Method and device in particular for mashing in the production of beer

A device, especially a technology, applied in the fields of biochemical equipment and methods, beer brewing, lighting and heating equipment, etc., can solve problems such as slow heating rate control, achieve high filling height, increase volume flow, and large barrel diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

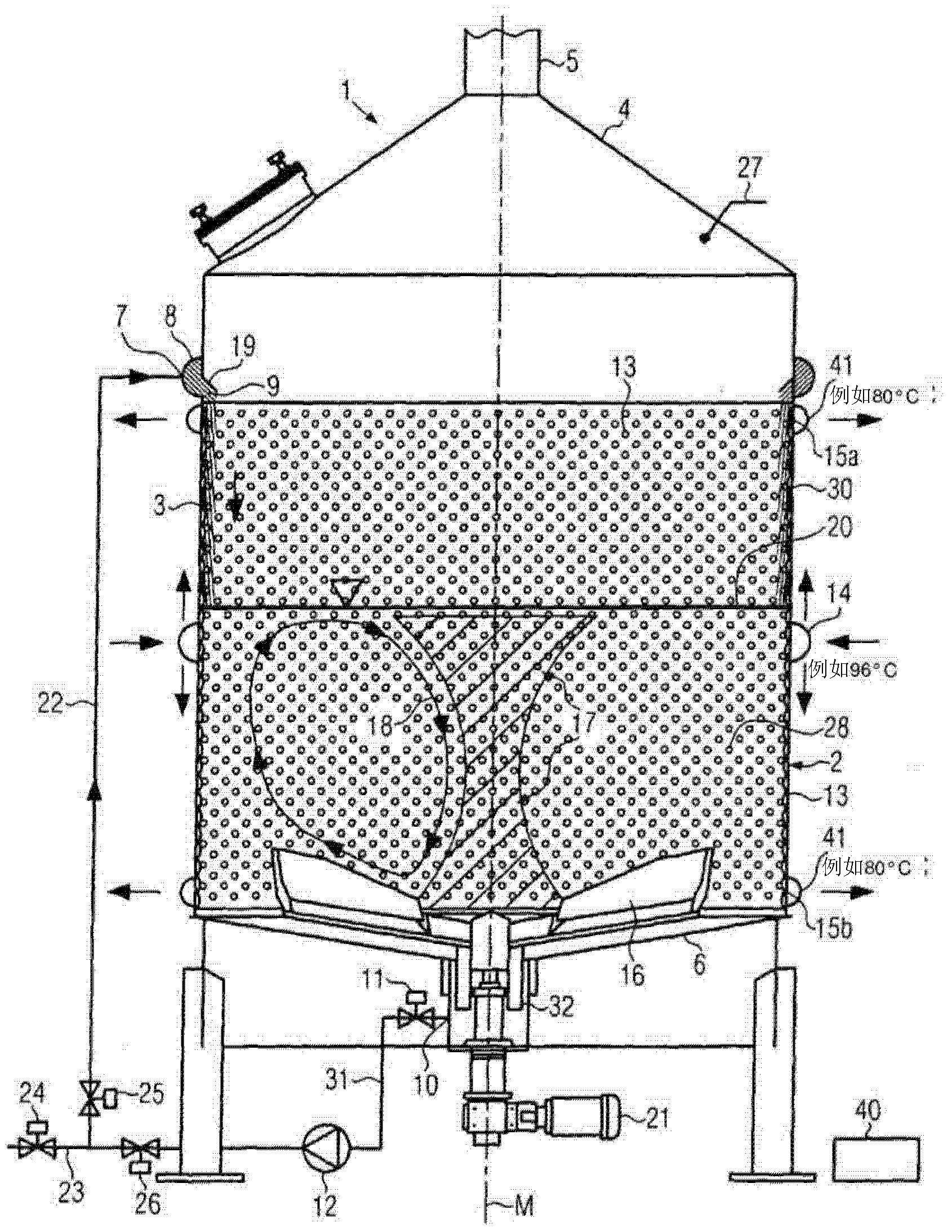

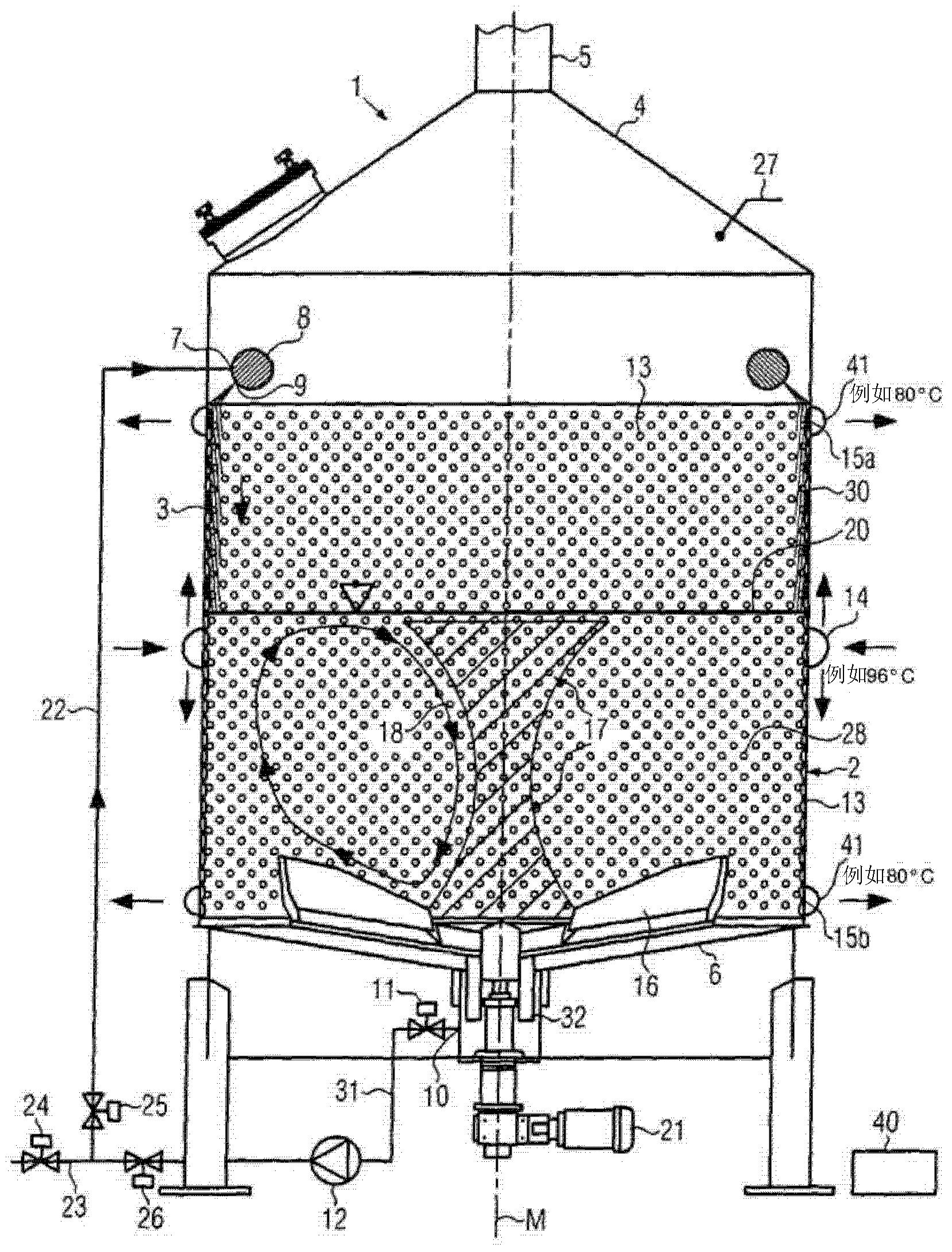

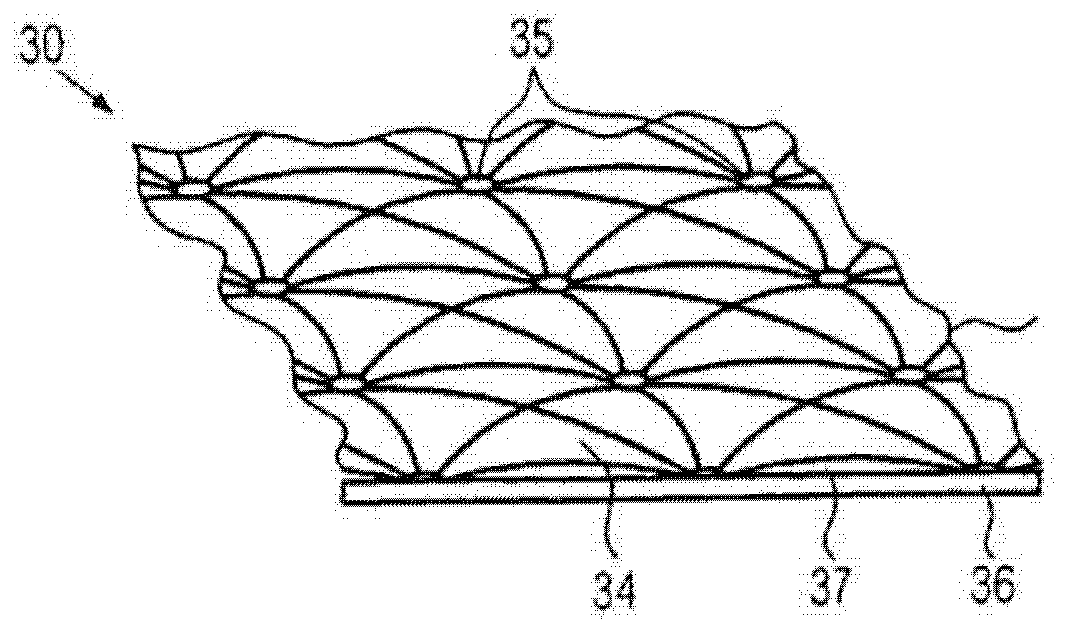

[0040] Figure 7 The basic configuration of the embodiment according to the present invention is shown. Combine below Figure 1 to Figure 5 A more detailed description of the equipment used to heat the liquid medium, especially the saccharification equipment. However, basically, the device has a container 2, an outlet 10 for the liquid medium, and a heater 30, where the heater 30 is in the form of a frame heater, and the liquid medium is heated along the heating surface 13 of the heater 30. The heater has upper and lower outlets 15 (RET) for heating medium and an inlet 14 arranged between the upper and lower outlets. The corresponding bottom heater can also be set. The heater operates according to the heat exchanger principle. The liquid medium is heated at a specific heating rate.

[0041] For closed-loop control of the heating rate, the temperature sensor 105 is provided to measure the temperature of the liquid medium in the container 2. In addition, the temperature sensor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com