Silicon-based/graphene nanobelt composite material with high capacity and high cycle efficiency and preparation method thereof

A technology of graphene nanobelts and composite materials, applied in the direction of graphene, nanotechnology for materials and surface science, nanocarbon, etc., which can solve the problems of insufficient charge and discharge performance, high cost, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

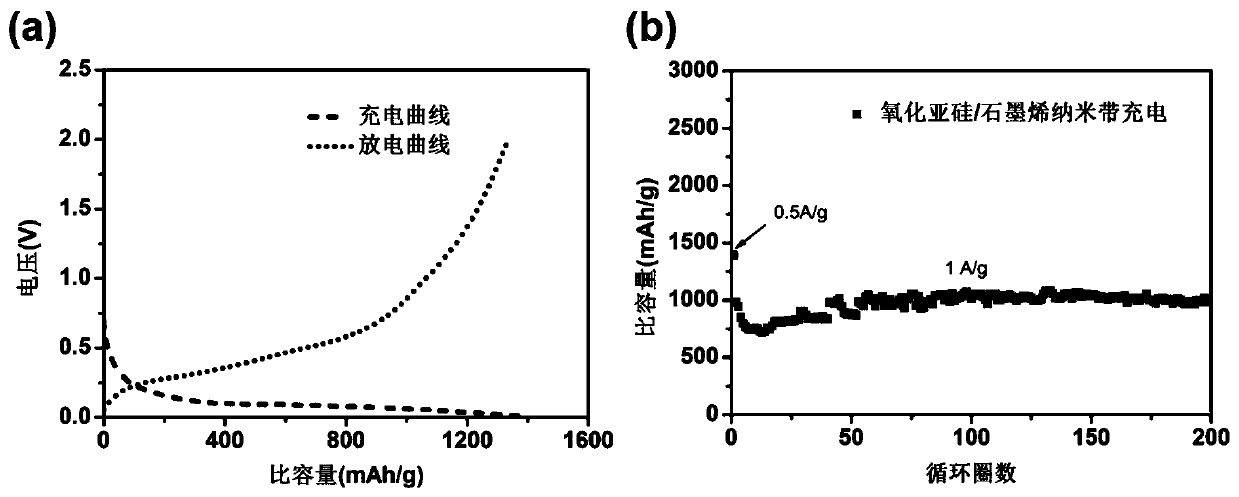

[0075] A silicon-based / graphene nanoribbon composite material with high capacity and high cycle efficiency, each component and its mass percentage are:

[0076] Nano silicon 87%

[0077] Graphene Nanoribbons 10%

[0078] Lithium 3%

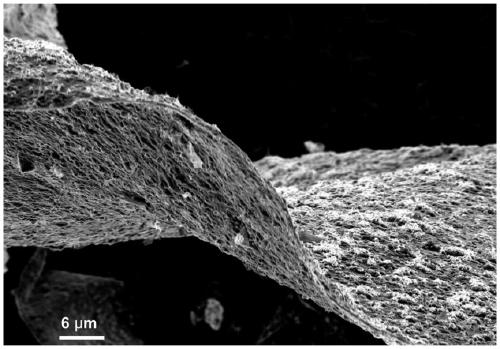

[0079] Among them, the average particle size of nano-silicon is 10nm, and the specific surface area is 120m 2 g -1 , the pore volume is 0.81cm 3 g -1 ; The graphene nanoribbon has a diameter of 5 nm, a length of 10 μm, and a carbon content of 95%.

[0080] A method for preparing a silicon-based / graphene nanoribbon composite material with high capacity and high cycle efficiency, the specific steps are as follows:

[0081] (1) Preparation of nano silicon suspension

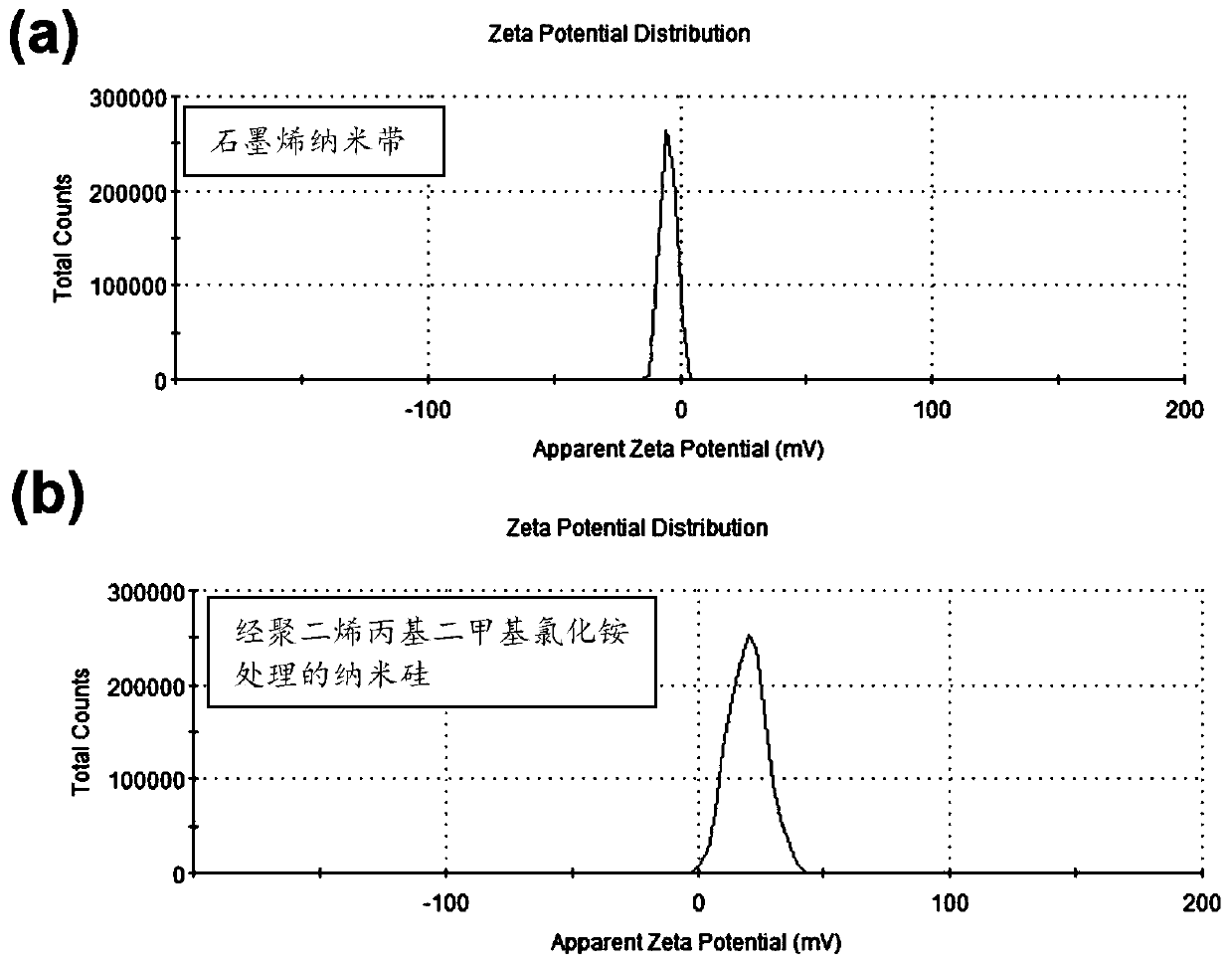

[0082] Nano-silicon / polydiallyldimethylammonium chloride / deionized water were mixed and stirred according to the ratio of 1g:0.1g:1000mL for 240min to prepare a positively charged nano-silicon suspension.

[0083] (2) Preparation of nano-silicon / graphene nanoribbon composites

...

Embodiment 2

[0088] A silicon-based / graphene nanoribbon composite material with high capacity and high cycle efficiency, each component and its mass percentage are:

[0090] Graphene Nanoribbons 30%

[0091] Lithium 6%

[0092]Among them, the average particle size of silicon oxide is 300nm, and the specific surface area is 50m 2 g -1 , the pore volume is 0.25cm 3 g -1 ; The graphene nanoribbon has a diameter of 10 nm, a length of 30 μm, and a carbon content of 98%.

[0093] A kind of preparation method of silicon base / graphene nanoribbon composite material with high capacity and high cycle efficiency is the same as embodiment 1, and the difference with embodiment 1 is:

[0094] In step (1), silicon oxide / hexadecyltrimethylammonium bromide / deionized water were mixed and stirred according to the ratio of 1g:0.5g:100mL for 240min;

[0095] In step (2), the graphene nanoribbons were ultrasonically dispersed for 3 hours, the concentration was 3mol / L, the mass r...

Embodiment 3

[0098] A silicon-based / graphene nanoribbon composite material with high capacity and high cycle efficiency, each component and its mass percentage are:

[0099] Porous silicon 10%

[0100] Graphene Nanoribbons 89%

[0101] Lithium element 1%

[0102] Among them, the average particle size of porous silicon is 30μm, and the specific surface area is 200m 2 g -1 , the pore volume is 1.5cm 3 g -1 ; The graphene nanobelt has a diameter of 50nm, a length of 60μm, and a carbon content of 99%.

[0103] A kind of preparation method of silicon base / graphene nanoribbon composite material with high capacity and high cycle efficiency is the same as embodiment 1, and the difference with embodiment 1 is:

[0104] In step (1), the silicon-aluminum alloy with a silicon content of 20% is used as a raw material, added to a 0.5 mol / L hydrochloric acid solution and stirred for 24 hours, and then dried at 60°C for 10 hours after centrifugation to obtain a porous silicon powder. Alkyl dimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com