[0030]Rather than using a capillary tube metering mechanism for feeding refrigerant fluid into the refrigerant evaporator, such as is normally used for smaller

refrigeration systems, the device according to the present invention, may be fitted with an automatic suction valve so as to allow for the device to adapt to varying loads created by different environments. One object is that the

condensation process is to provide efficient

processing of atmospheric, that is

ambient air. Thus the intake air flow downstream of the

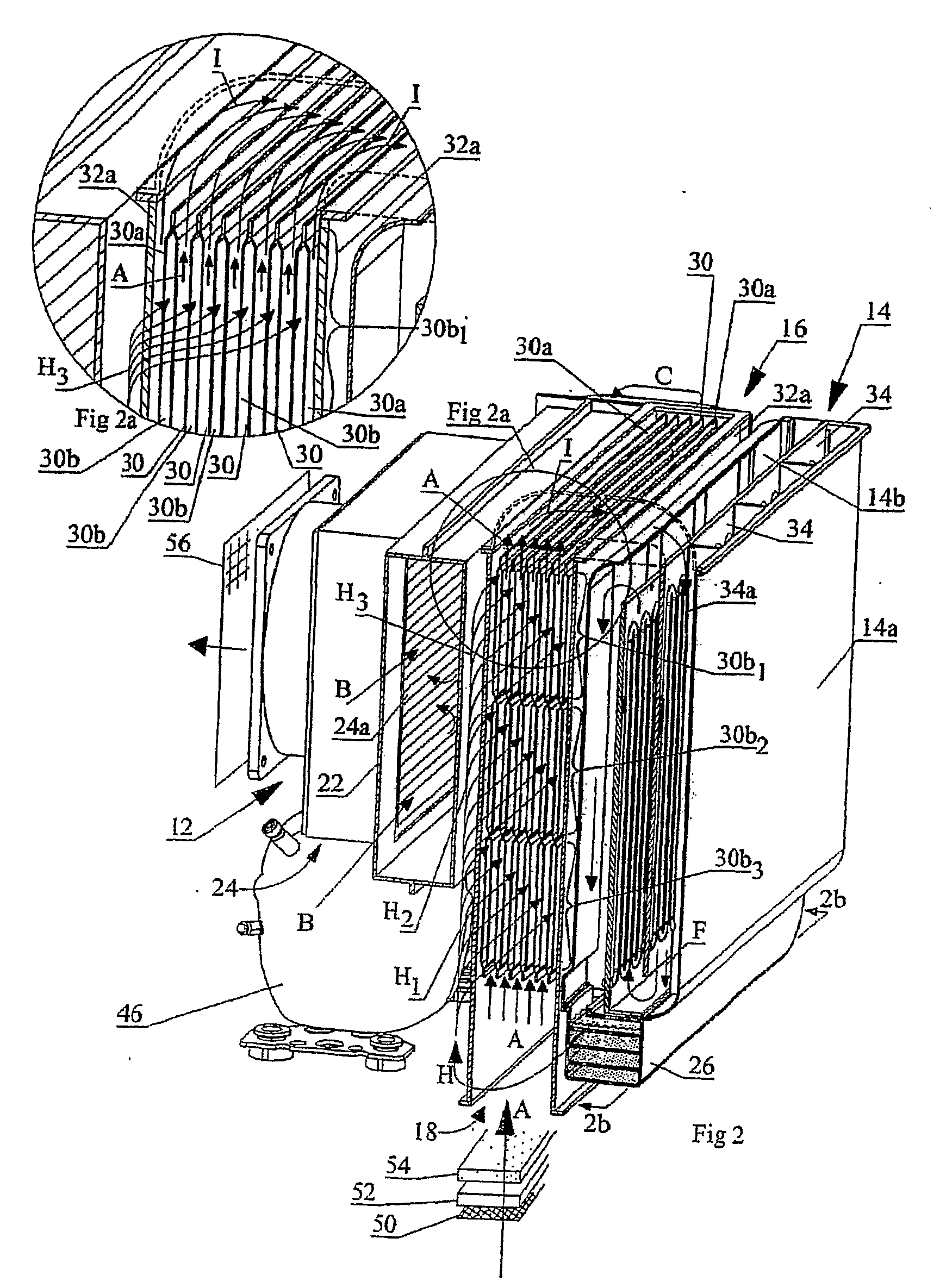

air filtration may be pre-cooled, prior to entering a refrigerant evaporator used to condense moisture out of the intake air flow, by passing the intake air flow through an air-to-air beat exchanger, itself cooled by cooled air leaving the evaporator. That is, the incoming air flow is cooled before it enters the refrigerant evaporator section by passing it in close proximity in the heat exchanger to the cooled air that is leaving the refrigerant evaporator. Air-to-air heat exchangers may be constructed to be very efficient, reaching 80% efficiency, and therefore reducing the temperature of the incoming air flow towards the

dew point prior to the air flow entering the refrigerant evaporator, reduces the temperature differential, or

temperature drop that must obtained by passing the air over cooled surfaces in the refrigerant evaporator to obtain the

dew point temperature, and thus may have a significant

impact upon the efficiency of the

condensation process and thus the efficiency of the device. For example the device may thus be optimized to increase the air flow rate and still be able to reduce the air flow temperature to the

dew point, or the device will be able to

handle very hot inflow temperatures and still reduce the dew point temperature of a reasonable air flow volume over time so as to harvest a useful amount of moisture. Sensors provide temperature, for example ambient, inlet temperatures, refrigerant evaporator inlet and refrigerant evaporator outlet temperatures,

humidity, and fan speed or other air flow rate indicators to the process to optimize and balance those variables to maximize harvested moisture volume. Embodiments of the present invention may thus include varying the flow of air through the system such that the device has a prescribed amount of air passing through the refrigerant evaporator and a different flow of air passing through the refrigerant condenser of the corresponding refrigerant circuit, allowing for optimized function.

[0031]In addition to the benefits described above, the water condenser may add additional value in further

processing. For example, the harvested water may be further processed so as to increase the value of the water, by adding back inorganic minerals missing or only present in small amounts in the water, so as to accommodate the perceived value of these minerals to the

consumer. This process may also add organic minerals back into the water which are of benefit to the

human body, rather than simply adding back inorganic minerals that the

human body may not be able to properly assimilate.

[0037]The already pre-cooled primary air flow is further cooled in the first

refrigeration unit below a dew point of the primary air flow so as to commence condensation of moisture in the primary air flow onto the refrigerated surfaces for gravity-assisted collection of the moisture into a moisture collector, for example a drip late or pan mounted under or in a lower part of the housing. The downstream end of the first

refrigeration unit cooperates with, for passage of the primary air flow into, an upstream end of the post-refrigeration set of air conduits, for example to then enter the air-to-air heat exchanger so as to pre-cool the primary air flow before the primary air flow engages the first refrigeration unit. Because of pre-cooling by the heat exchanger, condensate may be collected with minimal power requirements. A second air-to-air heat exchanger may further increase system performance. Collectively the pre-refrigeration and post-refrigeration sets of air conduits form the first cooling stage, and collectively the plate or plates of the refrigerant evaporator form the second cooling stage.

[0042]The air flow

prime mover may be selectively controllable and the processor may regulate the primary, auxiliary or combined air flow so as to minimize the

air temperature of the primary air flow from dropping too far below the dew point for the primary air flow to minimize condensation within the heat exchanger, and so as to optimize or maximize the volume of

moisture condensation in the refrigeration unit.

Login to View More

Login to View More  Login to View More

Login to View More