12Cr1MoV alloy steel pipe welding method

A 12cr1mov, welding method technology, applied in the field of steel pipe welding, can solve the problems of cracks and penetration of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The welding steps of the 12Cr1MoV alloy steel pipe of the present invention are described in detail below:

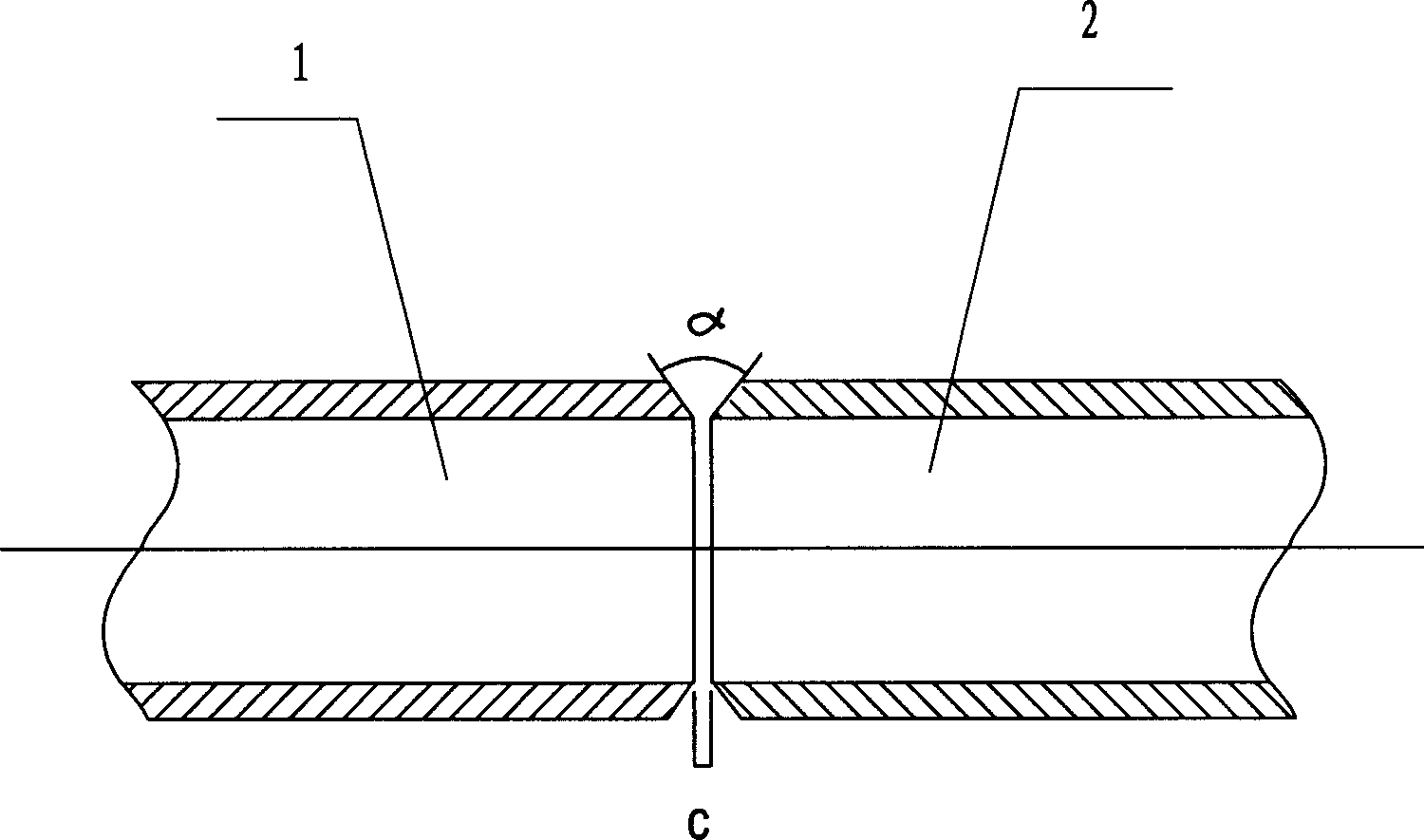

[0014] 1. The welding surfaces of the welded steel pipes 1 and 2 are machined into a groove form, such as figure 1 As shown, the oblique angle α is 60±3°, the gap c is 2.5-3.0mm, and the welding surface and nearby steel pipes are cleaned of oil, rust and other contaminants.

[0015] 2. Use a fixture to fix the two-phase welded steel pipe.

[0016] 3. Set a heating device such as a crawler heater near the weld to heat the steel pipe near the weld to 250-350℃.

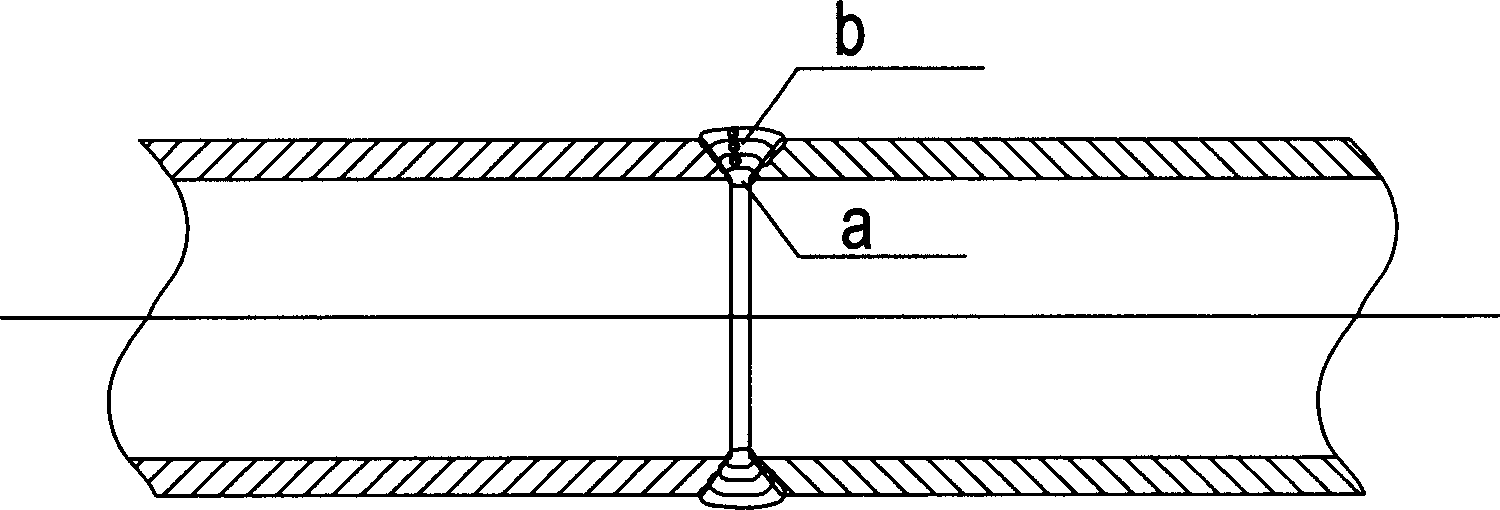

[0017] 4. Heat preservation, and use H08CrMoVA welding wire argon arc welding for bottom welding, such as figure 2 shown at a.

[0018] 5. Manually weld several layers with A242 stainless steel electrode, such as figure 2 As shown in b in the middle, the slag and spatter between the welding layers should be removed, and the welding temperature between the layers should not be lower than 250 °C.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com