Stainless steel composite steel pipe welding method

A welding method and composite steel pipe technology, applied in the field of steel pipe welding, can solve the problems of increased welding cost, low welding efficiency of manual welding, difficulty in ensuring the quality of root weld bead, etc., and achieve the effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The welding steps of the stainless steel clad steel pipe of the present invention will now be described in detail with reference to the accompanying drawings.

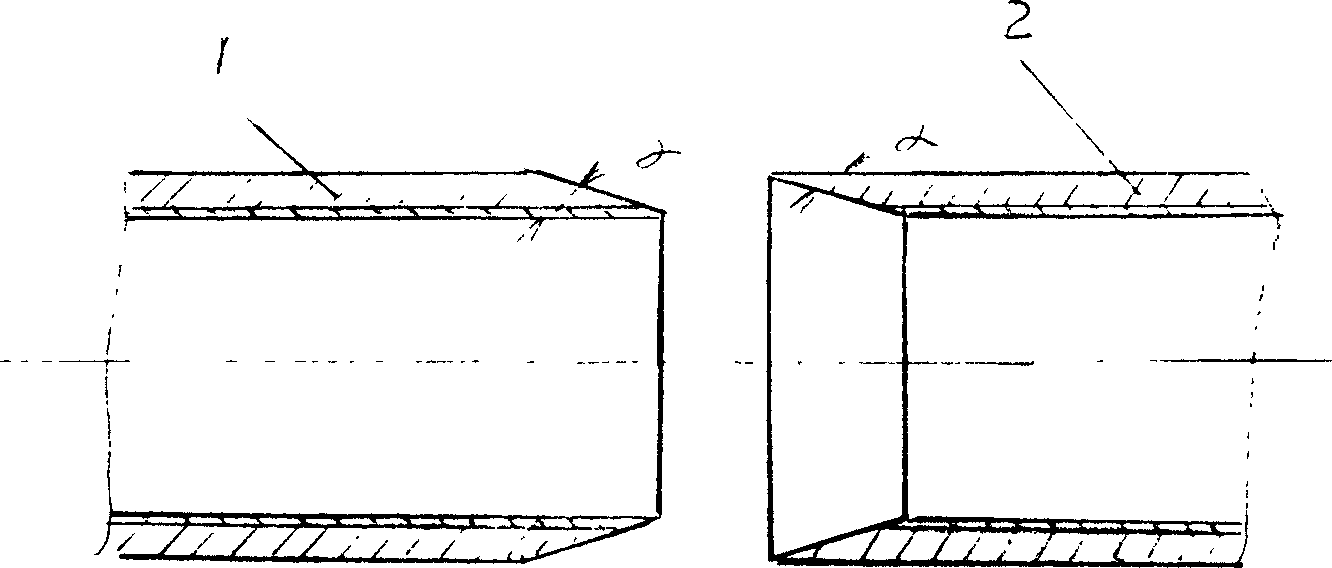

[0019] A. Machining the connection surfaces of stainless steel composite steel pipes 1 and 2 into a diagonal butt joint, such as figure 1 The bevel angle α is shown as 15°~20°. Clean the oil stains and oxides on the connecting surface and the adjacent pipe surface;

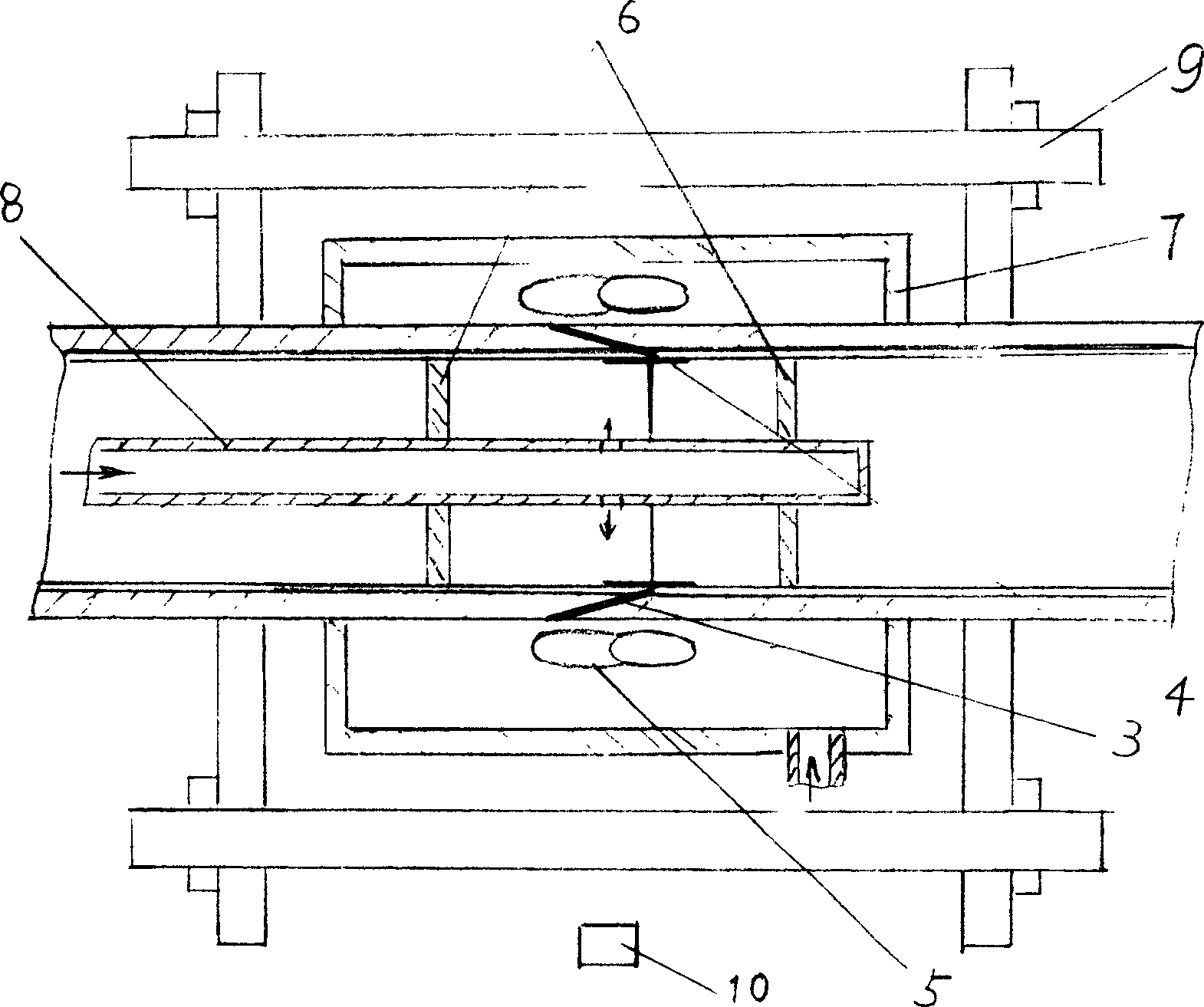

[0020] B. Place intermediate materials 3 and 4 on the connection surface and the adjacent pipe surface. The intermediate material is Ni-Cr-Si-B nickel-based material with strong diffusion ability, low melting point and good corrosion resistance.

[0021] C. Insert the convex pipe end 1 tightly into the concave pipe end 2 on the assembly clamping mechanism 9. After the induction heating coil 5 is placed near the connection surface, the two pipes are clamped and rigidly fixed together, so that when heated Unable to expand freely, the resulting therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com