Composite flux for improving coal ash melting properties and its preparation method and application

A technology of flux and characteristics, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of poor melting of coal ash with high ash melting point, and achieve excellent flux effect, improved melting characteristics, good economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

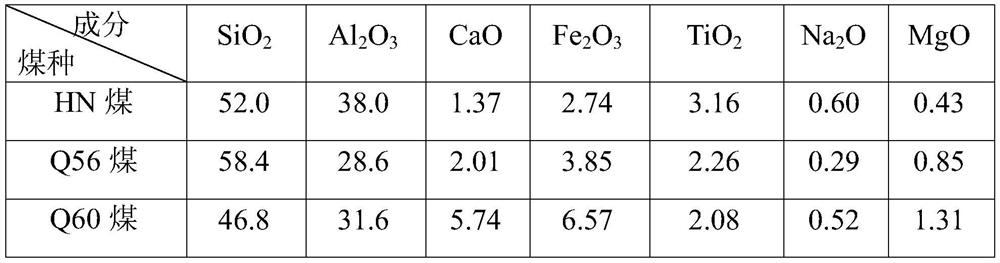

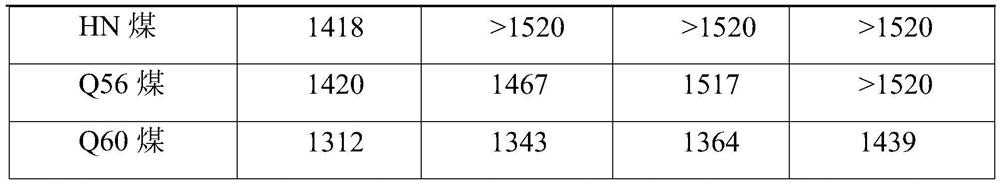

Method used

Image

Examples

Embodiment 1

[0024] According to the mass ratio, CaO and Bayer process red mud are mixed evenly in the ratio of 2:1 to make a composite flux, and then added to the high ash melting point coal at 2-6% of the mass content of the coal base, ground and mixed evenly. The mass content of basic oxides (CaO, Fe 2 o 3 and Na 2 The mass content of O) is 82.5%, and the balance is acidic oxide. The mass content of CaO in the composite flux is 68.9%, Fe 2 o 3 The mass content is 9.3%, Al 2 o 3 The mass content is 8.4%, TiO 2 The mass content is 1.5%.

Embodiment 2

[0026] Mix CaO and Bayer process red mud uniformly at a ratio of 1:1 according to the mass ratio to make a composite flux, then add 2-6% of the mass content of the coal base to the high ash melting point coal, grind and mix uniformly. The mass content of basic oxides (CaO, Fe 2 o 3 and Na 2 The mass content of O) is 73.4%, and the balance is acidic oxide. The mass content of CaO in the composite flux is 52.8%, Fe 2 o 3 The mass content is 14.1%, Al 2 o 3 The mass content is 12.7%, TiO 2 The mass content is 2.3%.

Embodiment 3

[0028] Mix CaO and Bayer red mud at a ratio of 1:2 according to the mass ratio to make a composite flux, and then add 2 to 6% of the mass content of the coal base to the high ash melting point coal, grind and mix evenly. The mass content of basic oxides (CaO, Fe 2 o 3 and Na 2 The mass content of O) is 64.4%, and the balance is acidic oxides. The mass content of CaO in the composite flux is 36.8%, Fe 2 o 3 The mass content is 19.0%, Al 2 o 3 The mass content is 17.1%, TiO 2 The mass content is 3.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com