Novel magnesium oxychloride cement mixed by water

A technology of magnesium oxychloride cement and bischofite, applied in the field of magnesium oxychloride cement, can solve the problem of low total heat release, achieve the effects of low heat of solution, easy availability of raw materials, and delay the time of intense heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 A new type of magnesium oxychloride cement mixed with water, the cement refers to 100 parts by weight (kg) of the partial pyrolysis product of bischofite and 1 part of organic acid - citric acid, mixed, powdered Grind to 180 mesh.

[0032] Among them: partial pyrolysis products of bischofite include magnesium oxide and anhydrous magnesium chloride, in which MgO and MgCl 2 The molar ratio is 6.83:1.

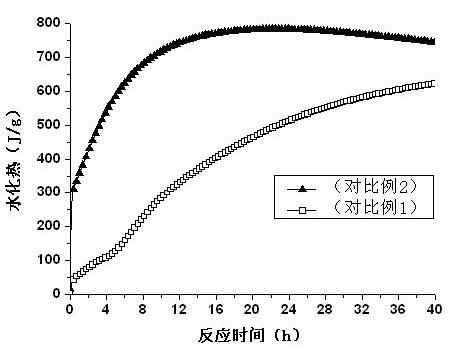

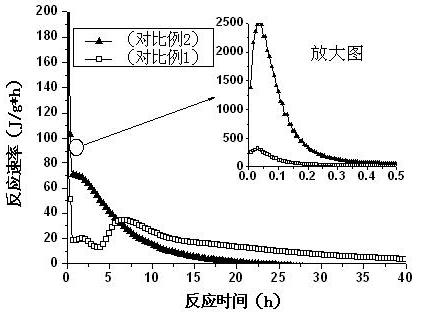

[0033] In control MgCl 2 with H 2 The hydration exotherm and intensity were tested at a molar ratio of O of 1:27 (see image 3 , Figure 4 , Figure 5 , Figure 6 ).

Embodiment 2

[0034] Example 2 A new type of magnesium oxychloride cement mixed with water, the cement refers to the partial pyrolysis product of 90 parts by weight (kg), 1 part of organic acid-citric acid and 10 parts of Active mixed material - fly ash is obtained by mixing and grinding to 180 mesh.

[0035] Among them: partial pyrolysis products of bischofite include magnesium oxide and anhydrous magnesium chloride, in which MgO and MgCl 2 The molar ratio is 8:1.

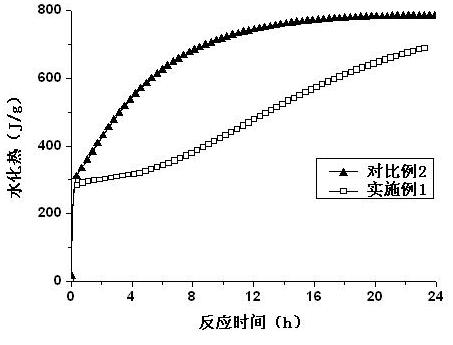

[0036] In control MgCl 2 with H 2 The hydration exotherm and intensity were tested at a molar ratio of O of 1:23 (see Figure 5 , Figure 6 ).

Embodiment 3

[0037] Example 3 A new type of magnesium oxychloride cement mixed with water, the cement refers to the partial pyrolysis product of 90 parts by weight (kg), 1 part of organic acid - citric acid, 10 parts of Active mixed material - fly ash and 3 parts of calcium dihydrogen phosphate are mixed and ground to 180 mesh.

[0038] Among them: partial pyrolysis products of bischofite include magnesium oxide and anhydrous magnesium chloride, in which MgO and MgCl 2 The molar ratio is 8:1.

[0039] In control MgCl 2 with H 2 The hydration heat and intensity were tested under the condition that the molar ratio of O was 1:23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com