Elastic circuit fabrication method based on metal sacrificial layer process

A technology of metal sacrificial layer and metal circuit, which is applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, and printed circuits. Difficulty, simplification of the process flow, and the effect of overcoming the problems of metal wire cracks and open circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

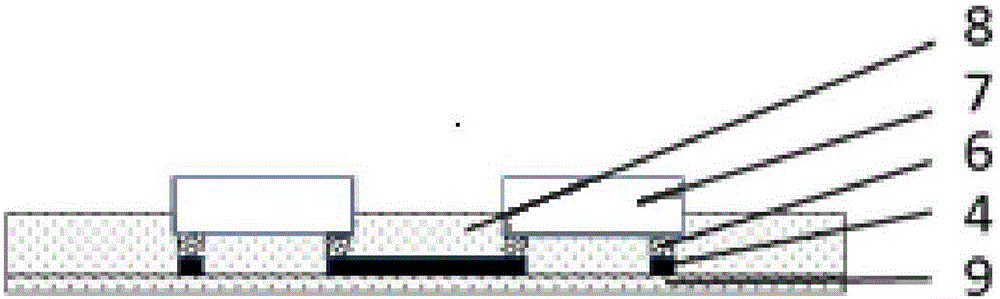

[0039] This embodiment relates to the preparation of elastic circuits based on the metal sacrificial layer technology and the prepared elastic circuits. The elastic circuit as figure 2 As shown, the material of the upper elastic polymer 8 is polydimethylsiloxane, and its thickness is 500 microns; the electronic component 7 is a single-chip microcomputer, a sensor or a capacitor resistor, etc.; the solder paste 6 is a low-temperature solder paste with a melting temperature of 130°C; The metal circuit and pad 4 are made of copper with a thickness of 10 microns and a line width of 100-4000 microns; the elastic polymer 9 of the lower layer is polydimethylsiloxane with a thickness of 100 microns.

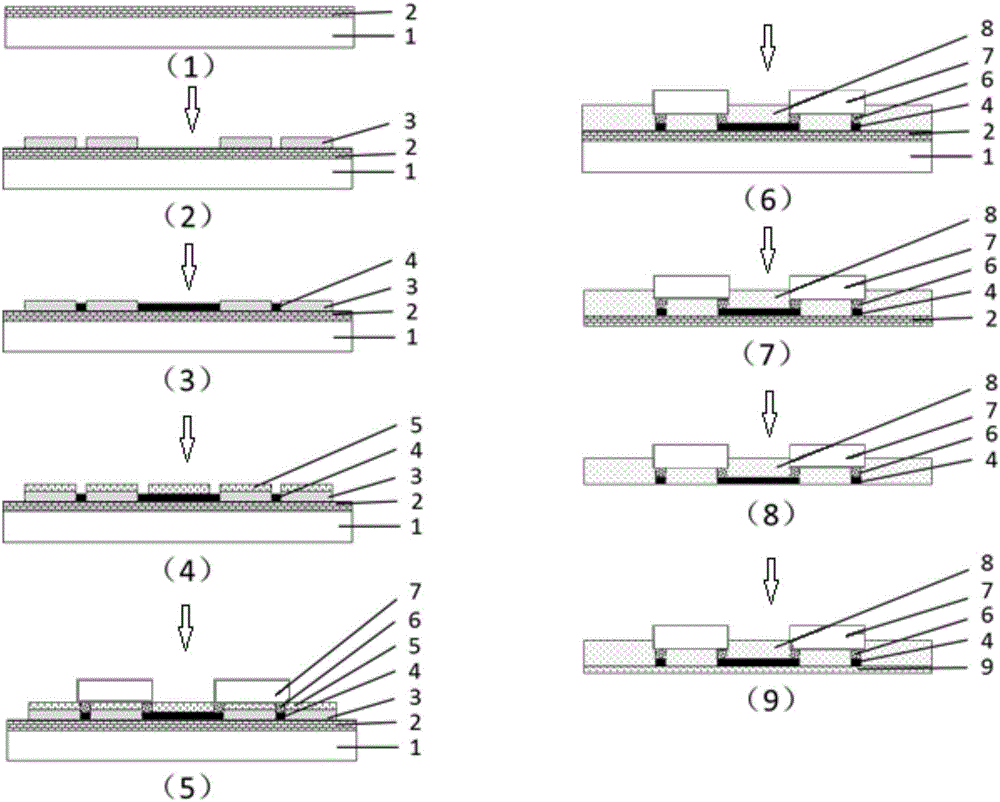

[0040] The elastic circuit preparation process based on the metal sacrificial layer process in this embodiment is as follows figure 1 As shown, including steps (1)-(9), specifically as follows:

[0041] (1) Make an aluminum thin film (metal thin film 2) and paste it on the glass subst...

Embodiment 2

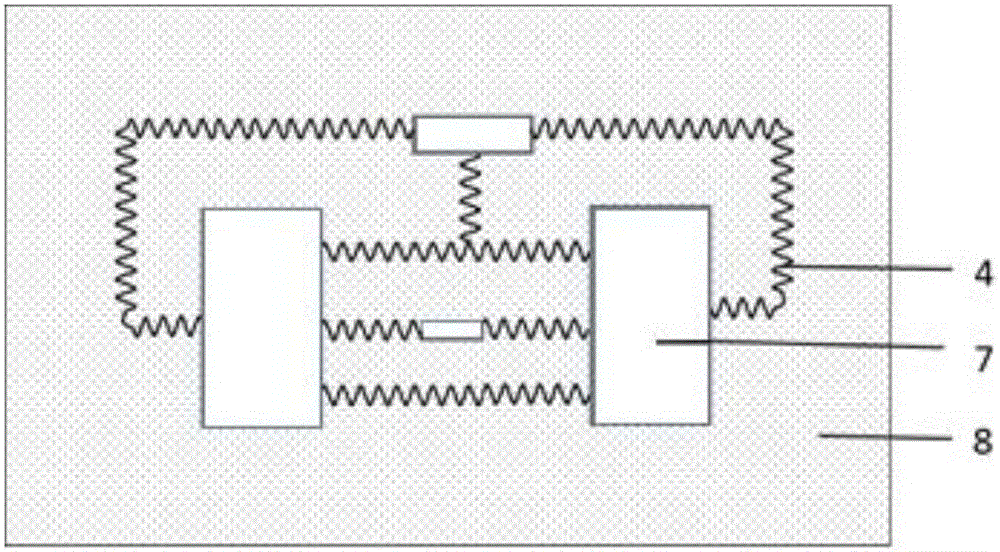

[0061] The elastic circuit preparation based on the metal sacrificial layer process and the elastic circuit prepared in this embodiment are the same as in embodiment 1, except that the material of the upper elastic polymer 8 is elastic silicone rubber with a thickness of 50 microns; The circuit and the pad 4 are snake-shaped, the material is gold, the thickness is 1 micron, and the line width is 10-100 microns; the lower elastic polymer 9 is elastic silicone rubber, and the thickness is 50 microns; the substrate used is a silicon substrate , the metal film used is a copper film with a thickness of 15 microns.

Embodiment 3

[0063] The elastic circuit preparation based on the metal sacrificial layer process and the elastic circuit prepared in this embodiment are the same as in embodiment 1, except that the material of the upper elastic polymer 8 is polydimethylsiloxane, and its thickness is 300 microns; the metal circuit and pad 4 are S-shaped, the material is silver, the thickness is 50 microns, and the line width is 1000-4000 microns; the lower elastic polymer 9 is elastic silicone rubber, and the thickness is 500 microns; the substrate used As the ceramic sheet substrate, the metal film used is an aluminum film with a thickness of 200 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com