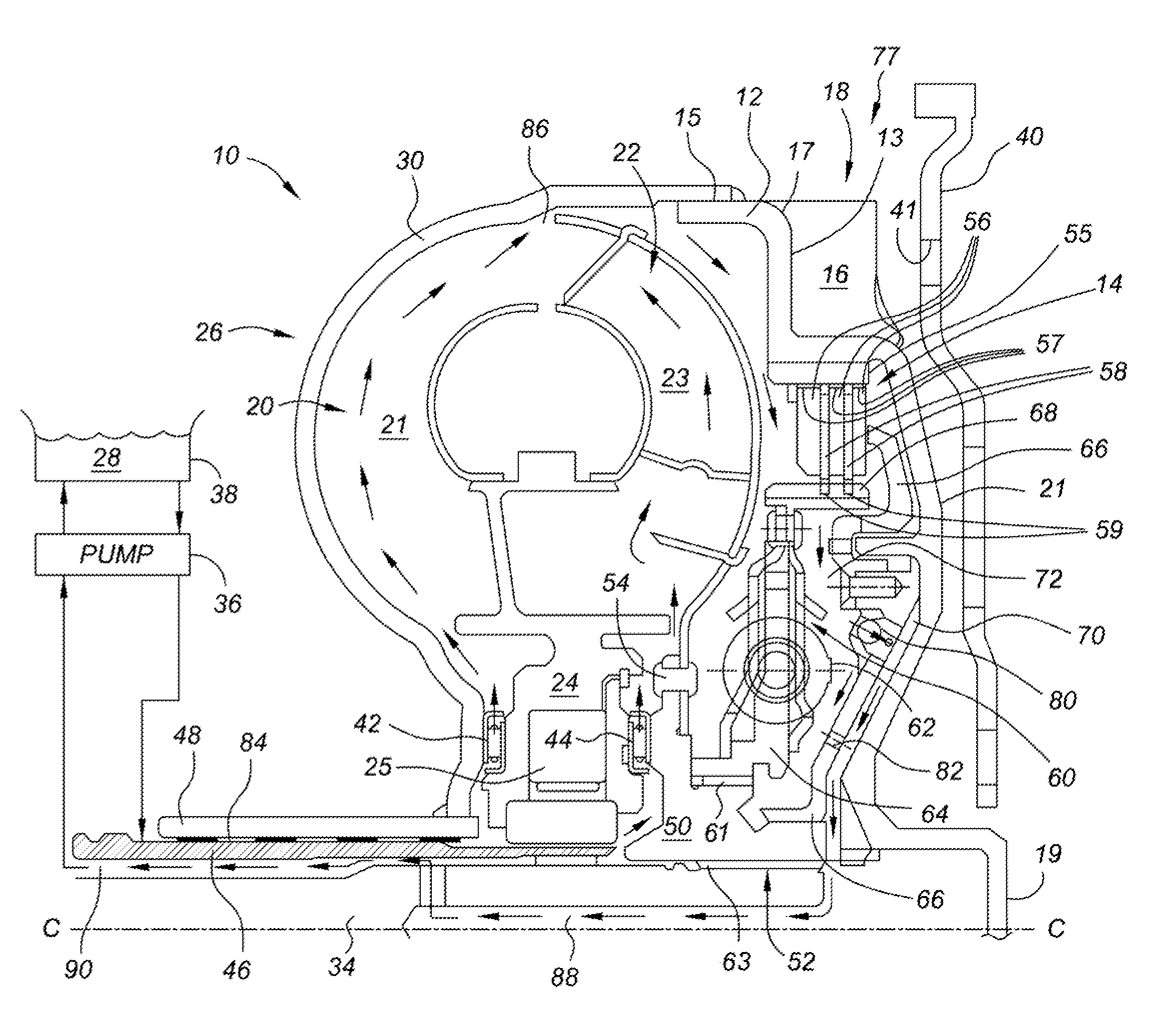

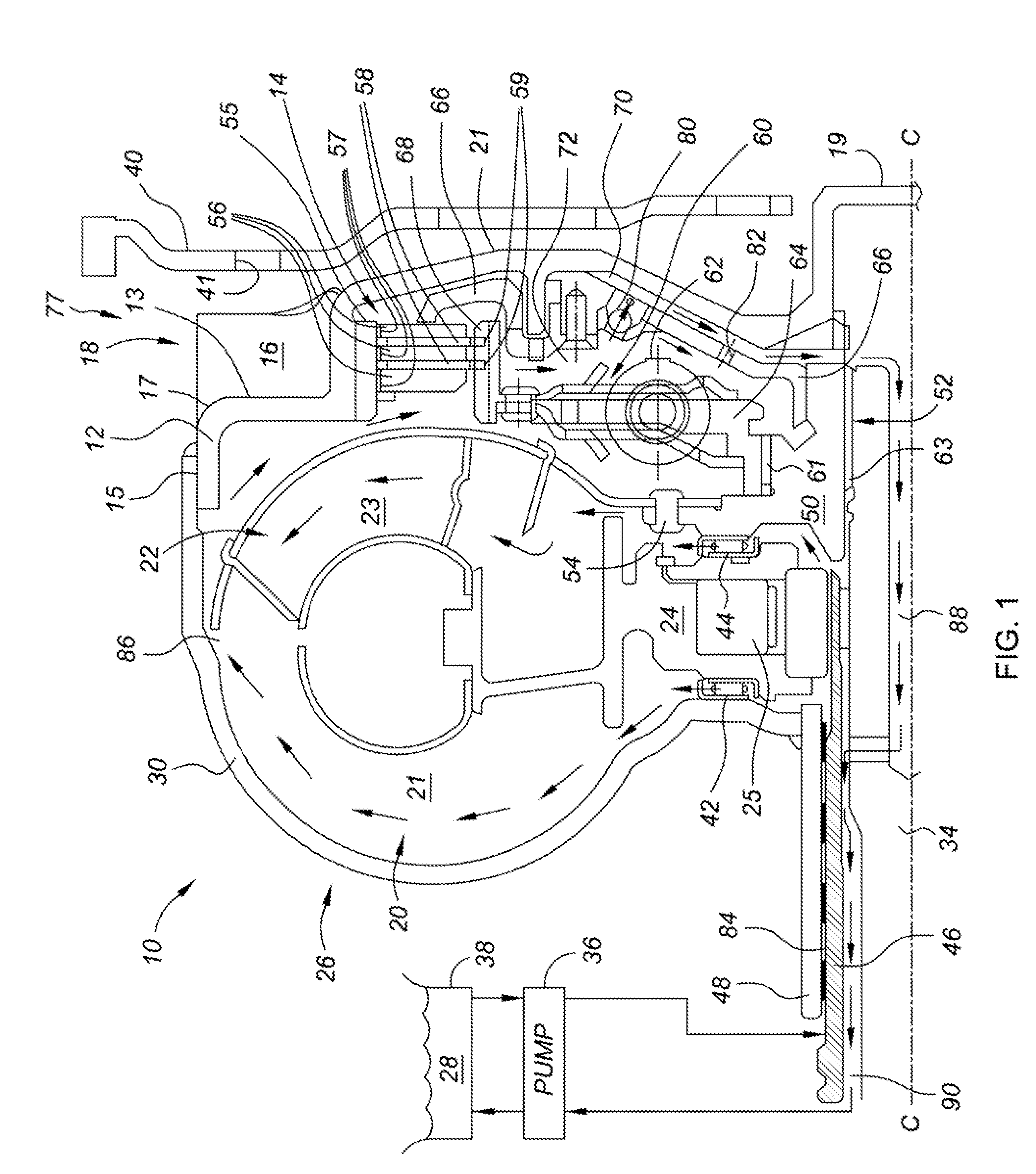

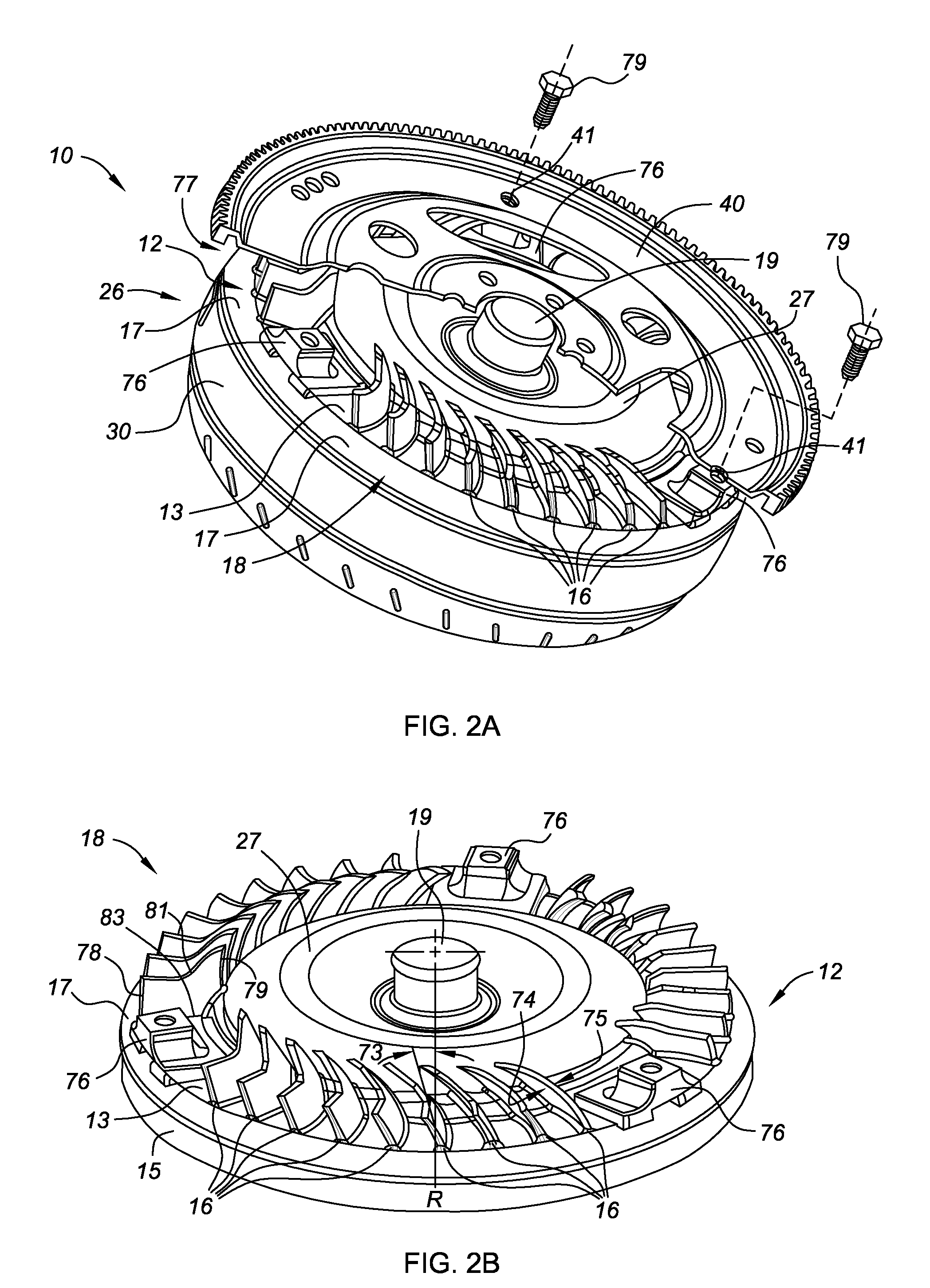

Vane air-cooling system for automatic transmission torque converter

InactiveUS20090035129A1Increased convection coolingIncreased durabilityPump componentsFluid gearingsAutomatic transmissionAir cooling system

A cooling system is provided for automatic transmission torque converter assemblies having a housing shell and flex plate. The cooling system includes a housing cover having opposing exterior and interior surfaces that define a wall portion and a preferably circular base portion. The base portion is configured to attach to the flex plate, preferably by one or more stud members, to be rotated thereby. The wall portion extends from a periphery of the base portion and is configured to attach to the housing shell. The cooling system also includes a plurality of vane members positioned along the outer periphery of the base portion. The vane members are configured to increase convective dissipation of heat from the torque converter assembly to surrounding ambient air by increasing the heat transfer coefficient and surface area. Optimally, the vanes have a turbine fin configuration, but may alternatively have curved fin or a straight-fin configuration.

Owner:GM GLOBAL TECH OPERATIONS LLC

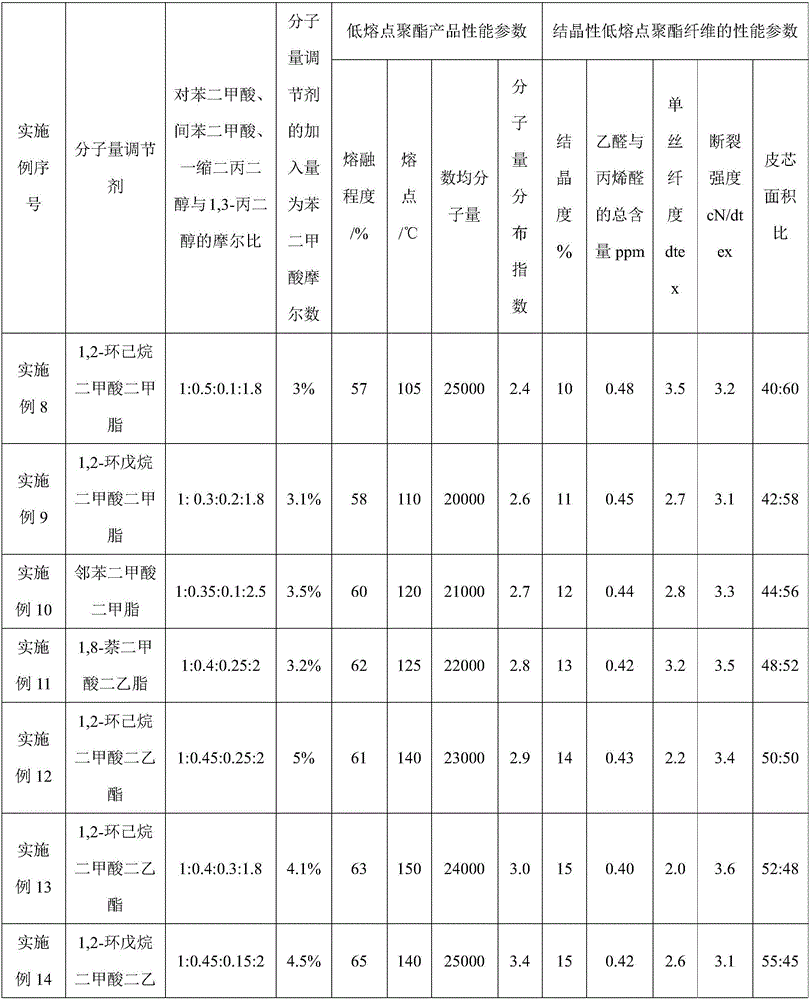

Crystallinity low-melting point polyester fiber and preparation method thereof

ActiveCN106811829AImprove cohesive energyFast curingConjugated synthetic polymer artificial filamentsStretch-spinning methodsFiberPolymer science

The invention relates to a crystallinity low-melting point polyester fiber and a preparation method thereof; the crystallinity low-melting point polyester fiber is a belt core structure, wherein a belt layer is a low-melting-point polyester, and a core layer is PET; the low-melting point polyester fiber consists of terephthalic acid chain section, isophthalic acid chain section, 1, 3-propylene glycol chain section, dipropylene glycol chain section and molecular weight modifier, wherein the molecular weight modifier corresponding to the molecular weight modifier chain section is 1, 8-naphthalic acid, phthalic acid, 1, 2-cyclopentane dioctyl phthalate, 1, 2-cyclohexane dioctyl phthalate or corresponding dimethyl ester or diethyl ester. The preparation method includes low-melting-point polyester polymerization and belt core composite spinning, wherein post spinning adopts drafting-water washing technique, and drafting adopts oil bath drafting added with sodium sulfite; through rolling, cutting and drying, the crystallinity low-melting point polyester fiber is acquired. The crystallinity low-melting point polyester fiber prepared by the invention is low in melting point, and low in total content of acetaldehyde and acrolein.

Owner:扬州富威尔复合材料有限公司

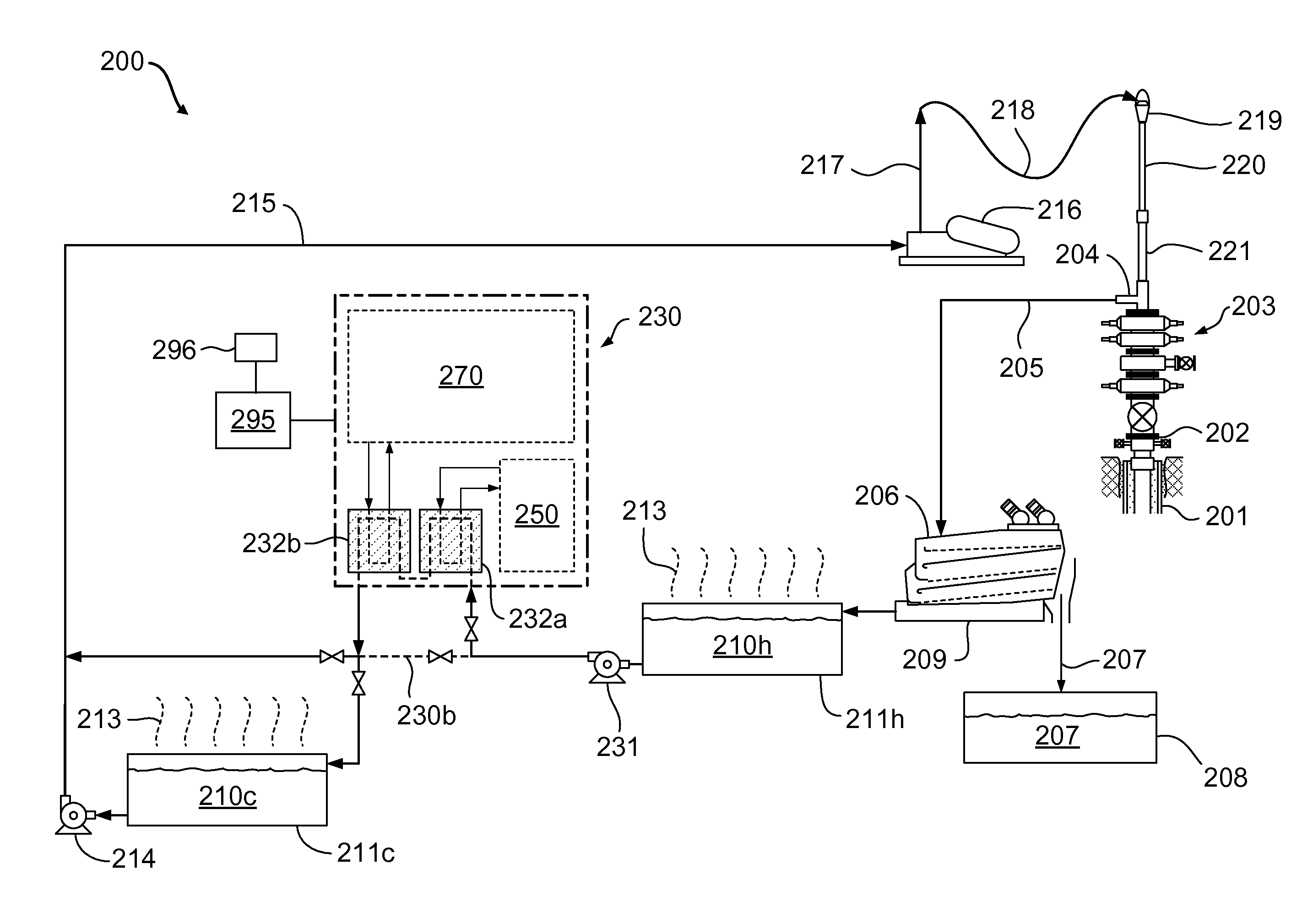

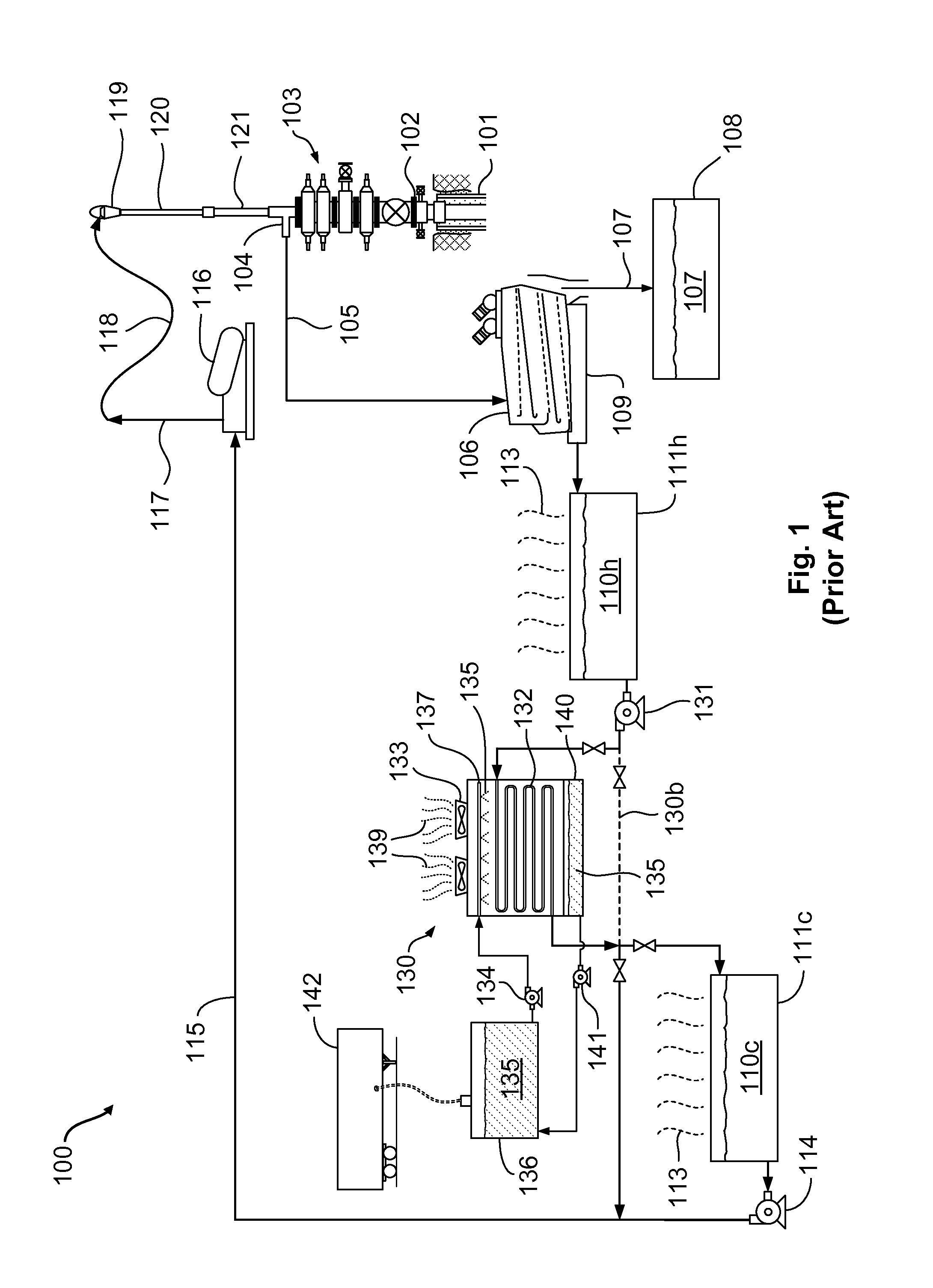

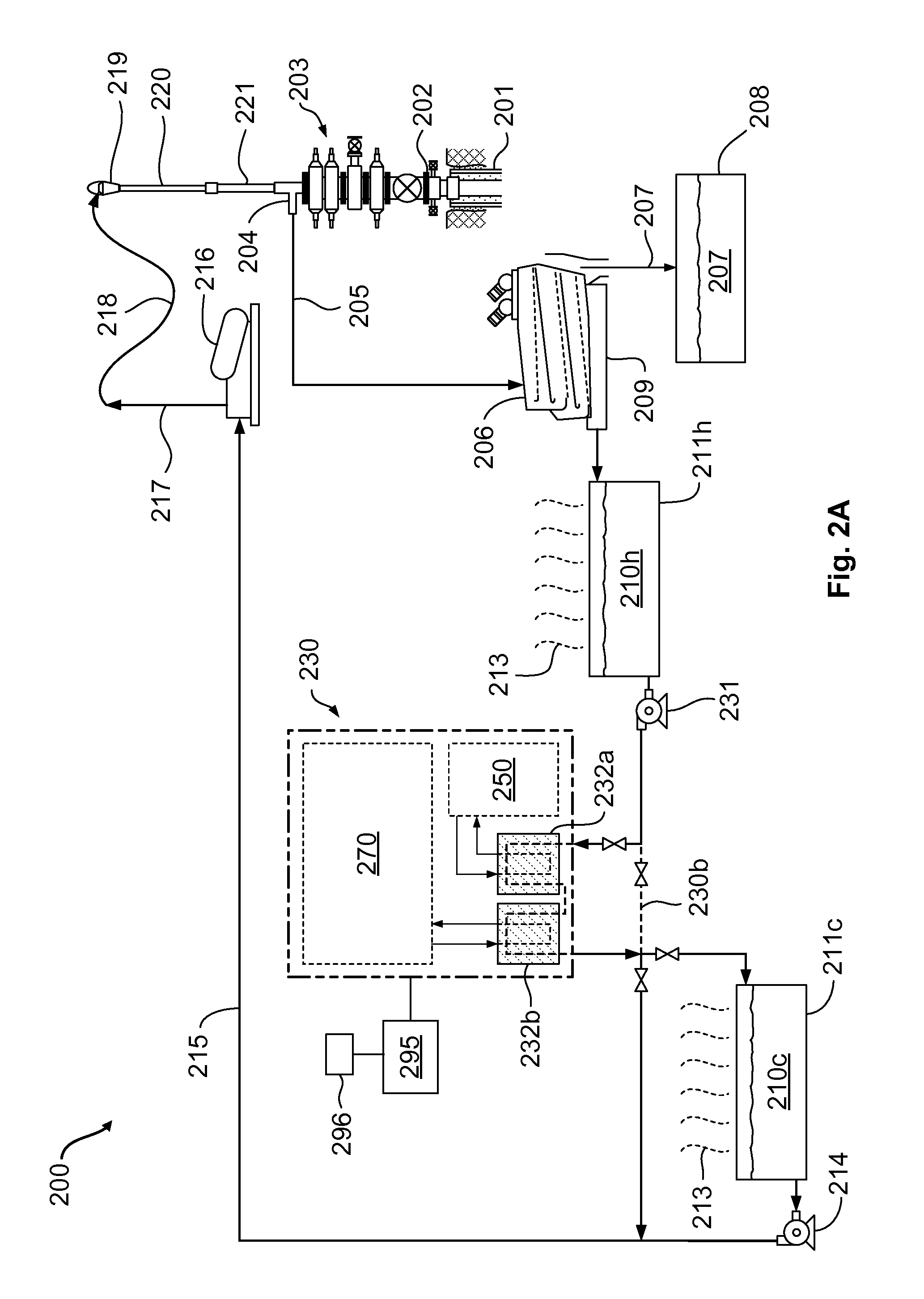

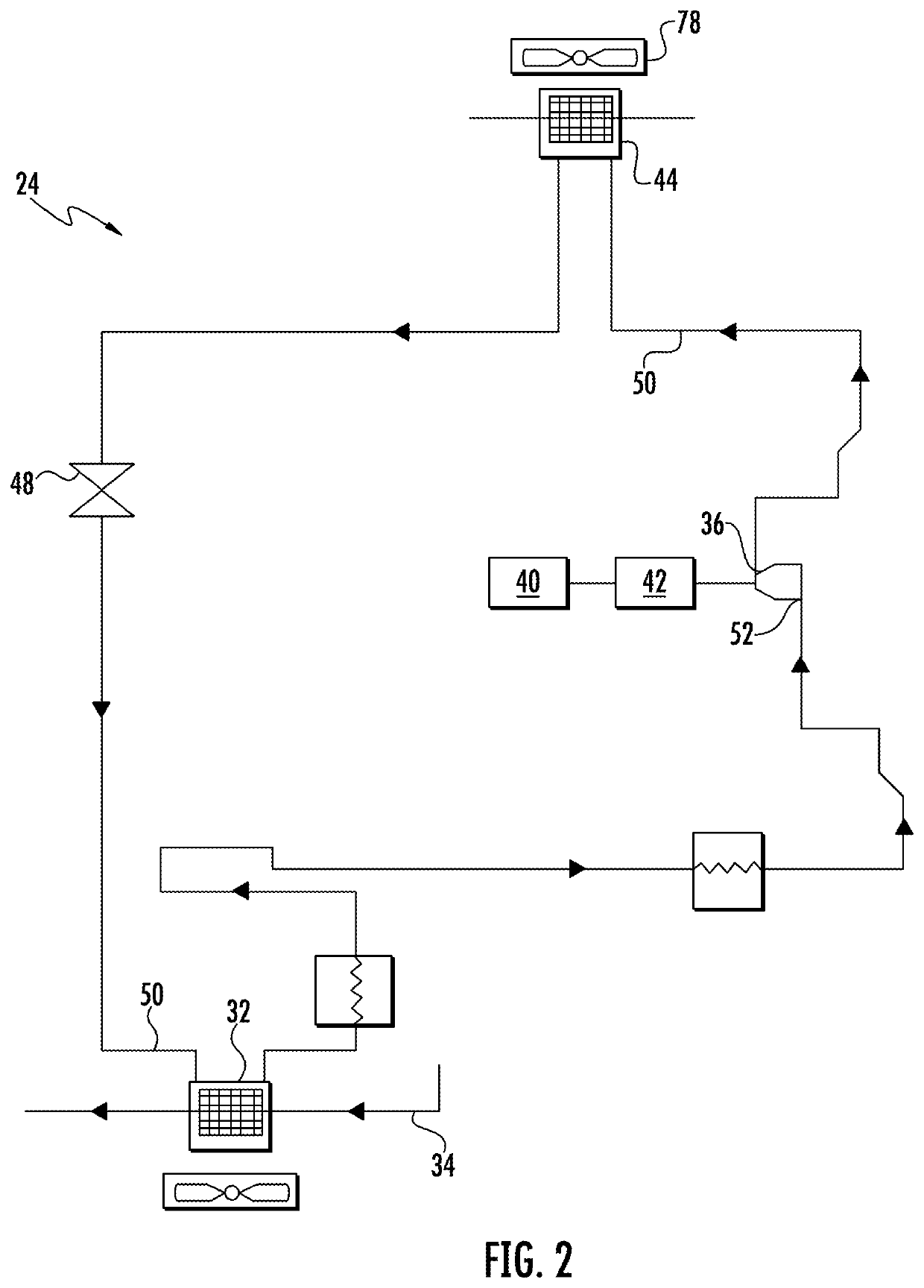

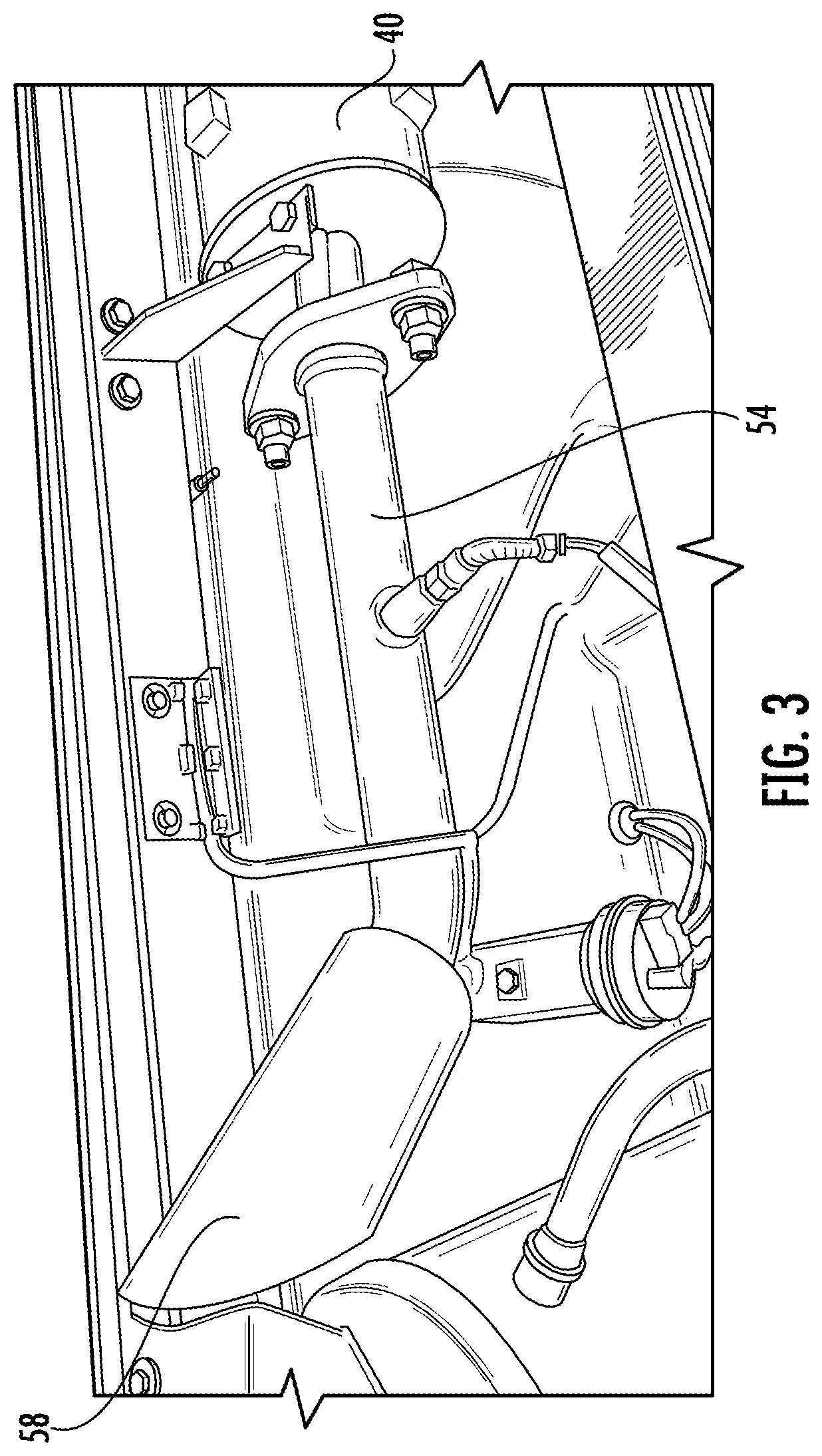

Closed loop drilling mud cooling system for land-based drilling operations

ActiveUS20160010407A1Well formedReduce the temperatureConstructionsInsulationWell drillingLand based

A drilling mud cooler includes a first mud heat exchanger that is adapted to receive a flow of drilling mud, a first closed-loop cooling system that is adapted to cool a first cooling fluid that is circulated through the first mud heat exchanger so as to reduce a temperature of the flow of drilling mud from a first temperature to a second temperature, a second mud heat exchanger that is adapted to receive the flow of reduced temperature drilling mud from the first mud heat exchanger, and a second closed-loop cooling system that is adapted to cool a second cooling fluid that is circulated through the second mud heat exchanger so as to further reduce the temperature of the flow of drilling mud from the second temperature to a third temperature.

Owner:NAT OILWELL VARCO LP

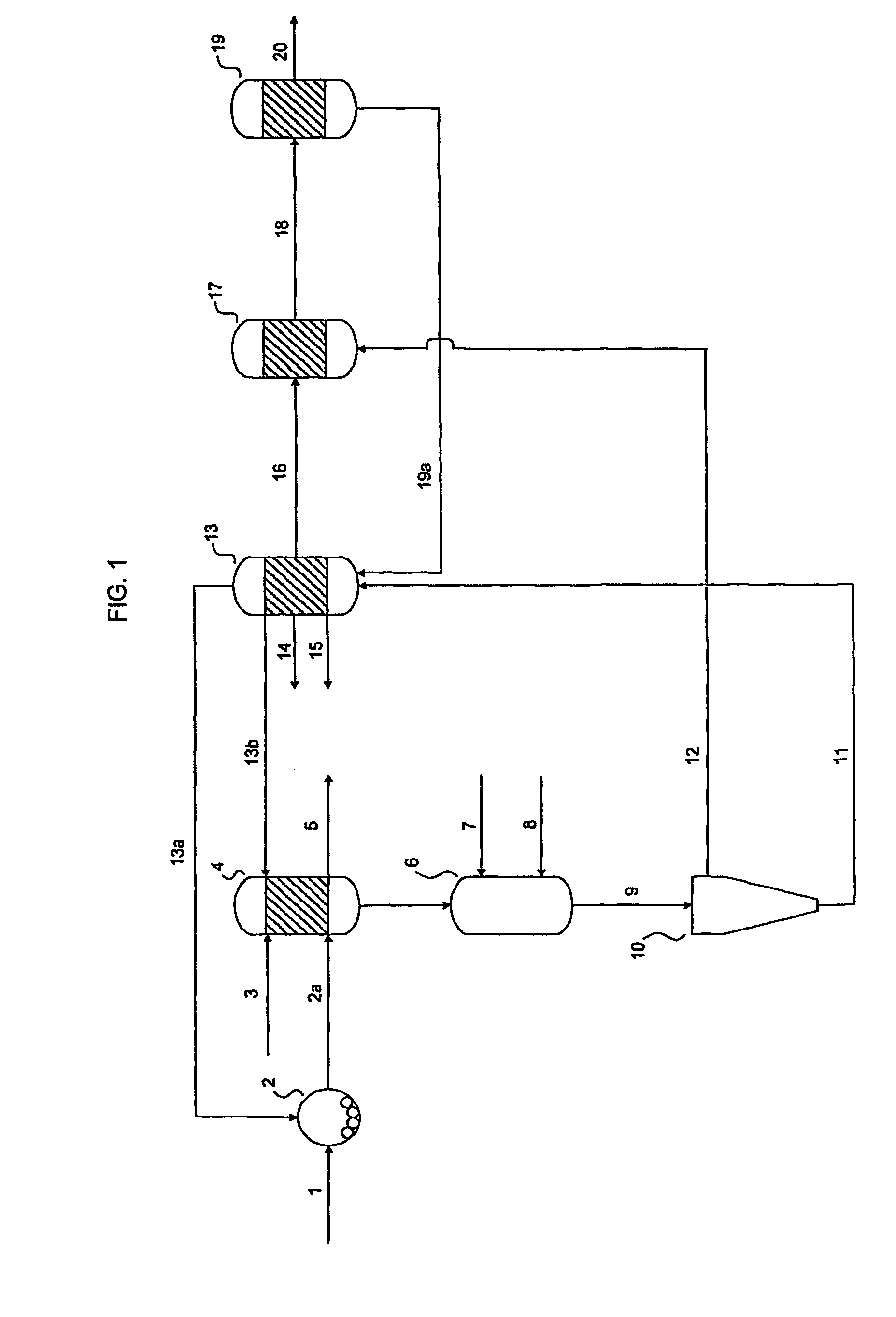

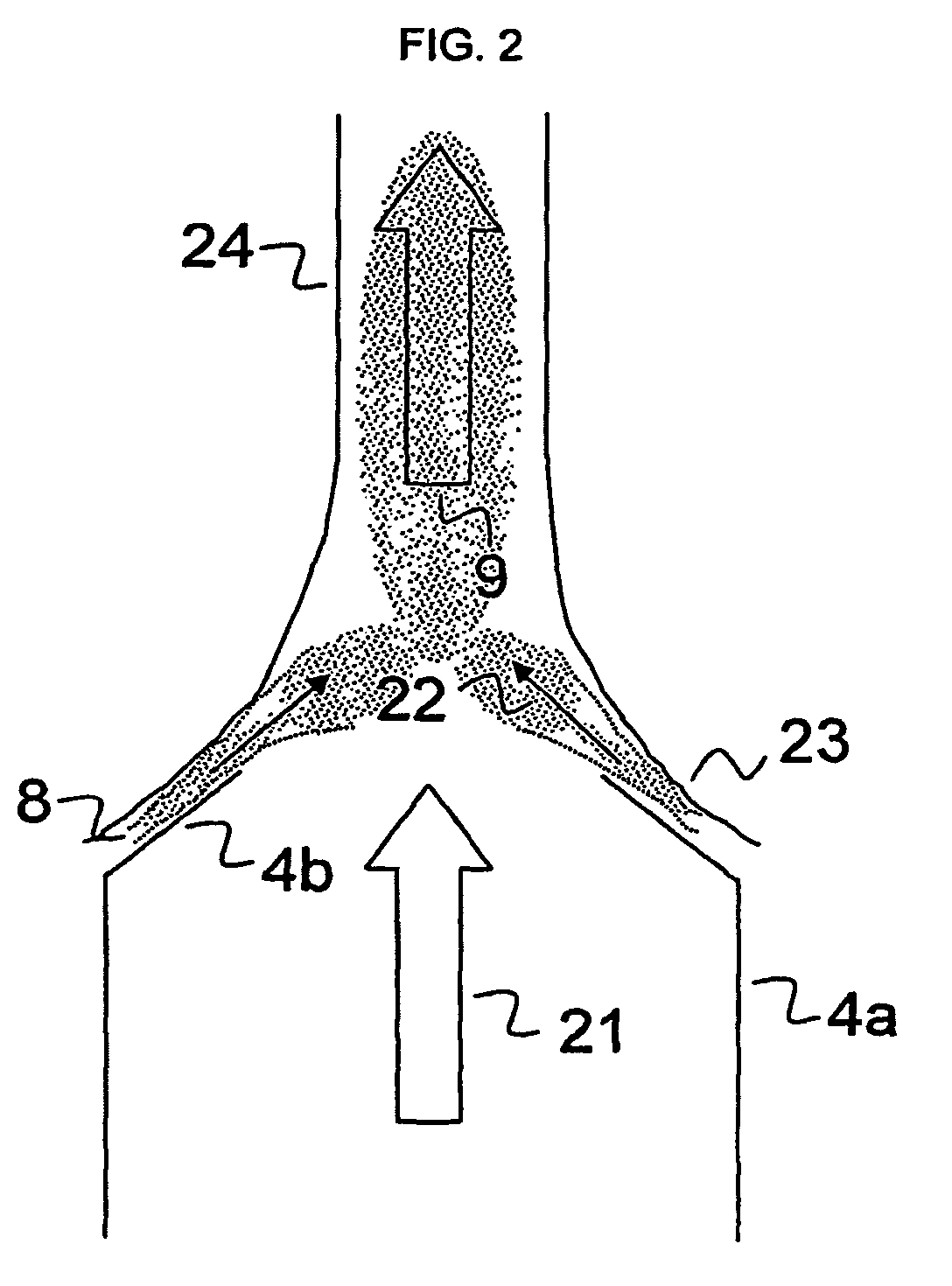

Method for cooling air and devices

ActiveUS8978381B2Lower flow temperatureExtract energyDomestic cooling apparatusSemiconductor/solid-state device detailsCold airElectricity

A method of constructing self-powered air-conditioner comprises a convergent divergent nozzle where powered fan pushes air into said nozzle. While the pushed air accelerates toward the nozzle throat it becomes colder as air internal energy transformed into kinetic energy. An axial turbine installed within the nozzle throat extracts energy from the air in the nozzle and drives an electrical generator that provides electricity to the fan electric motor. Alternatively the turbine and fan are installed on common shaft, which could be the electric generator shaft. The cold air within the nozzle throat cools the nozzle throat skin, which serves as air-conditioner core. The cold nozzle skin is wrapped with coiled pipes in which liquid flows, becomes colder and this cold liquid flows away to heat exchanger where air is flowing through it and becomes colder. This cold air is then flows into spaces needed to be air-conditioned.

Owner:HIRSHBERG ISRAEL

Vane air-cooling system for automatic transmission torque converter

InactiveUS7967561B2Increased durabilityImprove efficiencyPump componentsFluid gearingsAutomatic transmissionEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Slagging fluxing agent for production of electric furnace-process yellow phosphorus

ActiveCN106495111AReduce energy consumptionImprove market competitive advantagePhosphorus compoundsElectric arc furnaceHigh energy

The invention discloses a slagging fluxing agent for production of electric furnace-process yellow phosphorus, and is used for overcoming the fact that a conventional electric furnace-process yellow phosphorus production process takes silica as a fluxing agent, has high reaction and deslagging temperatures, resulting in too high energy consumption proportion in the production cost of yellow phosphorus; albite or nepheline is used for replacing silica as the slagging fluxing agent for production of the electric furnace-process yellow phosphorus, under a condition without changing an original electric furnace-process yellow phosphorus production process and the phosphorus conversion rate, the reaction temperature and the furnace slag melting temperature electric of electric furnace-process yellow phosphorus production are reduced, and thus the energy consumption of the yellow phosphorus production is reduced.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of high flow hydrophilic copolyester

The invention relates to a method for preparing high-fluidity hydrophilic copolyester. A modified component Tween (or polysorbate, hereinafter referred to as Tween) and diol are mixed and beat in accordance with a certain mass ratio, and are added when polyester completes a esterification stage, and a certain mass of titanium transesterification catalyst is supplemented. The titanium transesterification catalyst has high catalytic activity, which can ensure the rapid and efficient transesterification reaction; the Tween and esters complete a transesterification process at lower temperature. After the transesterification reaction is completed, the high-fluidity hydrophilic copolyester is prepared by a polycondensation reaction. In a Tween molecular structure, an HO- [CH2CH2O] chain segment can be reacted with polyester ester to be connected to a polyester molecular chain; meanwhile, A aromatic ring of the polyester has large steric hindrance, and the HO-[CH2CH2O] cannot achieve all reactions, so that the generation of the side effects of branched cross-linking are avoided. The flexible hydrophilic polyester provided by the invention can be widely used for preparing a moisture absorbing and sweat releasing antistatic fiber as an intimate fabric.

Owner:JIANGSU DESAI CHEM FIBER

Corrosion-resistant environment-friendly PVC modified material

The invention discloses a corrosion-resistant environment-friendly PVC modified material. The material comprises the following raw materials in parts by weight; 50-70 parts of PVC resin, 20-40 parts of nitrile rubber, 10-15 parts of a filling agent, 2-6 parts of a heat stabilizer, 1-20 parts of a plasticizer, 20-40 parts of an elastic modifier, 2-4 parts of an antioxidant and 3-5 parts of a lubricant, wherein the PVC resin is ethylene-process PVC resin with a polymerization degree of 1000 to 1200 and a density of 1.35 to 1.45 g / cm<3>; the filling agent is one of calcium carbonate, argil, talcum powder, diatomite and silicon dioxide; the heat stabilizer is prepared from a main stabilizer, an auxiliary stabilizer and an auxiliary agent according to a weight ratio of (20-40): (4-8): 1; the plasticizer is a mixture composed of a non-migration plasticizer PN-1030 and epoxidized soybean oil according to a weight ratio of (13-16): 1; and the elastic modifier is expanded polystyrene with a glass transition temperature of 80-90 DEG C and a density of 1.04-1.06 g / cm<3>. The material has the characteristics of capability of preventing photolysis and thermal decomposition, good elasticity, high tensile strength, good plasticity, good low temperature resistance, environment friendliness and high oxidation and corrosion resistance, and materials of all the components are convenient to obtain.

Owner:浙江金羿高分子科技有限公司

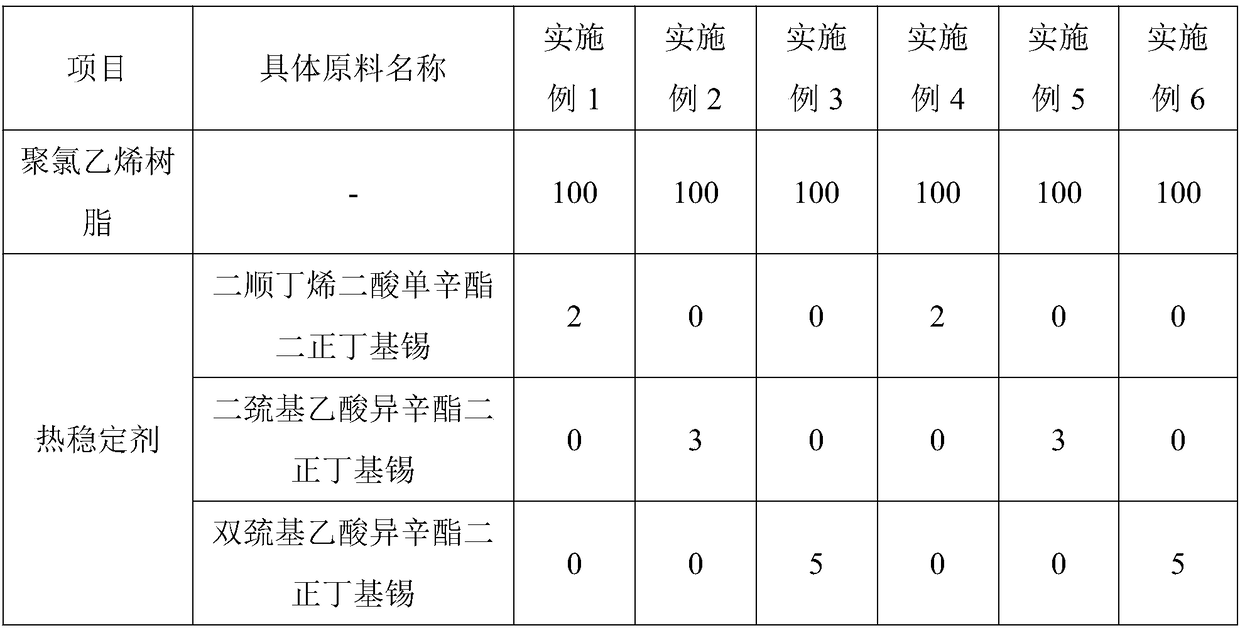

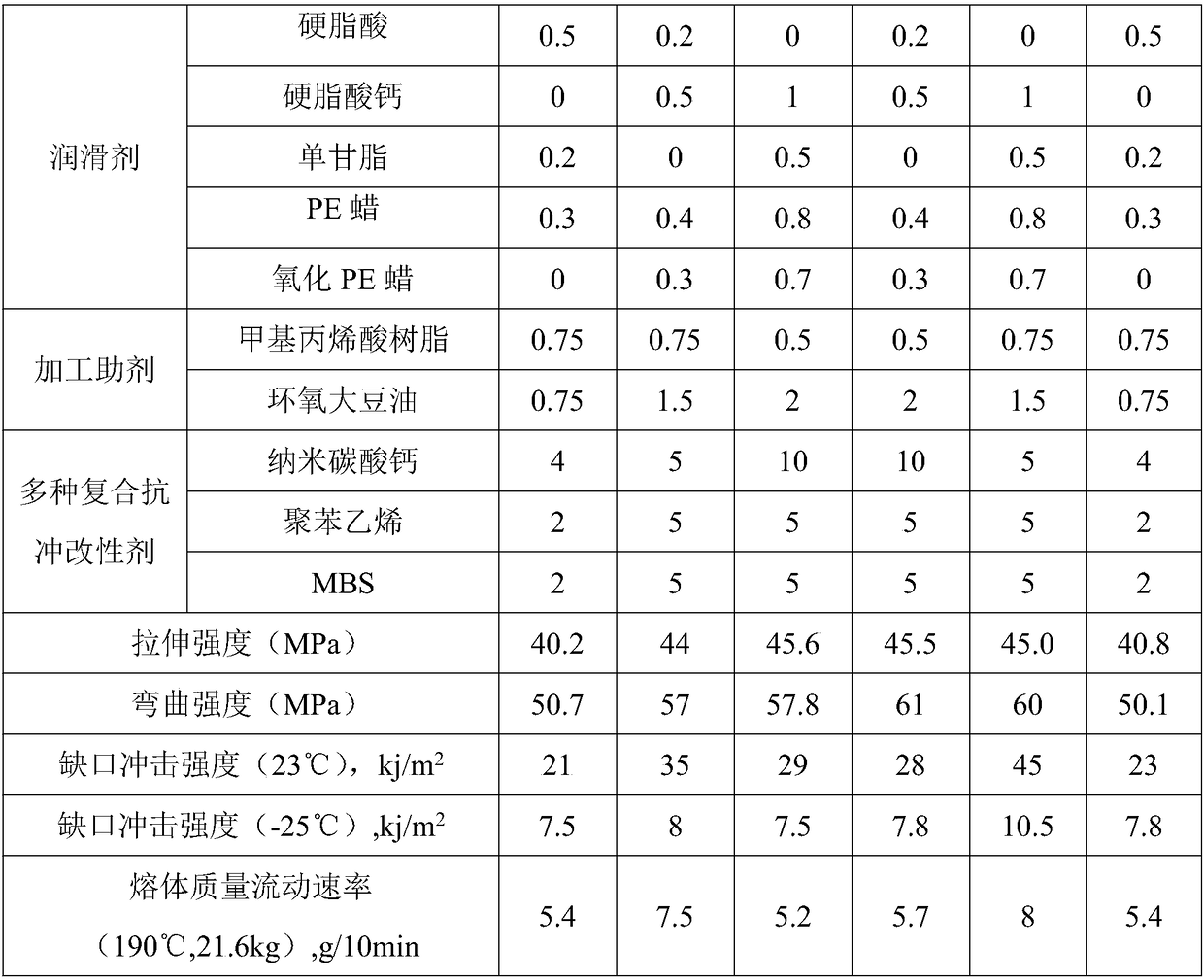

High-impact and high-fluidity polyvinyl chloride material and preparation method thereof

InactiveCN108084609ATo achieve toughening effectLarge specific surface areaPolyvinyl chlorideElectroplating

The invention discloses a high-impact and high-flow polyvinyl chloride material and preparation method thereof. The material has good high-low temperature impact resistance and excellent processing fluidity, and is a composite material which takes the polyvinyl ethylene as the base material and is blended and modified. The material is specifically prepared from the following components in parts byweight: 100 parts of polyvinyl chloride resin, 2-5 parts of heat stabilizer, 1-3 parts of lubricant, 0.5-2.5 parts of processing auxiliary, and 5-20 parts of composite impact modifier. The polyvinylchloride modified material provided by the invention can be used for preparing various pieces through an injection molding way, the traditional ABS material with expensive price is replaced, and the polyvinyl chloride material can be used for wine external package and decorative materials with an electroplating demand.

Owner:宜宾天亿新材料科技有限公司

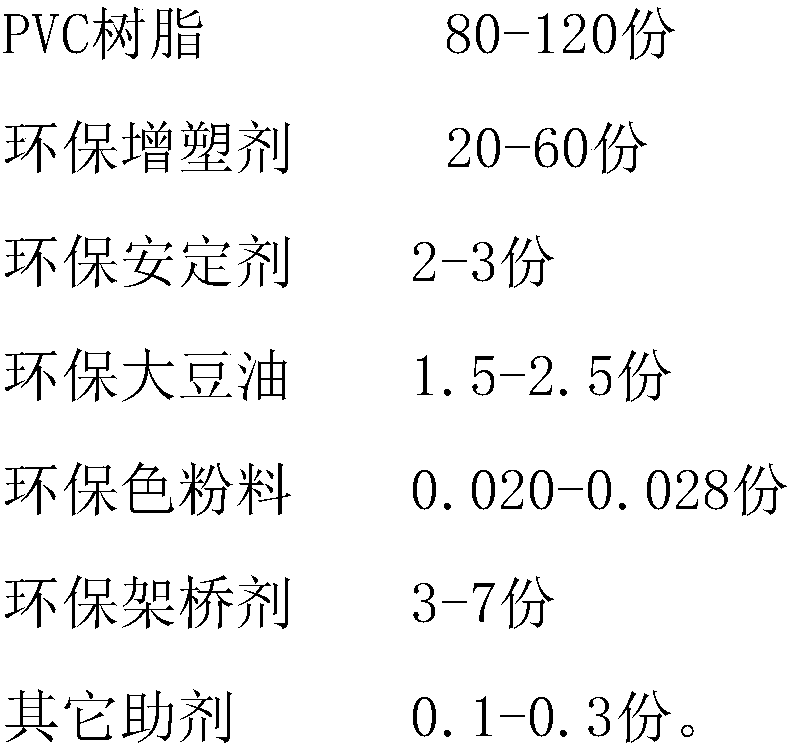

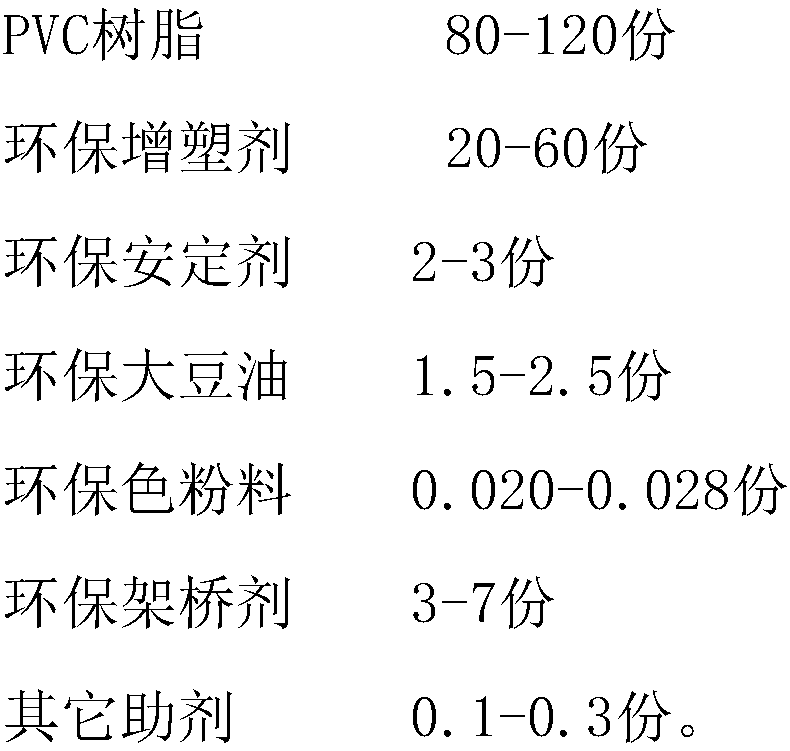

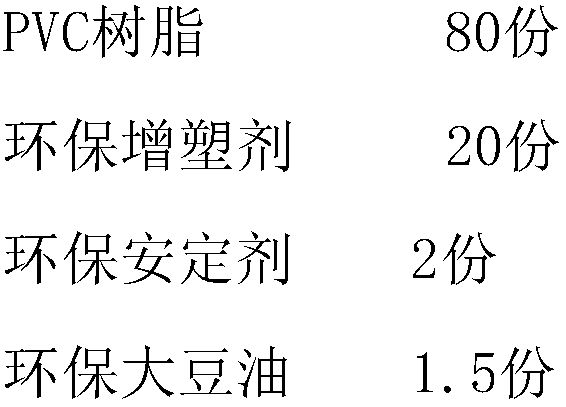

Food-grade polyvinyl chloride film and calendaring process thereof

InactiveCN107698891AFeel goodImprove visual effectsFlat articlesEnvironmental resistancePolyvinyl chloride

The invention relates to the technical field of films, in particular to a food-grade polyvinyl chloride film and a calendaring process thereof. The food-grade polyvinyl chloride film is prepared from,by weight, 80-120 parts of PVC (polyvinyl chloride) resin, 20-60 parts of an environment-friendly plasticizer, 2-3 parts of an environment-friendly stabilizing agent, 1.5-2.5 parts of environment-friendly soybean oil, 0.020-0.028 part of environment-friendly toner, 3-7 parts of an environment-friendly bridging agent and 0.1-0.3 part of other additives. The food-grade polyvinyl chloride film is environmentally friendly, great in handfeel and visual effects and excellent in ultraviolet resistance and water resistance and has advantages of flame retardation, insulation, alkali and acid resistance, cold and mould proofing, corrosion resistance, static resistance, tensile resistance, aging resistance and the like, thereby being excellent in comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Temperature control of exhaust gas of a transportation refrigeration unit

ActiveUS20180355775A1Reduce the temperatureLower flow temperatureInternal combustion piston enginesLighting and heating apparatusTemperature controlRefrigeration

A transportation refrigeration unit includes an evaporator circulating a flow of refrigerant therethrough to cool a flow of supply air flowing over the evaporator, a compressor in fluid communication with the evaporator to compress the flow of refrigerant, and an engine operably connected to the compressor to drive operation of the compressor. The engine includes an exhaust pathway to direct an exhaust gas flow from the transportation refrigeration unit, and a nozzle extending circumferentially around the exhaust pathway defining a nozzle flowpath between the exhaust pathway and the nozzle, the nozzle configured to flow a cooling airflow along the nozzle flowpath to reduce a temperature of the exhaust gas flow.

Owner:CARRIER CORP

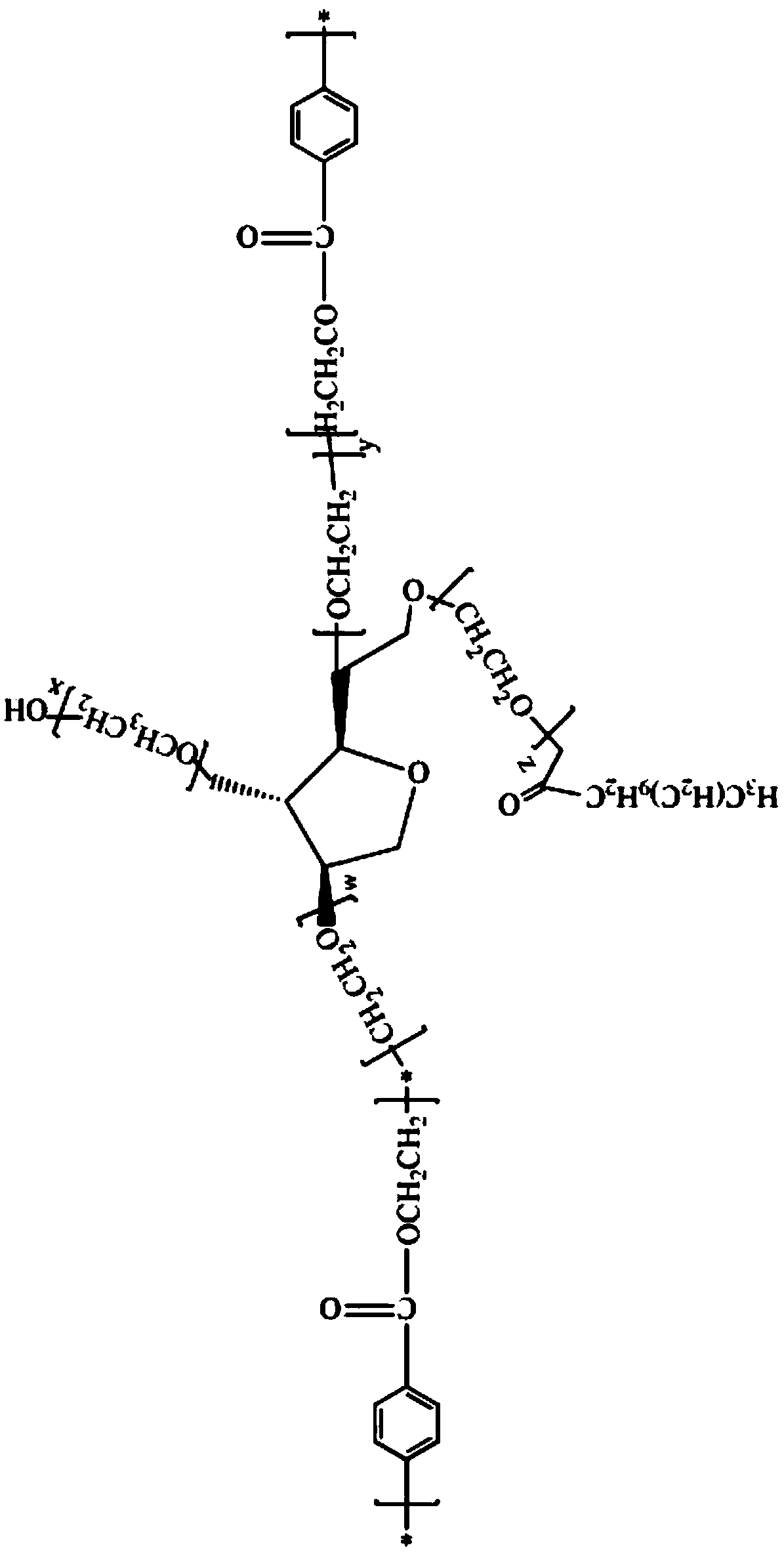

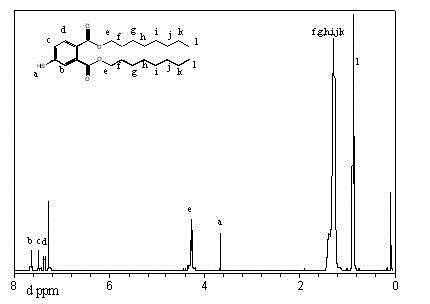

Polyvinyl chloride plasticizer and preparation method thereof

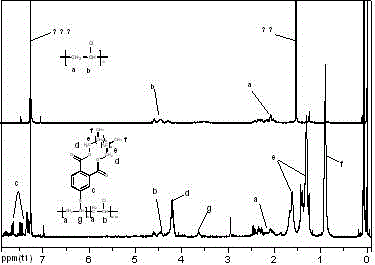

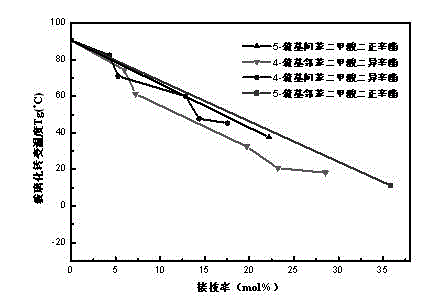

InactiveCN102718690AInhibit migrationLower glass transition temperatureThiol preparationPlasticizerPolyvinyl chloride

The invention belongs to the technical field of a general polymer material, and particularly relates to a polyvinyl chloride plasticizer and a preparation method thereof. Sulfonic acid instead of phthalate is used as a raw material, and mercapto-substituted phthalate is prepared via acyl chlorination, esterification and reduction. When the plasticizer is used, the transformation temperature and flow temperature of PVC (polyvinyl chloride) glass can be reduced, the migration of the plasticizer can be inhibited, and the thermal stability of PVC can be improved. The modified PVC can maintain the stability in a long time, no damage can be caused to the environment, and the scope of application of PVC can be expanded undoubtedly.

Owner:FUDAN UNIV

Aging method of high specific volume aluminum electrolytic capacitor

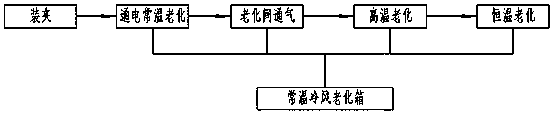

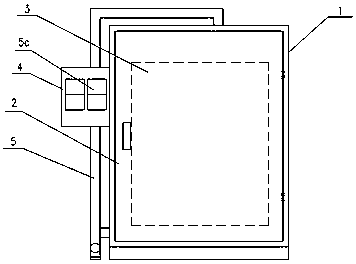

ActiveCN104882279BLower flow temperatureShort boost timeElectrolytic capacitorsAge methodHigh hematocrit

The invention discloses an aging method for a high specific volume aluminum electrolytic capacitor, which comprises a plurality of process steps of clamping, energizing and aging at normal temperature, ventilation in an aging room, high temperature aging and constant temperature aging. Through the air convection device set in the room temperature cold air aging box, the temperature of the air flowing in the room temperature aging room is reduced, so that the temperature of the aluminum electrolytic capacitor itself is lowered during the normal temperature electrification process, so that the voltage can be over-added and quickly rise to the value required by the product process, so that the voltage can be boosted. The time has been shortened from 6 to 8 hours to 3 to 4 hours. Use this method to shorten the aging time of aluminum electrolytic capacitors by 50%, thereby saving 50% of electricity, and the boosting time is short, the leakage current is small, the electrical performance is good, the production cost of the product is greatly reduced, and the input cost is greatly reduced.

Owner:NANTONG HUAYU ELECTRONICS

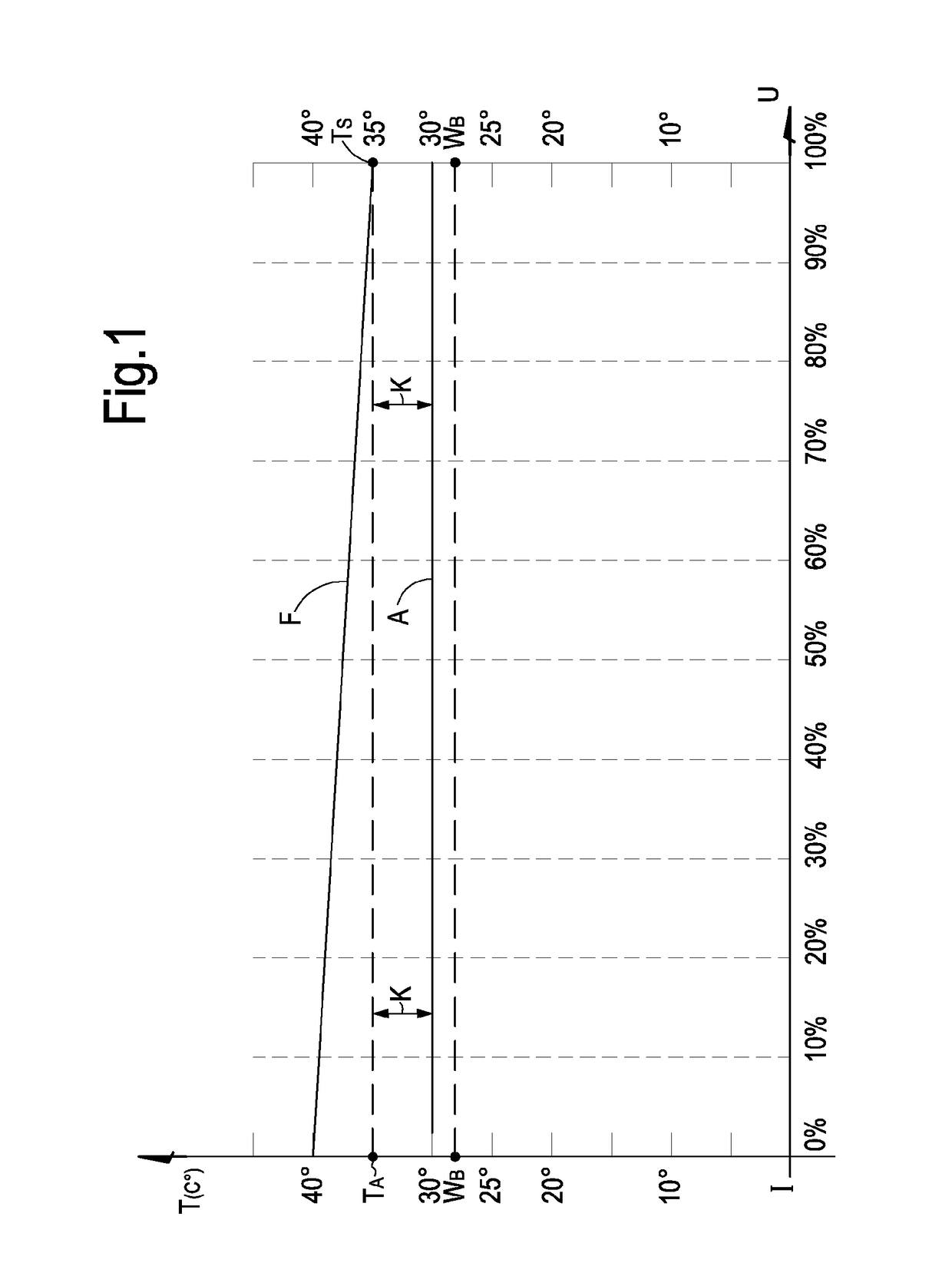

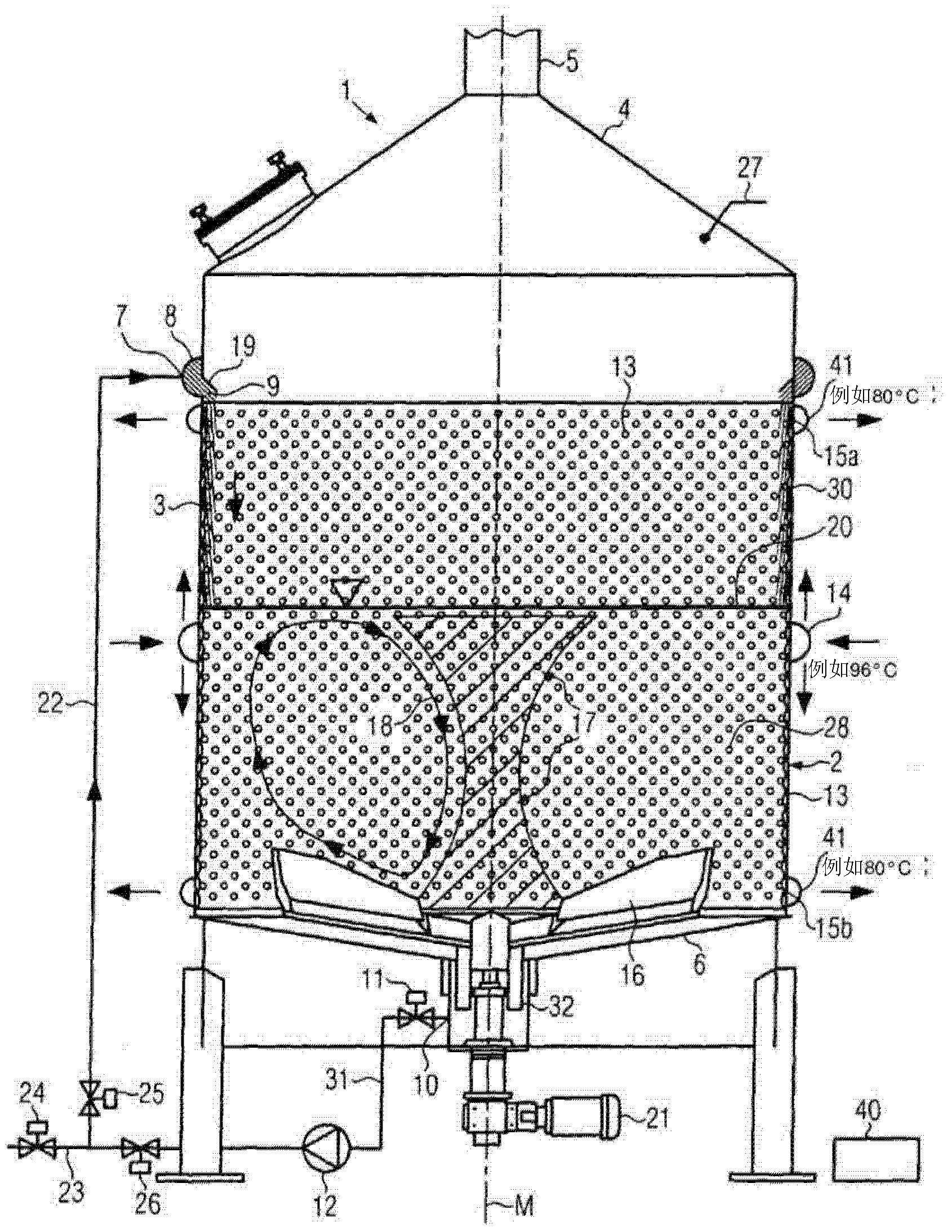

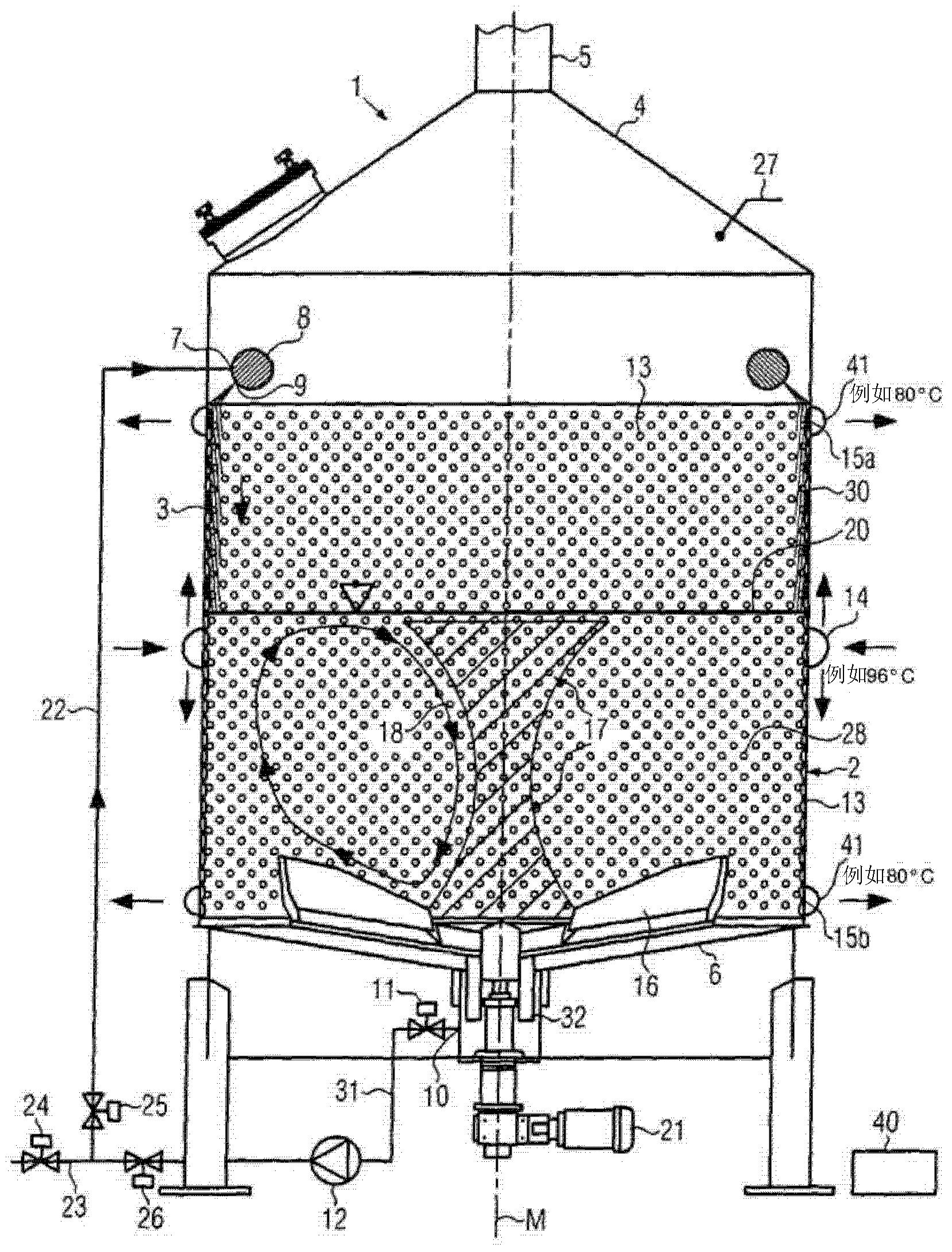

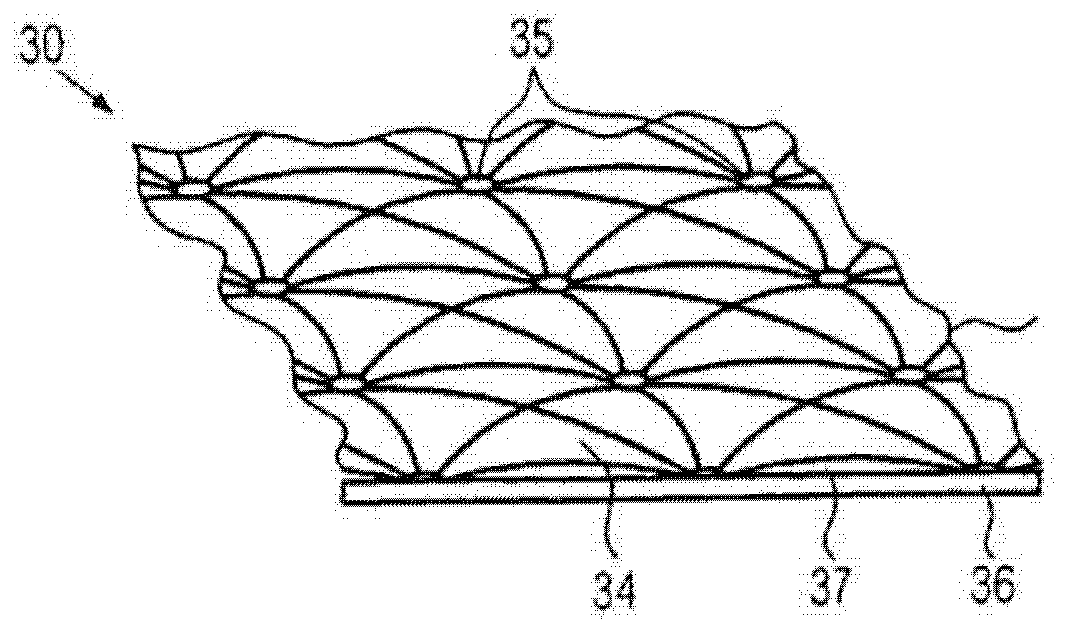

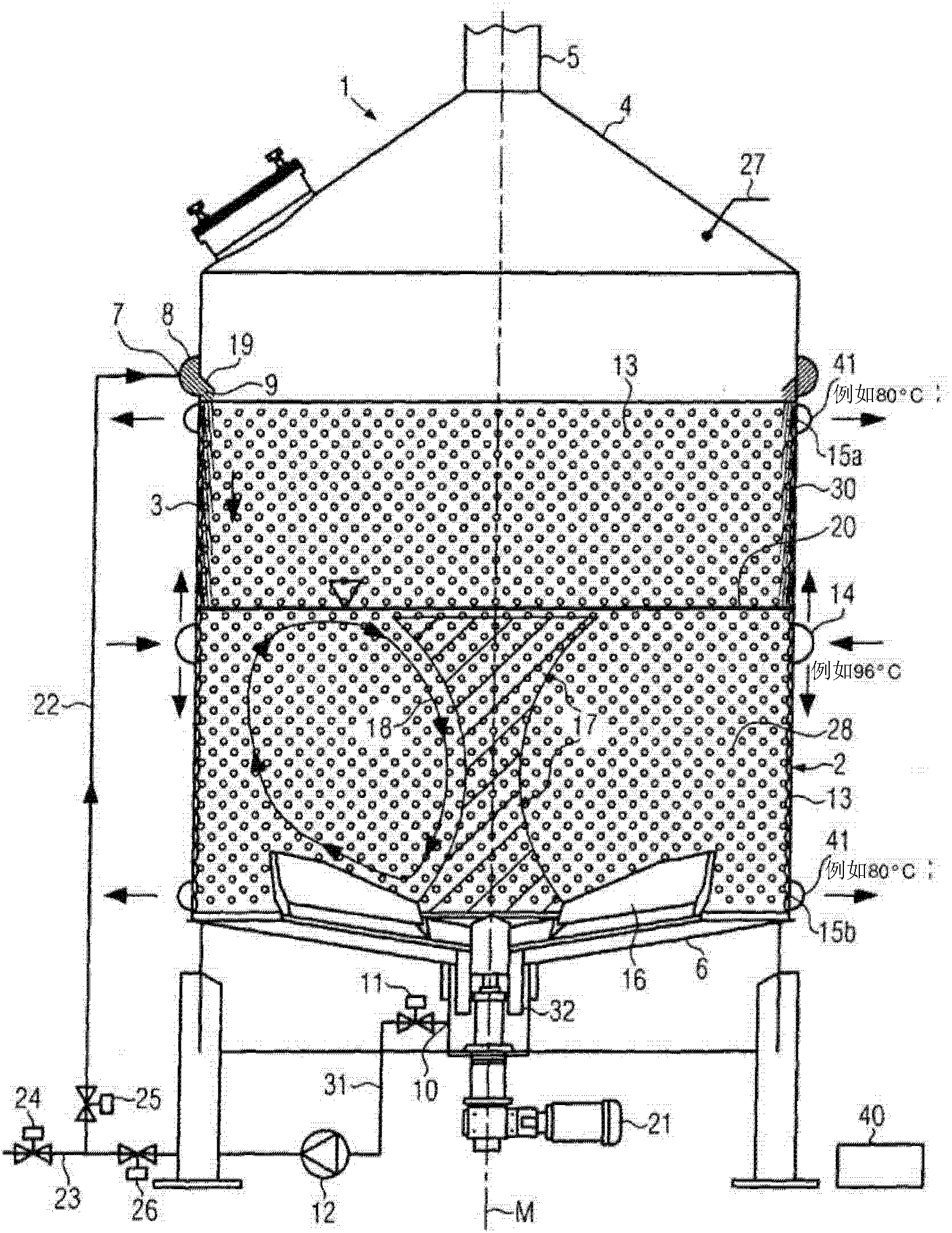

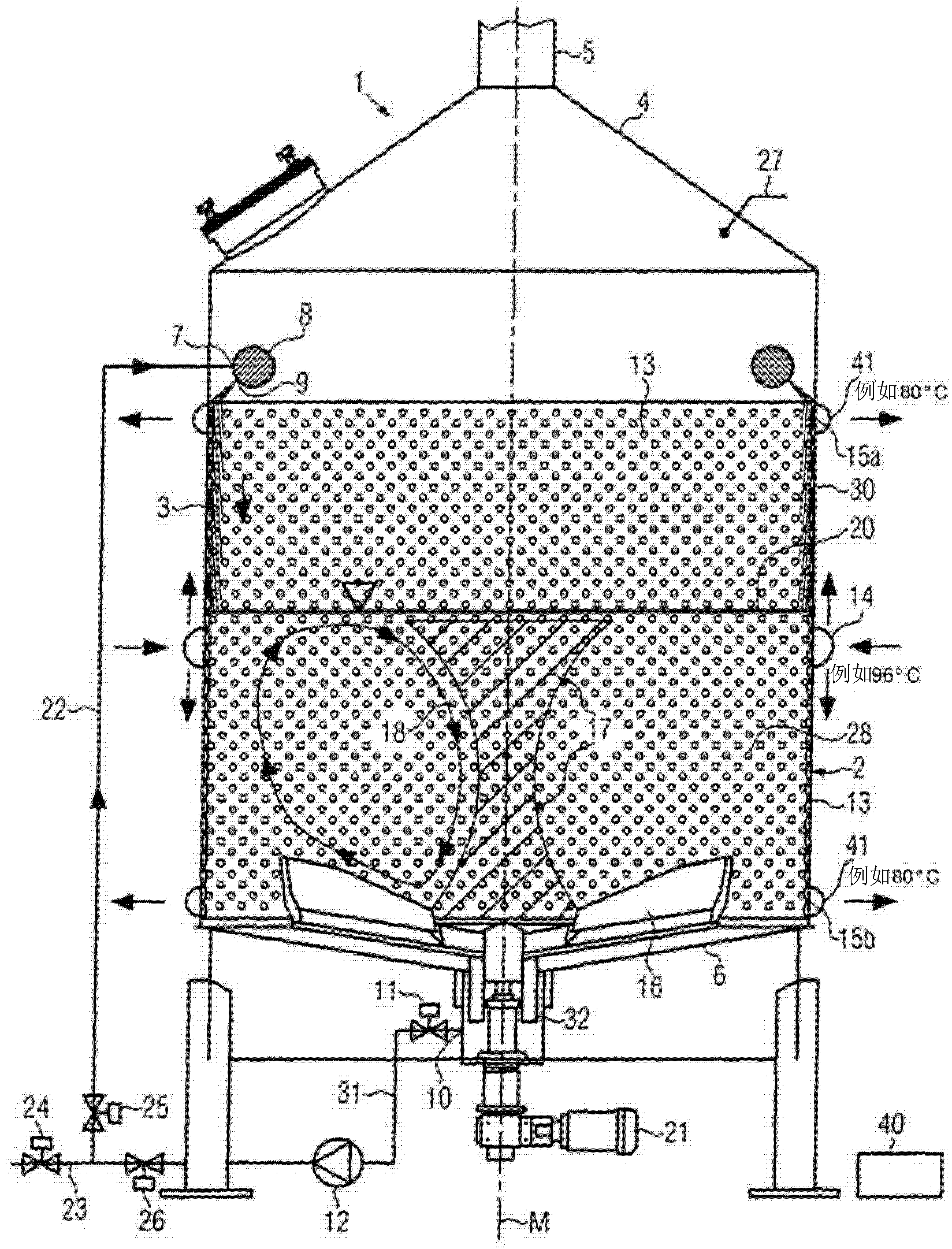

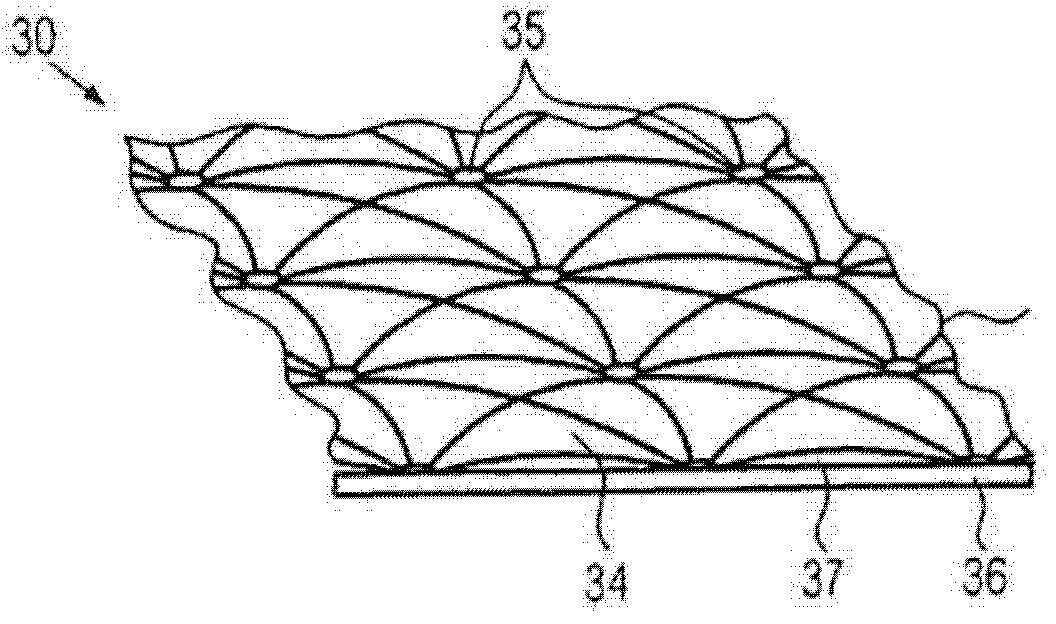

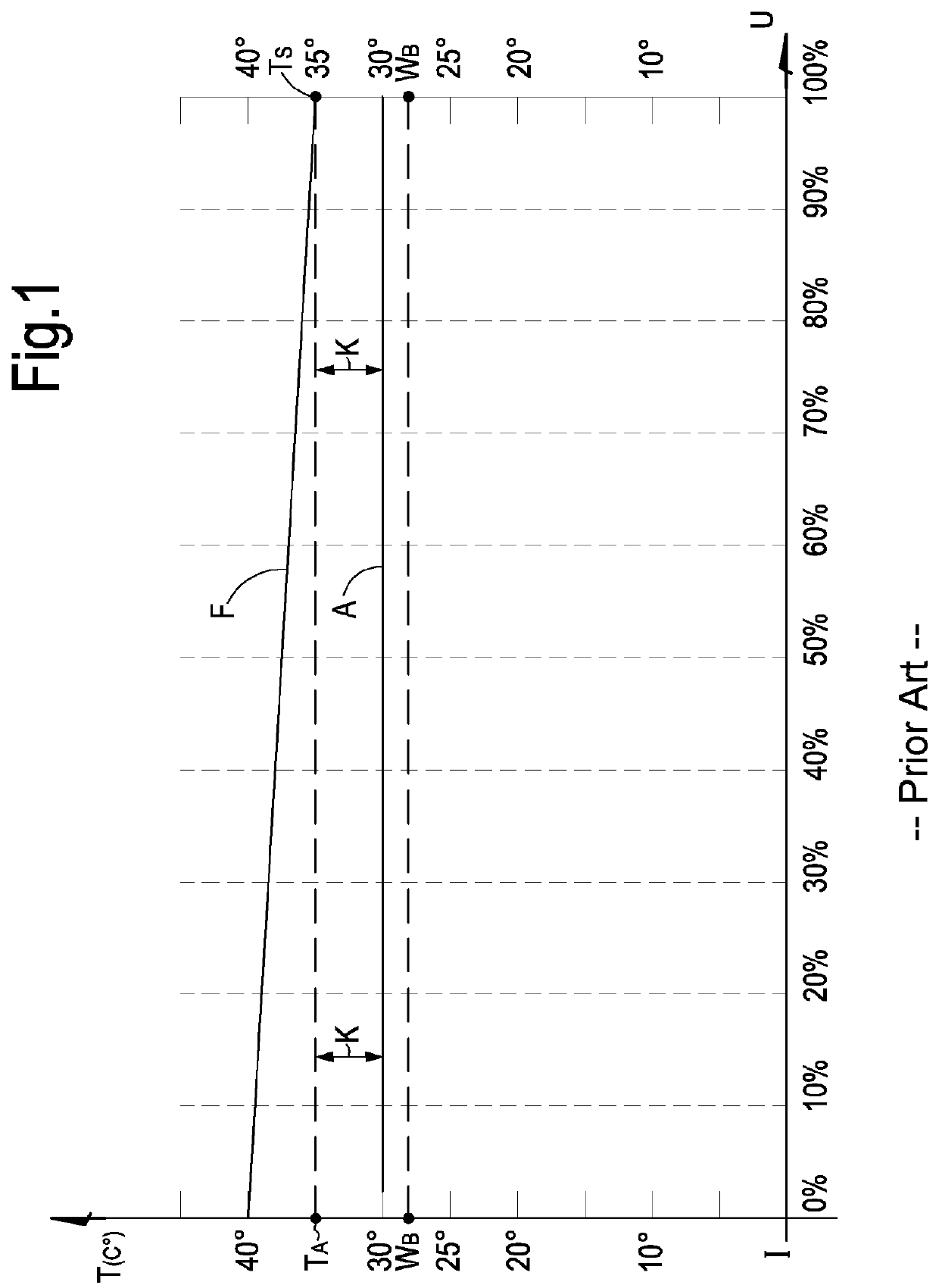

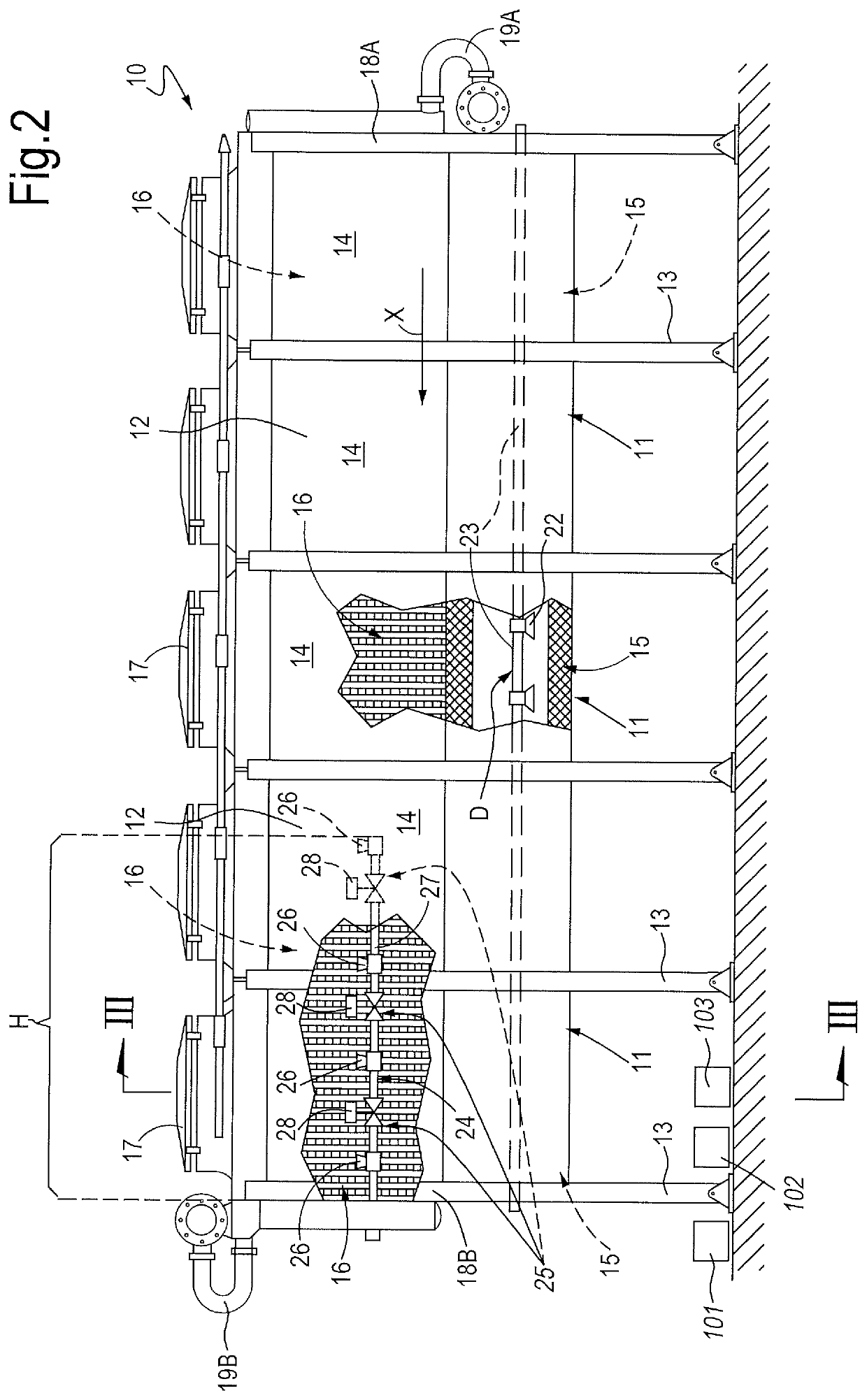

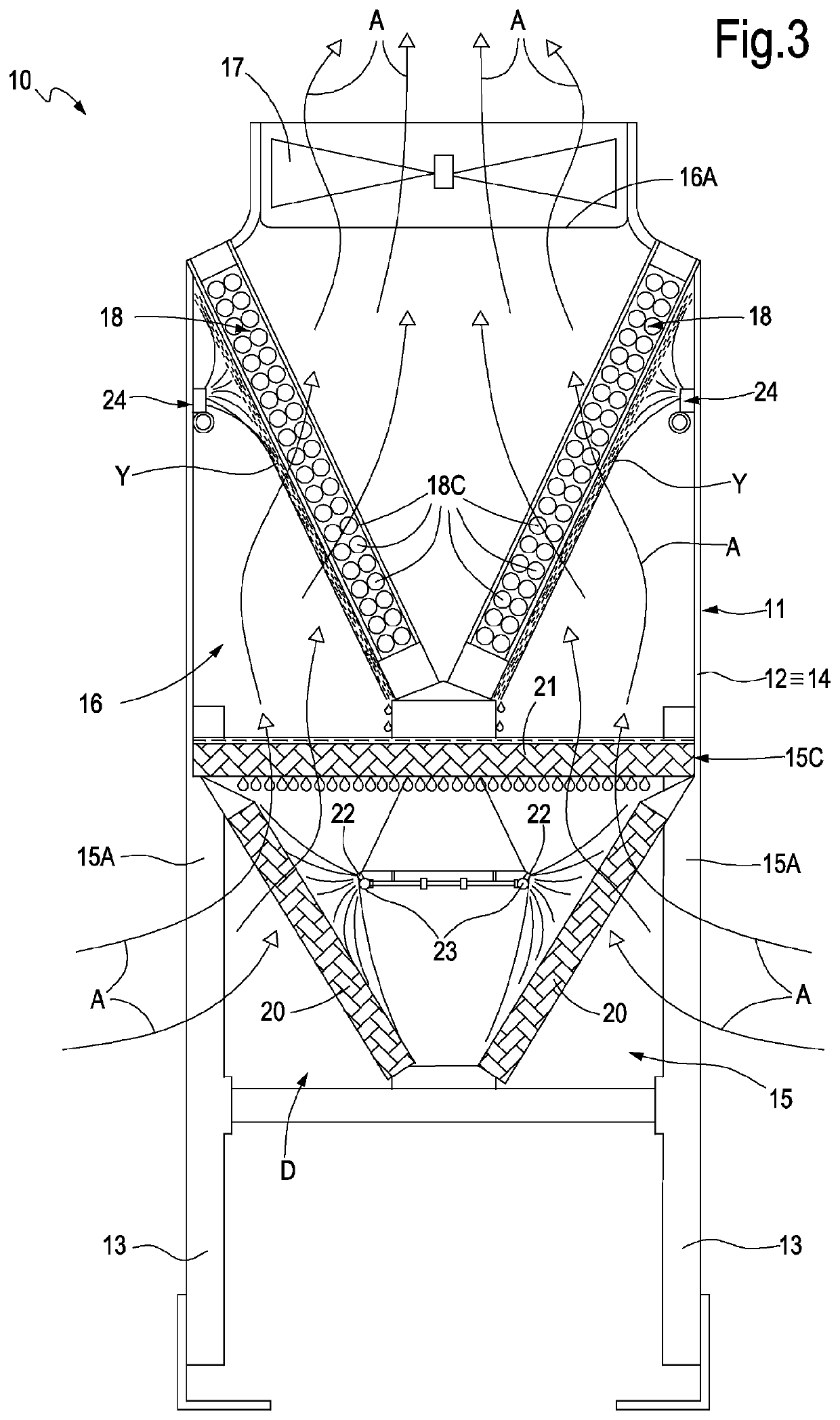

Method and device in particular for mashing in the production of beer

InactiveCN103237879AReduces problems with reduced heat transferImprove the mixing effectWort preparationStationary conduit assembliesThermodynamicsLiquid medium

The invention relates to a device and a method for heating a liquid medium, in particular a mashing device, having a vessel which can be filled and emptied, a heater for heating the liquid medium, in particular the mash, with a heating medium, a temperature sensor for measuring the flow temperature of the heating medium, a temperature sensor for measuring the return temperature of the heating medium, a temperature sensor for measuring the temperature of the liquid medium, a control unit for controlling a heating rate, wherein the control unit is constructed in such a manner and the heating rate is controlled in such a manner that the logarithmic temperature difference between the heating medium and the respective current temperature of the liquid medium is kept substantially constant.

Owner:KRONES AG

A kind of transparent environment-friendly PVC modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Method and device in particular for mashing in the production of beer

InactiveCN103237879BReduces problems with reduced heat transferImprove the mixing effectWort preparationStationary conduit assembliesLiquid mediumEngineering

The present invention relates to an apparatus and method for heating a liquid medium, in particular a brewhouse, the apparatus having: a container, which may be filled and emptied; a heater, which is used to heat a liquid medium using a heating medium, in particular malt syrup; a temperature sensor for measuring the flow temperature of a heating medium; a temperature sensor for measuring the return temperature of a heating medium; a temperature sensor for measuring the temperature of a liquid medium; a closed-loop control unit, which is used to control the heating rate in a closed loop, wherein the closed-loop control unit is constructed and closed-loop control of the heating rate in the following manner: the logarithmic temperature difference between the temperature of the heating medium and the corresponding current temperature of the liquid medium remains approximately constant.

Owner:KRONES AG

Combined convector

ActiveUS11365938B2Reduce water consumptionReduce the temperatureCorrosion preventionStationary conduit assembliesEngineeringMechanics

A convector for air cooling of a fluid flowing in a pipe, comprising: a path for a cooling air flow comprising an inlet from and an outlet towards the environment, a heat exchange section comprising at least one tube bundle defining a heat exchange surface, said section being provided in said path for the air flow, fan means producing said air flow along said path, so that said air flow externally invests said tube bundle on said; heat exchange surface, a humidifying section arranged in said path, upstream of said heat exchange section, where water is atomized to be invested by the air flow, characterized by comprising a wetting device for wetting directly with water a portion of the heat exchange surface of said tube bundle to further cool said portion of tube bundle.

Owner:FRIGEL FIRENZE SPA

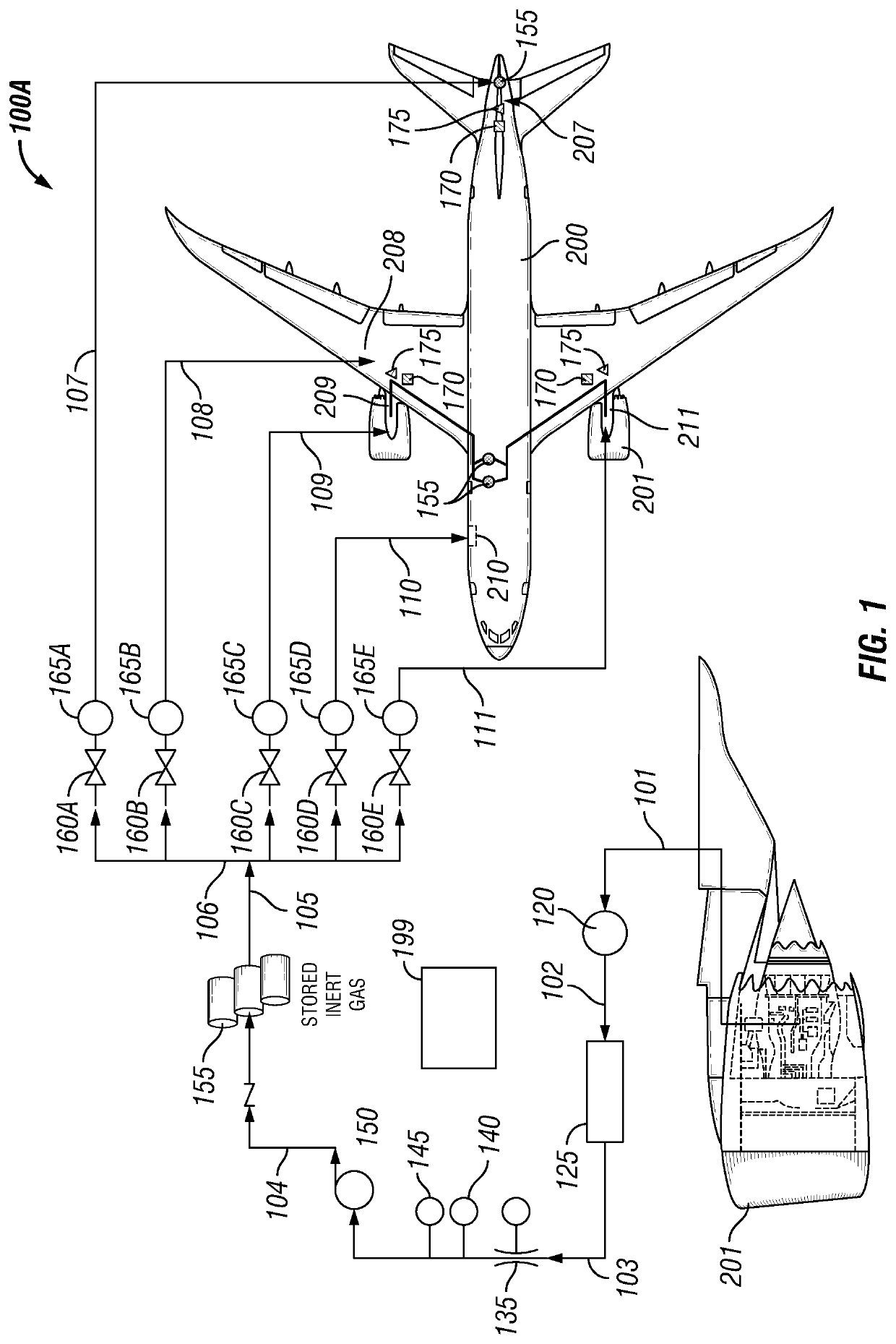

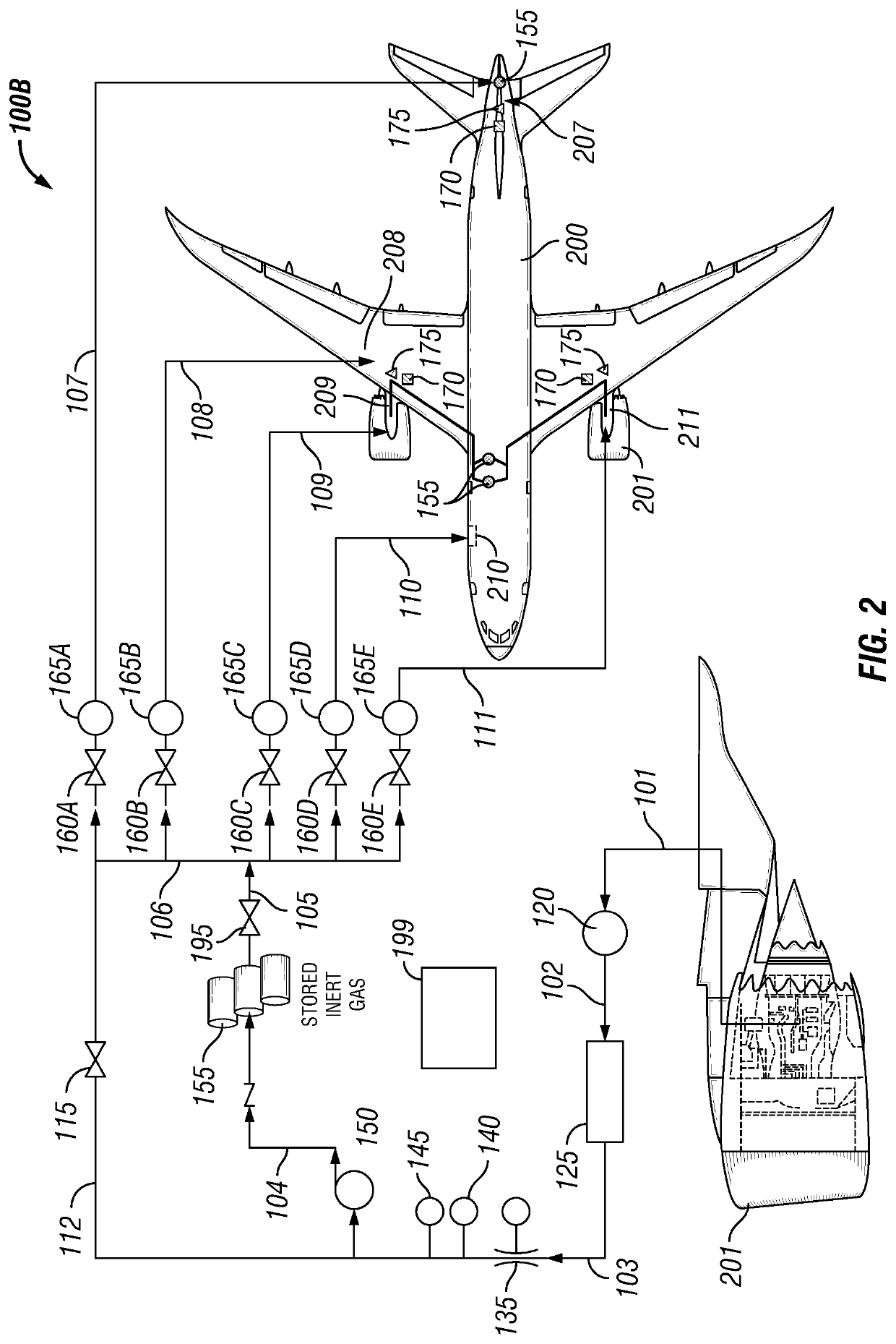

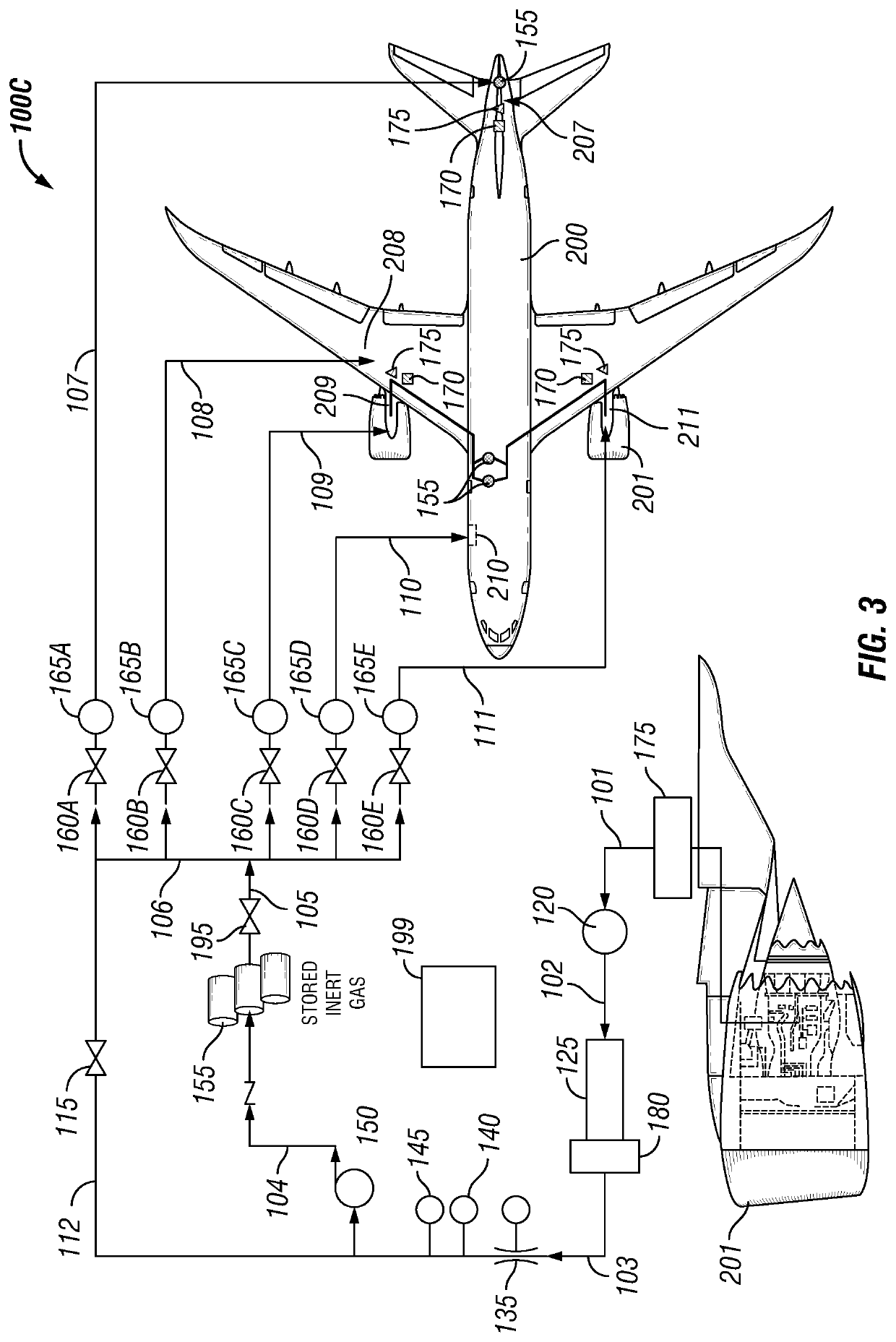

Inert Gas Fire Protection System

ActiveUS20200398093A1Lower flow temperatureFuel tank safety measuresFire rescueThermodynamicsFire protection

methods, apparatuses, and systems for harvesting inert gas exhausted from an engine and using the harvested inert gas to prevent an ignition event and / or extinguish an ignition event. The temperature of the harvested inert gas may need to be lowered. Unwanted components may be removed from the harvested inert gas. Combustion components may be completely burned from the harvested inert gas prior to providing the harvested inert gas to a fire protection system. The fire protection system uses the harvested inert gas to extinguish an ignition event and / or to provide a purge flow to prevent an ignition event. The fire protection system may be on an aircraft. Sensors may be used to detect an ignition event. Pressure sensors may be used to monitor the pressure of the harvested inert gas as well as to monitor the purge pressure of areas receiving a continuous purge flow of harvested inert gas.

Owner:THE BOEING CO

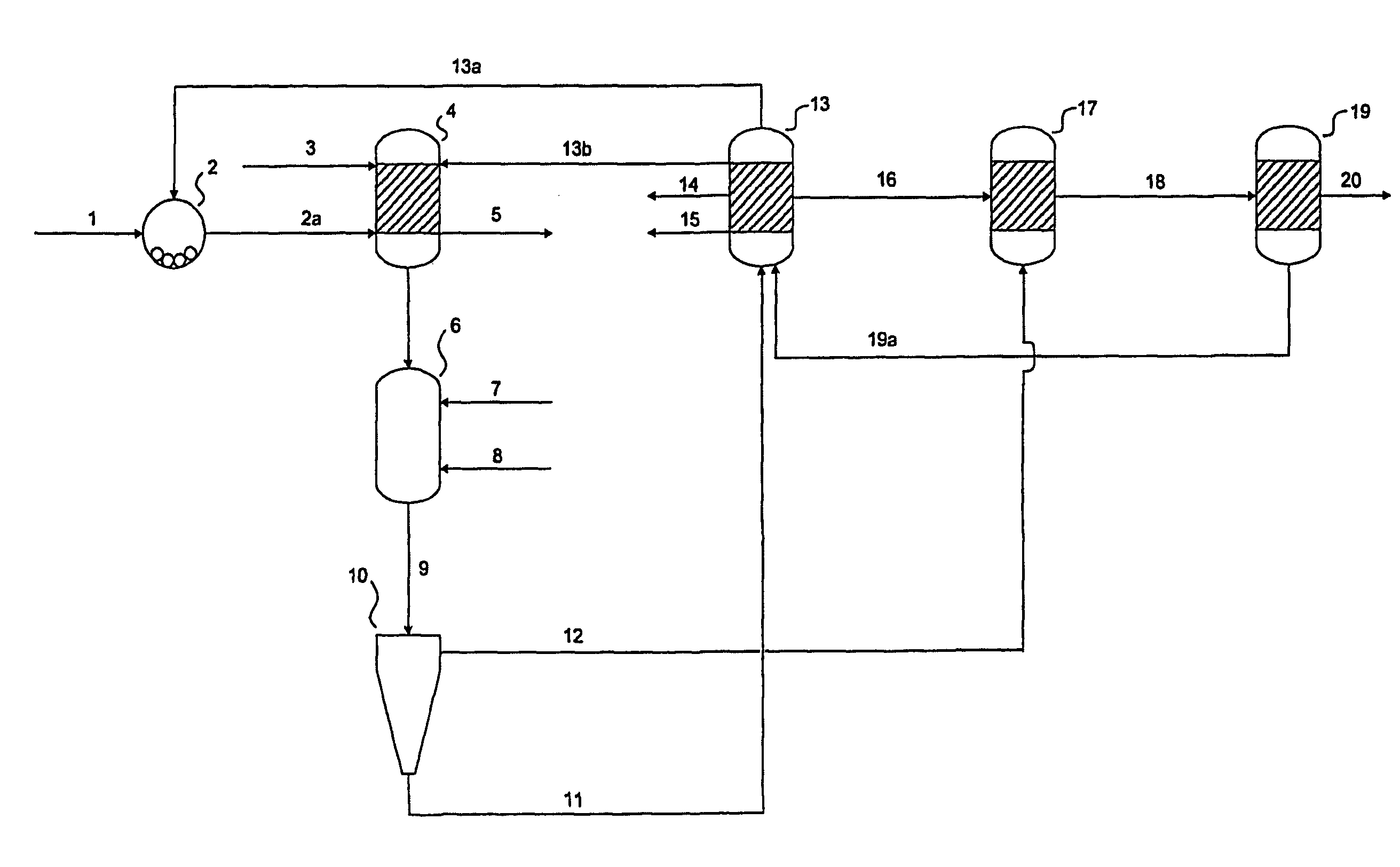

Process for the purification of crude gas from solids gasification

InactiveUS8529792B2Promote absorptionMinimising thermal lossGas purification by non-gaseous materials condensationGas contaminants removalAlkaline earth metalHalogen

A process and device is provided for the generation and purification of a crude gas for synthesis gas generation from a solid carbon-containing fuel by a coal gasification reaction. The fuel is mixed with a quenching medium directly after generation to dissipate the high internal energy and is then brought into contact with a solid basic alkaline earth metal compound or a sorbent consisting of a transition metal-containing compound just in the mixing chamber or downstream of the mixing chamber such that the acidic or basic or sulfur-containing or halogen-containing constituents contained in the crude gas and originating from the gasification reaction are absorbed. A solids-separating device downstream of the sorbent feed device removes the solid or solidified constituents from the system. The basic and transition metal-containing sorbent can be regenerated and returned to the process either in a mixture or after separation from the ash and slag constituents such that an energy-intensive cooling of the crude gas is not required for its purification and the synthesis gas thus purified can be used in a subsequent process without any further heating.

Owner:UHDE GMBH

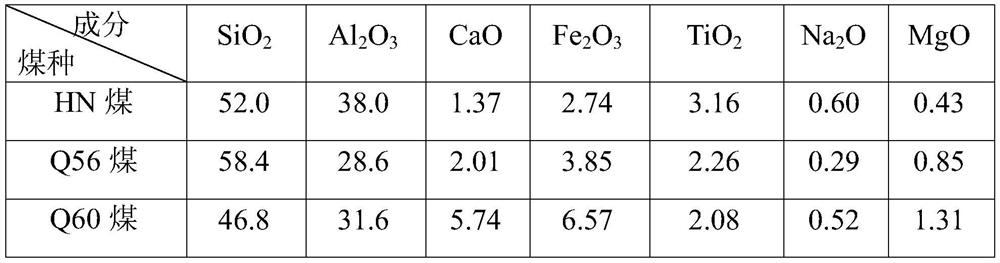

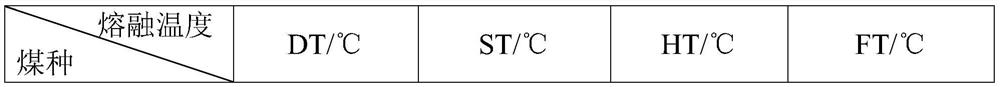

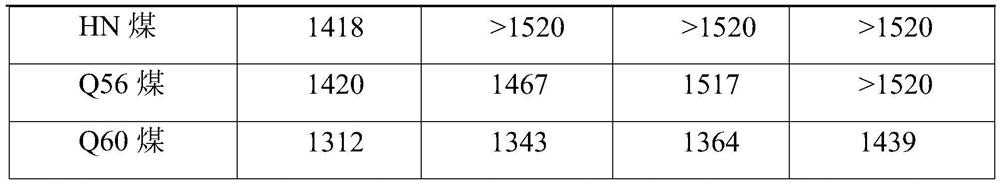

Composite flux for improving coal ash melting properties and its preparation method and application

ActiveCN109705918BLower flow temperatureGuaranteed operating temperatureGranular/pulverulent flues gasificationChemical compositionRed mud

A composite flux for improving coal ash melting properties, its preparation method and application. The composite flux is composed of CaO and red mud. The chemical composition and mass content of the composite flux are: 56.1%-90.6% for basic oxides and 9.4%-43.9% for acidic oxides. The composite flux provided by the present invention can not only effectively improve the melting characteristics of coal ash with high ash melting point, make it suitable for entrained bed gasification furnace with liquid slag discharge, but also realize resource utilization of polluted waste red mud, and has good economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temperature control of exhaust gas of a transportation refrigeration unit

ActiveUS10704438B2Reduce the temperatureLower flow temperatureInternal combustion piston enginesLighting and heating apparatusTemperature controlExhaust fumes

A transportation refrigeration unit includes an evaporator circulating a flow of refrigerant therethrough to cool a flow of supply air flowing over the evaporator, a compressor in fluid communication with the evaporator to compress the flow of refrigerant, and an engine operably connected to the compressor to drive operation of the compressor. The engine includes an exhaust pathway to direct an exhaust gas flow from the transportation refrigeration unit, and a nozzle extending circumferentially around the exhaust pathway defining a nozzle flowpath between the exhaust pathway and the nozzle, the nozzle configured to flow a cooling airflow along the nozzle flowpath to reduce a temperature of the exhaust gas flow.

Owner:CARRIER CORP

Normal-temperature turtle net crack repairing material and preparation method and application thereof

ActiveCN113956844AAchieving a solidified bondLower flow temperatureClimate change adaptationOil/fat/wax adhesivesRepair materialEngineering

The invention discloses a normal-temperature turtle net crack repairing material and a preparation method and application thereof, and belongs to the technical field of asphalt pavement maintenance and repairing materials. According to a treatment method in the prior art, the whole block of a disease part is generally cut and separated out of a pavement, the construction period is long, raw material preparation is complex, operation is tedious, the filling cost is high, or a repairing material needs to be heated at a high temperature on site, the requirement for the environment temperature is high, and permeability is poor. The material comprises 70-80% wt of an oil phase and 20-30% wt of water, and the oil phase comprises the following components in parts by weight: 70-80 parts of asphalt, 1-4 parts of span, 1-4 parts of a warm mix agent and 20-30 parts of diesel oil. The diesel oil is matched with the span and the warm mixing agent to improve the water melting capacity of the asphalt, and meanwhile, the asphalt can obtain good flowing capacity at normal temperature by utilizing the dilution effect of the diesel oil and water on the asphalt, so that the normal-temperature turtle net crack repairing material can be taken and used at normal temperature at any time, and the turtle net crack of an asphalt pavement is directly repaired.

Owner:淄博恒信路面材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com