Silica sol-combined mullite perfusion material adapted to rapid repair of industrial furnace

A silica sol and mullite technology, which is applied in the field of refractory materials, can solve the problems of spalling, thermal shock resistance, stability, increased bulk density, and poor drainage channels, and achieves good thermal shock stability, good construction performance, and simplified construction. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

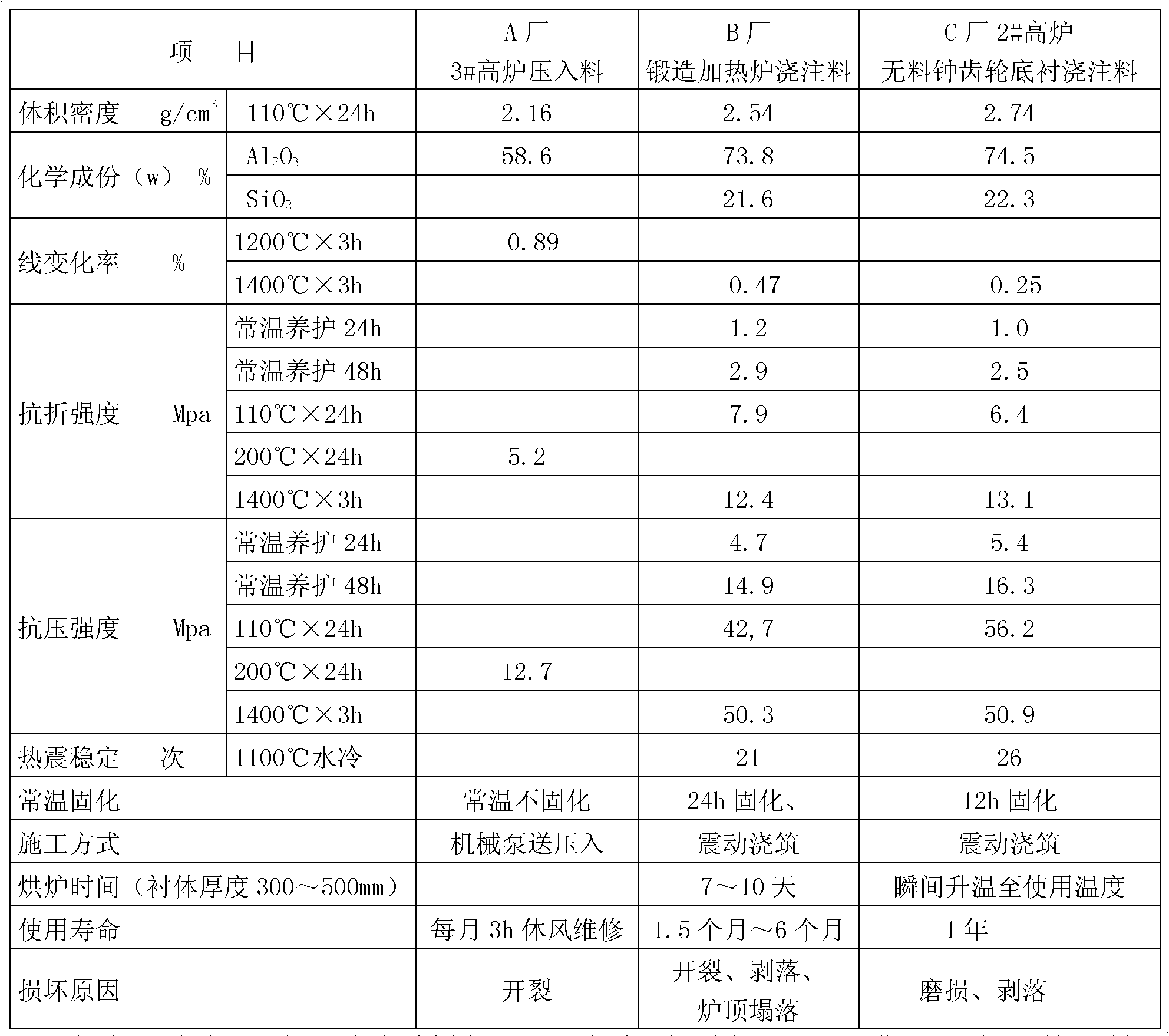

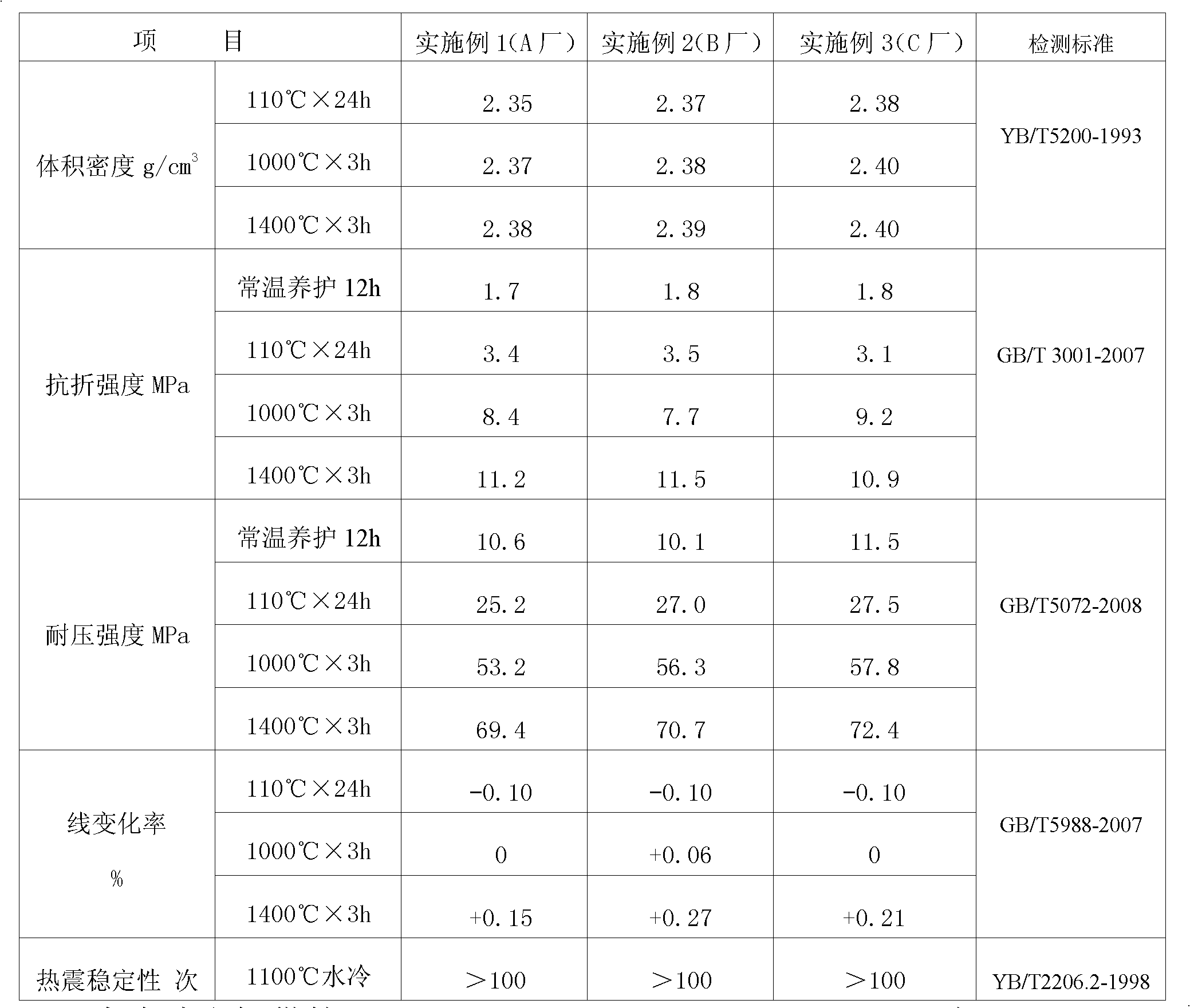

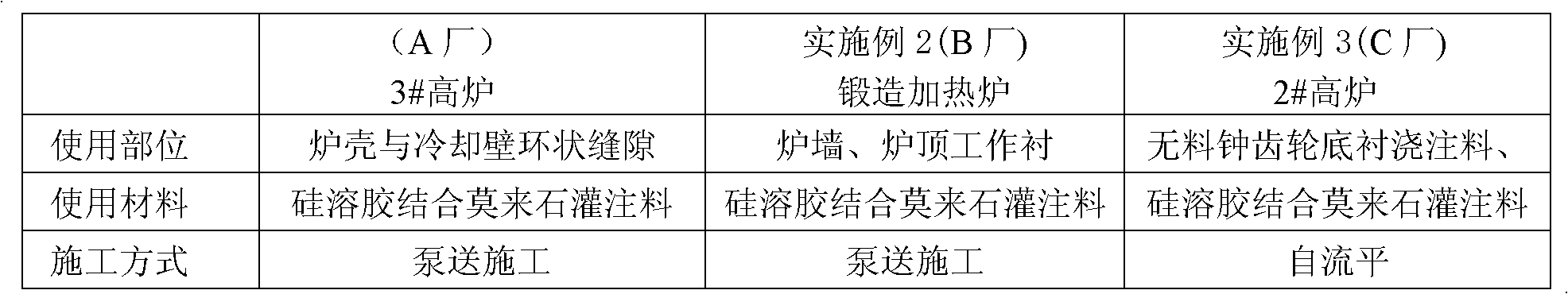

[0031] The specific implementation of the present invention will be further described in detail below in conjunction with the examples. Before the applicant made the present invention, a large number of problems existed in the existing technology, such as the annular gap between the blast furnace shell and the cooling wall, the short service life of the lining of industrial furnace equipment such as heating furnaces, and the emergency repair work, were carried out. The investigation and research are illustrated with examples.

[0032] The following are the performance and usage of the pressed-in material filled in the annular gap between the blast furnace shell and the stave produced by the three factories, the lining material of the forging heating furnace, and the castable for the emergency repair of the bottom lining of the bell gear without material.

[0033] Table 1. Performance and usage of blast furnace press materials, castables, and forging heating furnace castables i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com