Manufacture method of soft clad door

A production method and technology of soft-packed doors, which are applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of tearing, peeling off of the surface cortex, and low bonding strength between the cortex and MDF, etc. Achieve the effect of improving bonding force, overcoming shedding, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

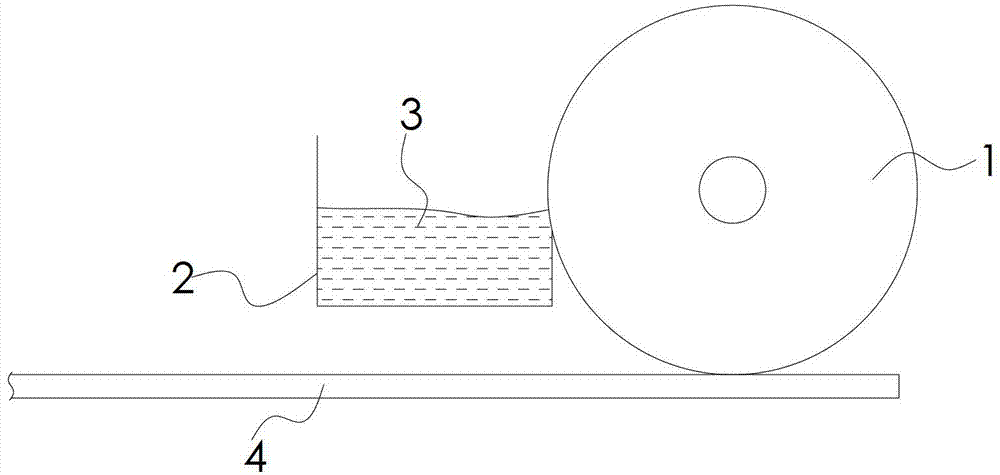

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

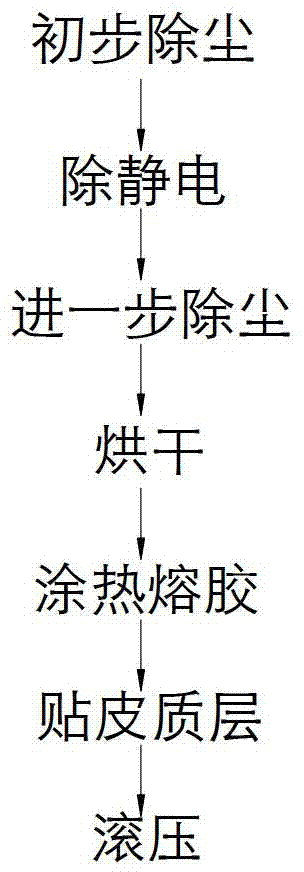

[0025] see figure 1 The manufacturing method of the soft bag door of the present invention comprises the following steps:

[0026] A. Perform preliminary dust removal treatment on the surface of the MDF. During the process, use the conveyor belt to transport the MDF, and set a cleaning roller with a brush above the conveyor belt. The motor drives the cleaning roller to rotate. Dust and other sundries on the fiberboard;

[0027] B. Use the conveyor belt to transport the MDF to the static removal station, use the motor to drive the static removal roller with the brush to rotate, and the brush to contact the surface of the MDF to remove the static electricity carried by the MDF;

[0028] C. Transport the MDF to the dedusting room. The top of the dedusting room is equipped with an exhaust fan located on the top of the MDF. Start the exhaust fan to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com