A method for cooling air and devices

a technology of cooling gas and cooling air, applied in the direction of positive displacement liquid engine, lighting and heating apparatus, electric generator control, etc., can solve the problem of gas becoming colder as it accelerates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

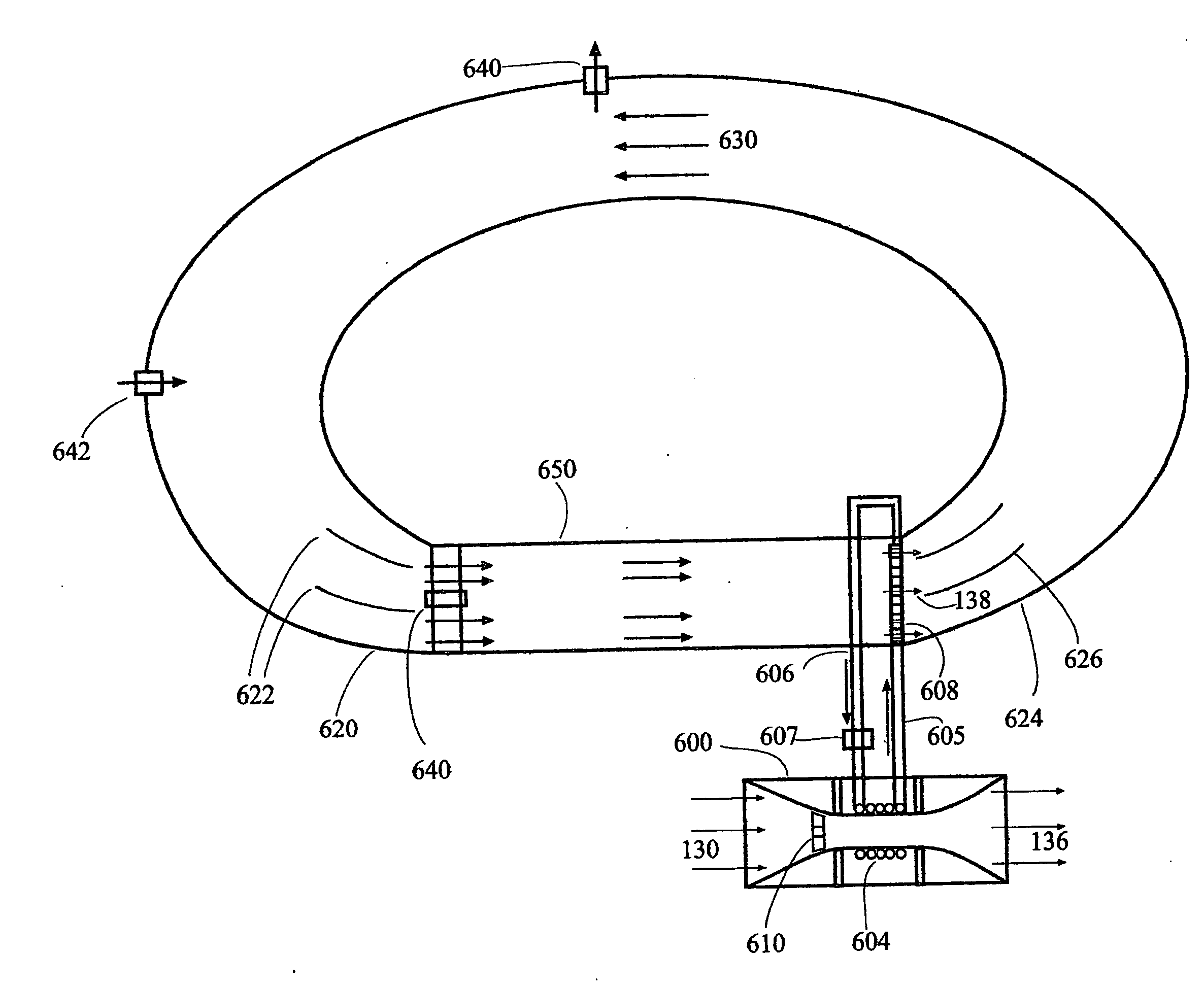

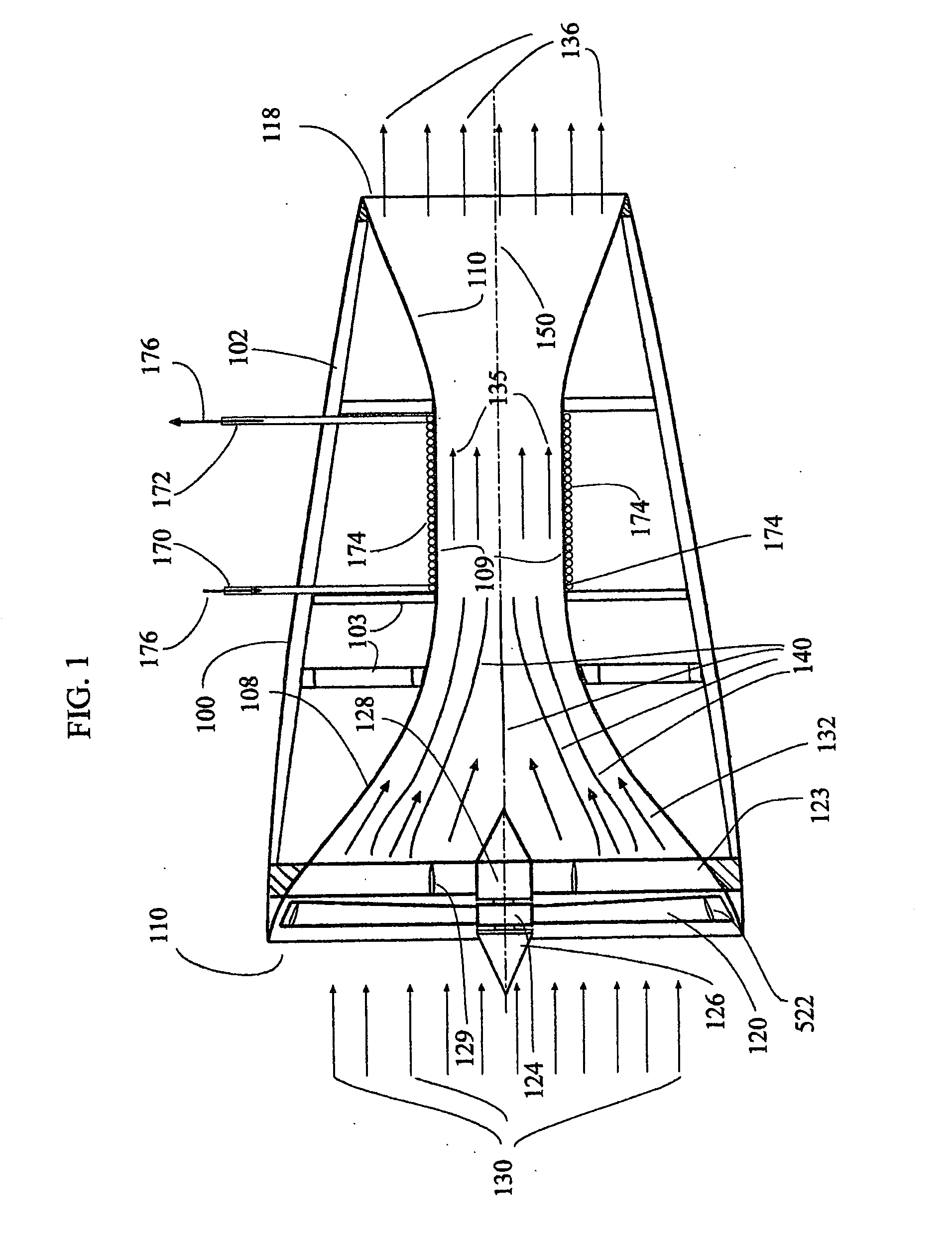

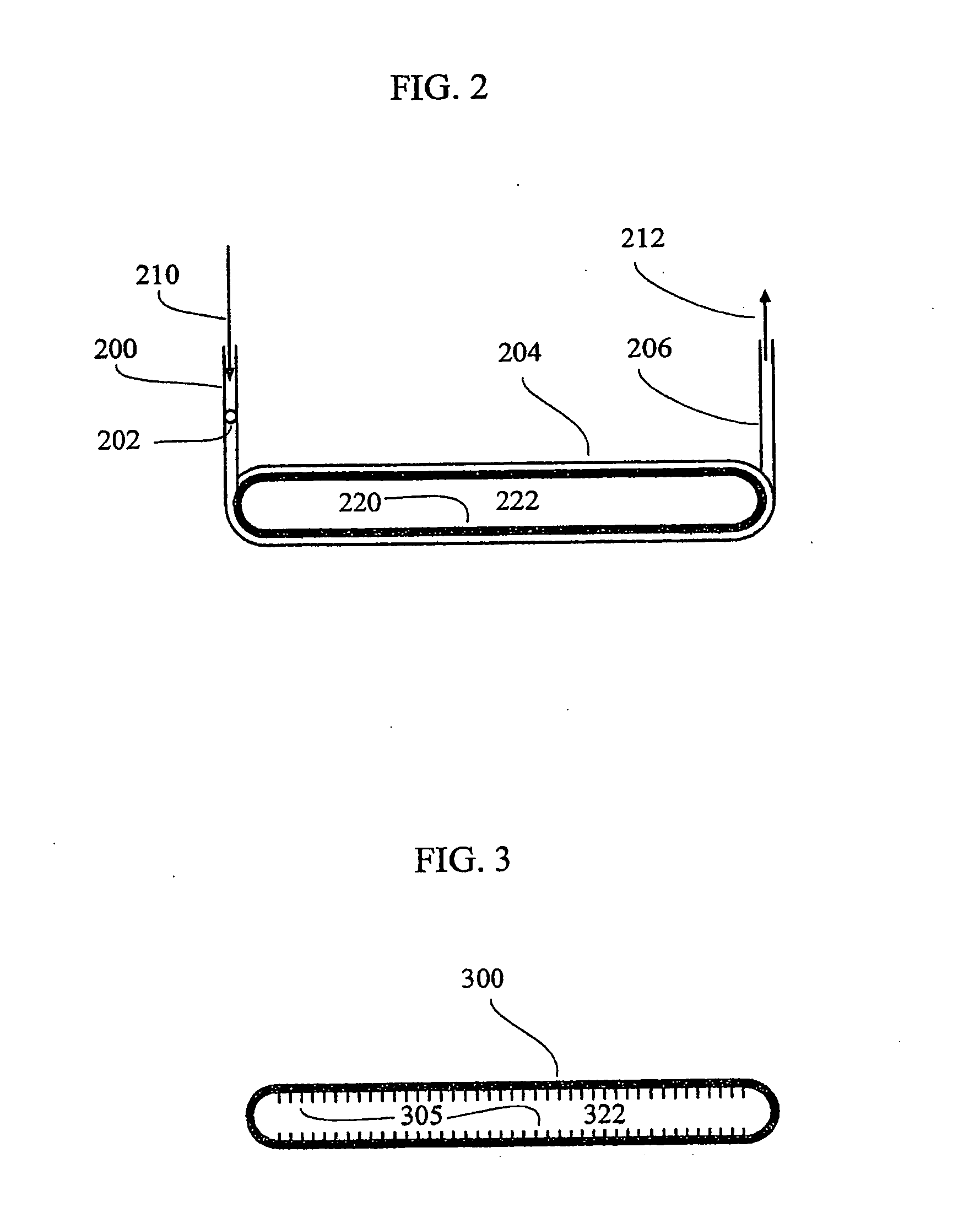

[0036]The invention disclosed here is a method and devices that use gas like air as a refrigerant for air-condition purposes. Due to the physical law of continuity, as the nozzle cross-section decreases the gas must accelerates. Thus the kinetic energy of the gas increases. In an adiabatic flow the kinetic energy comes on the expense of the gas internal energy CpT, where Cp is the gas constant pressure specific heat and T is the absolute temperature. At the nozzle throat, the gas has maximum speed and consequently minimum temperature. It is possible to use air at 50° Celsius and accelerate it to speed of sound at the throat, where its temperature will be: 0.834(273+50)° C.=269.4° K., i.,e., −3.8° C. This low temperature is good for air-condition system even it hottest countries in the world. The cold airflow cools the nozzle skin so we can use it to absorb heat from a heat exchanger and use the cooled flow within the heat exchanger to cool remote spaces or basically anything. The us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com