Heating medium furnace for long-distance-delivery crude oil pipeline

A heat medium furnace and crude oil technology, which is applied in the field of heating furnaces, can solve the problems of hidden dangers in the safe operation of heating furnaces, frequent maintenance of heating furnaces, and increased workload of maintenance personnel, so as to improve thermal efficiency of operation, improve atomization effect, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

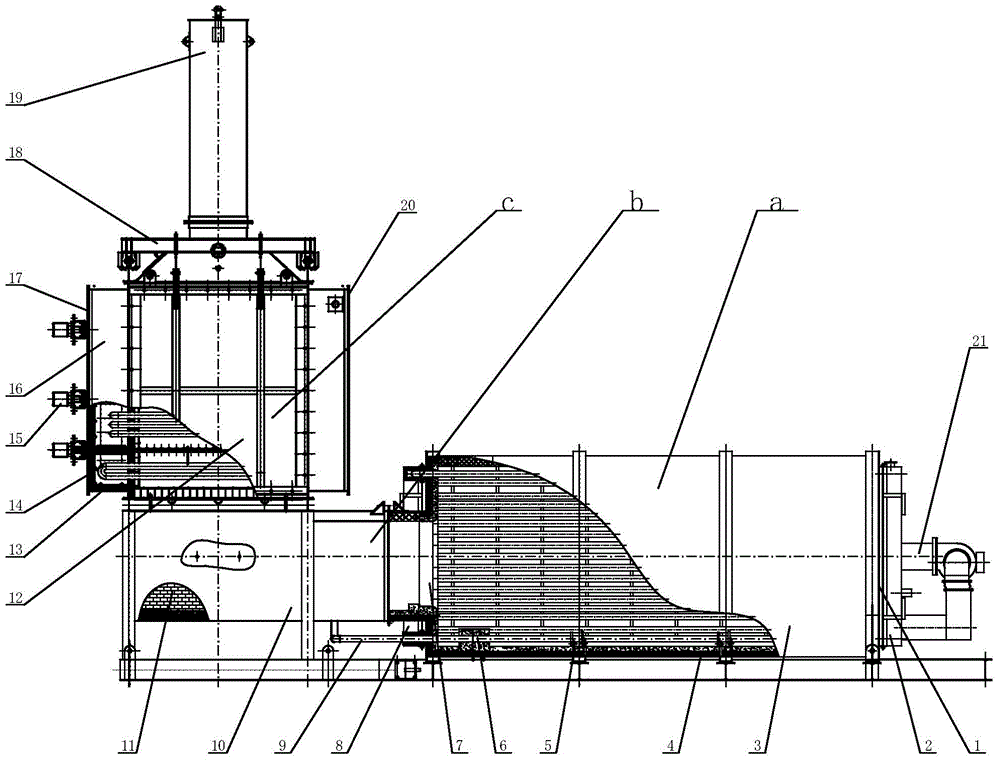

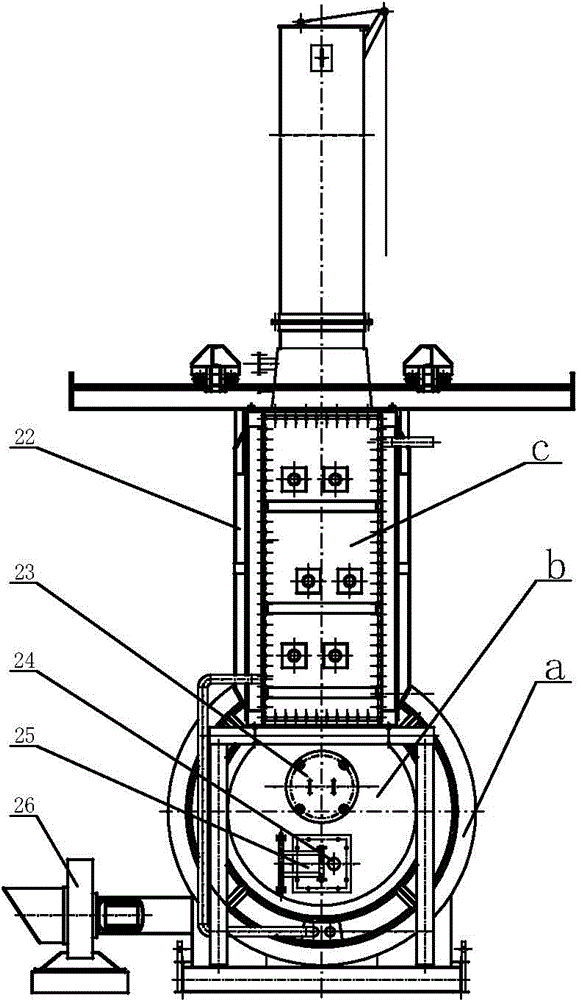

[0023] Such as figure 1 with figure 2 As shown, a heat medium furnace for a long-distance crude oil pipeline, the heating medium is a heat medium, which includes a radiation chamber a, a convection chamber c, and a transition section b connecting the radiation chamber a and the convection chamber c; one side of the radiation chamber a is installed There is a burner 21, a convection chamber soot blowing system 15 is installed on one side of the convection chamber c, and a chimney 19 is arranged at the upper end of the convection chamber c.

[0024] The radiation chamber a is used as the main combustion place. The radiation chamber a includes a cylindrical radiation chamber steel structure 3 and a radiation chamber front wall 1 and a radiation chamber rear wall 7 fixed at both ends of the radiation chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com