Solenoid directional valve and push rod and armature structure thereof

A technology of electromagnetic reversing valve and push rod, which is applied in the direction of valve details, multi-way valves, valve devices, etc., and can solve problems such as reducing product reliability, qualitative changes of push rod and armature, and affecting the normal operation of electromagnetic reversing valves. Achieve the effect of overcoming cracking and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

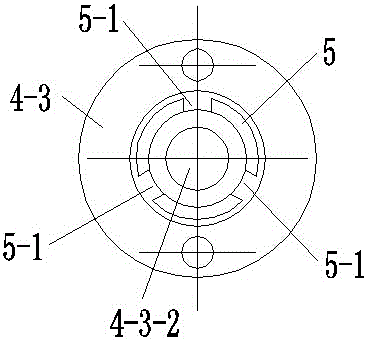

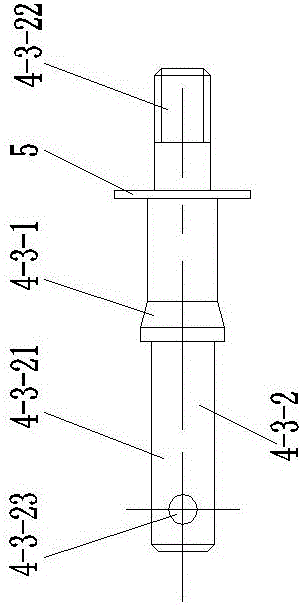

[0052] Such as Figure 9 , 10 11, a push rod armature structure of an electromagnetic reversing valve, including a push rod 4-3-2 and an armature 4-3, one end of the push rod 4-3-2 has a spool connecting section 4-3 -21, the other end of the push rod 4-3-2 has an armature connection section 4-3-22, and the valve core connection section 4-3-21 of the push rod 4-3-2 is provided with a push rod radial pin The hole 4-3-23, the armature connection section 4-3-22 of the push rod 4-3-2 has a left-hand thread, one end of the armature 4-3 has a left-hand screw hole, and the push rod 4-3 -2 The left-handed thread of the armature connecting section 4-3-22 is connected with the left-handed screw hole at one end of the armature 4-3 as a left-handed thread.

[0053] Such as Figure 9 , 10 , 11, the push rod 4-3-2 has a stopper 5 integrated with it, and the stopper 5 is offset against the armature 4-3, due to the integrated structure of the push rod and the stopper, On the one hand, the...

Embodiment 2

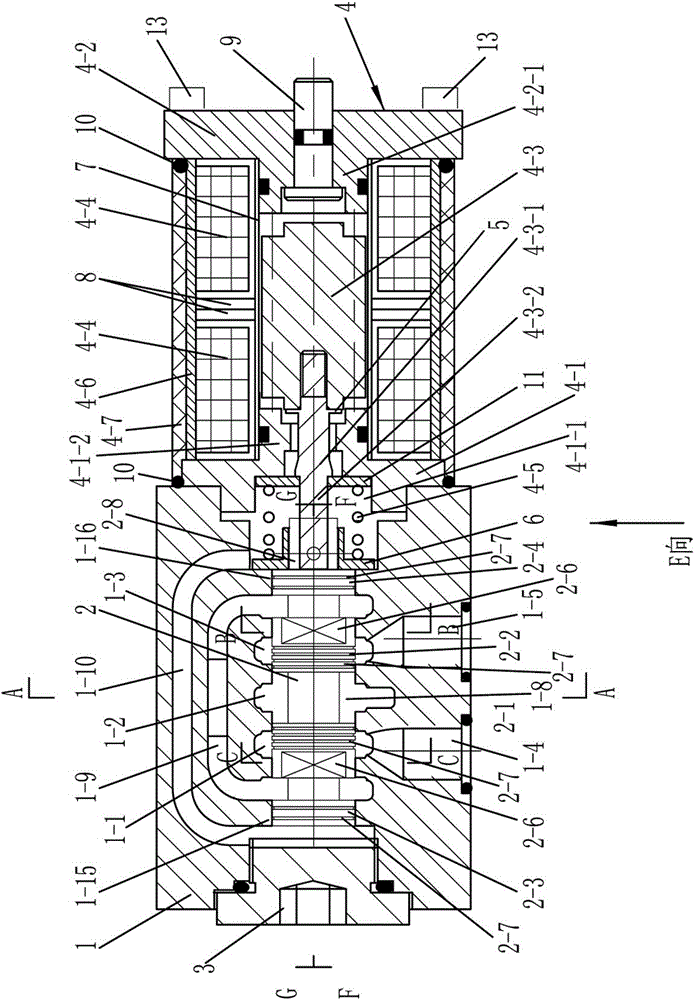

[0056] Such as Figure 1~20 As shown, an electromagnetic reversing valve includes a valve body assembly and an electromagnet assembly; the valve body assembly includes a valve body 1, a valve core 2 and a valve body end cover 3;

[0057] The valve body 1 includes a first oil port 1-4, a second oil port 1-5, an oil return port 1-6, an oil inlet port 1-7 and a valve body main hole 1-8 arranged along its axial direction , and the first oil passage 1-1, the second oil passage 1-2 and the third oil passage 1-3 arranged axially along the inner wall of the main hole 1-8 of the valve body, the first oil passage 1-4 It communicates with the first oil passage 1-1, the second oil port 1-5 communicates with the third oil passage 1-3, the oil inlet 1-7 communicates with the second oil passage 1-2, and the first The oil passage 1-1, the second oil passage 1-2 and the third oil passage 1-3 are all connected with the main hole 1-8 of the valve body;

[0058] The valve body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com