Temperature control system in catalyst production device, temperature control method and application of temperature control system

A technology of temperature control system and production device, applied in the direction of temperature control, control/regulation system, catalyst activation/preparation, etc., can solve the problems of large temperature fluctuation, hysteresis, adverse effects on product performance and quality of maleic anhydride catalyst, etc. The effect of quality improvement, overcoming large temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

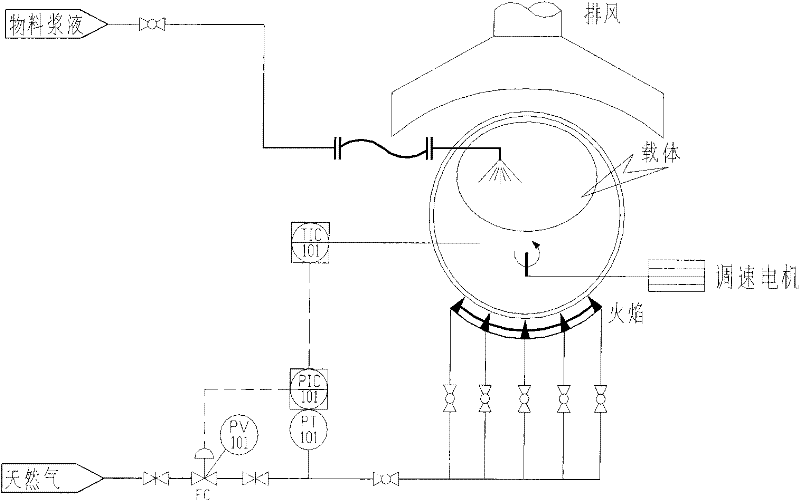

[0071] The implementation of the temperature and pressure cascade control method in the maleic anhydride catalyst preparation process mainly includes the following steps:

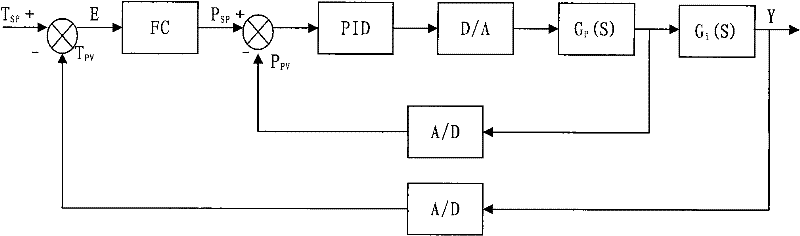

[0072] (1) The control method in the process is changed from temperature single-loop control to temperature and pressure cascade control. Through the programming configuration of the engineer station and the PLC control system, the pressure of the natural gas is controlled by the temperature of the sugar coating pan, and then the flow of the natural gas is adjusted. Among them, the temperature loop is the main loop, and the pressure loop is the secondary loop to directly control the flow of natural gas. On-site commissioning determines the initial PID parameters of the main and auxiliary loops.

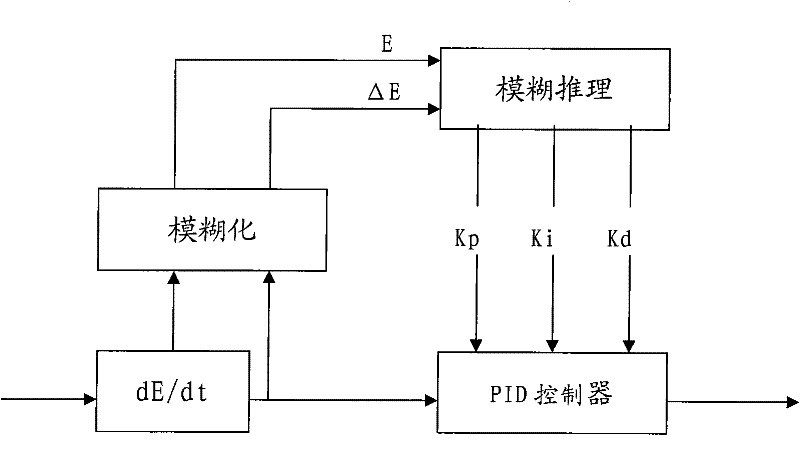

[0073] (2) In the temperature control, a PID fuzzy controller is designed to transform the temperature deviation and the rate of change of the deviation into the corresponding basic domain, and the temperature dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com