Rubber roller device of grain huller

A technology of rubber rollers and huskers, applied in grain processing, grain pod removal, grain shelling, etc., can solve the problems of rubber rollers falling off, affecting production safety and production efficiency, etc., to avoid rubber rollers falling off and easy disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

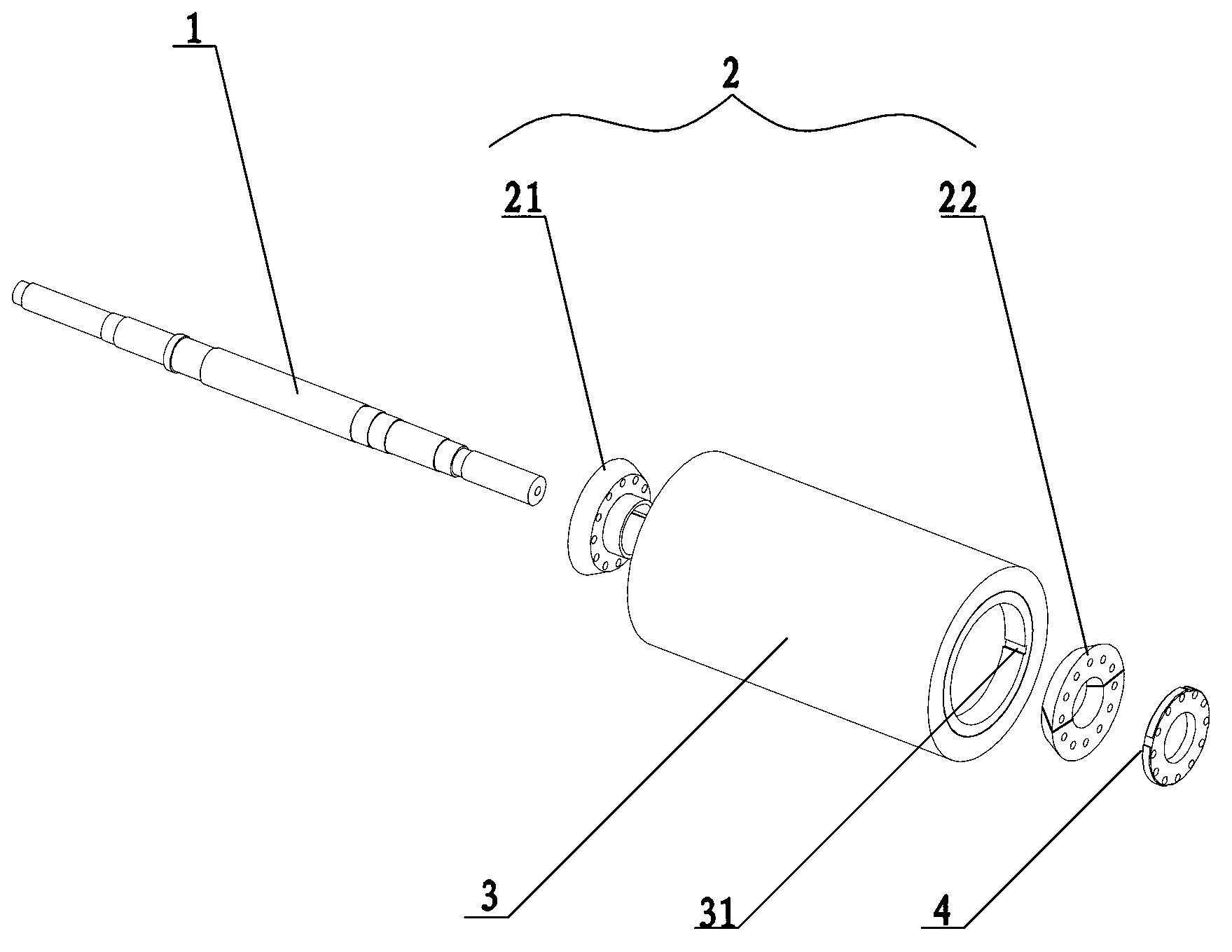

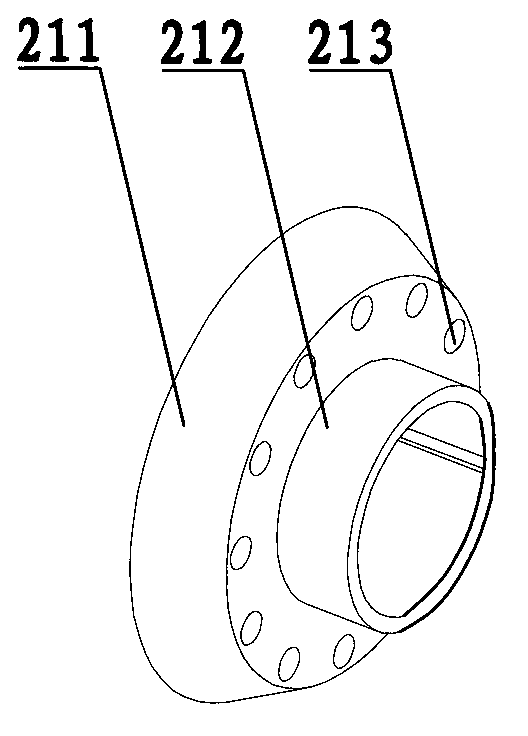

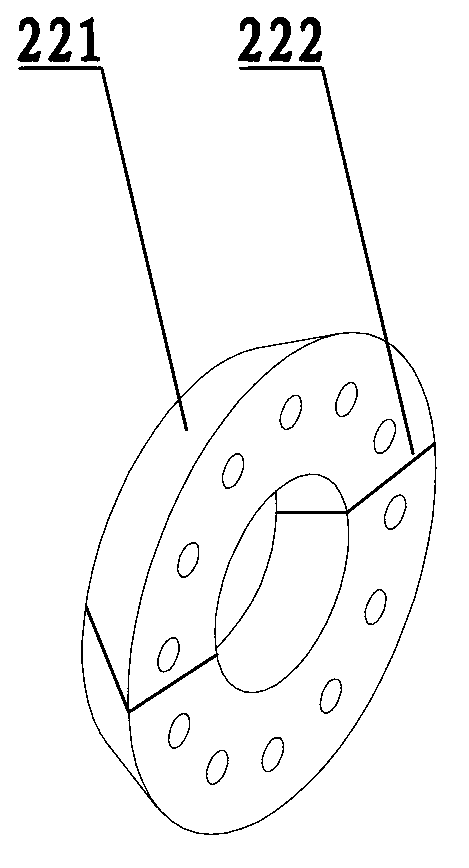

[0018] A kind of rubber roller device of the rice huller of the present invention, combines figure 1 , including the main shaft 1, rubber roller 3 and nut 4, the two ends of the rubber roller 3 are installed on the main shaft 1 through the nut 4, the rubber roller 3 is installed on the frame of the rice huller through the main shaft 1, and at the end of the rubber roller 3 There is also a pair of parallel caps 2 between the nut 4, a groove 31 is provided on the inner side of the rubber roller 3, and the parallel cap 2 and the rubber roller 3 are installed together, and the rubber roller 3 is fixed on the main shaft 1 together with the nut 4 . Wherein, the parallel cap 2 is bowl-shaped, including a first parallel cap 21 and a second parallel cap 22 used in conjunction, the first parallel cap 21 is set on the main shaft 1, the second parallel cap 22 is installed on the end of the main shaft 1, and the second parallel cap 22 is mounted on the main shaft 1. One cap 21 includes a ...

Embodiment 2

[0021] The arrangement and working principle of this embodiment are the same as those of Embodiment 1, the difference is that there is one circlip 222 , and the circlip 222 and the groove 31 of the rubber roller 3 form a tightening device for fixing the rubber roller 3 .

Embodiment 3

[0023] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that there are three snap springs 222, which are evenly arranged on the surface of the bowl part two 211 along the second parallel cap 22, and one of them is buckled on the bottom of the rubber roller 3 In the groove 3, the other two are matched with the snap rings buckled in the groove 31, and the three snap rings form a structure for fixing the rubber roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com