Method for producing rigid foam polyurethane heat-insulation and decorative integrated plate

A technology of rigid polyurethane foam and production method, which is applied in the direction of covering/lining, construction, building structure, etc. It can solve the problems of cumbersome layer-by-layer construction, low impact strength, and easy cracking of rigid plastering layers, and achieve saving Production cost and construction cost, improvement of weather resistance and stability, effect of enriching designs and uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

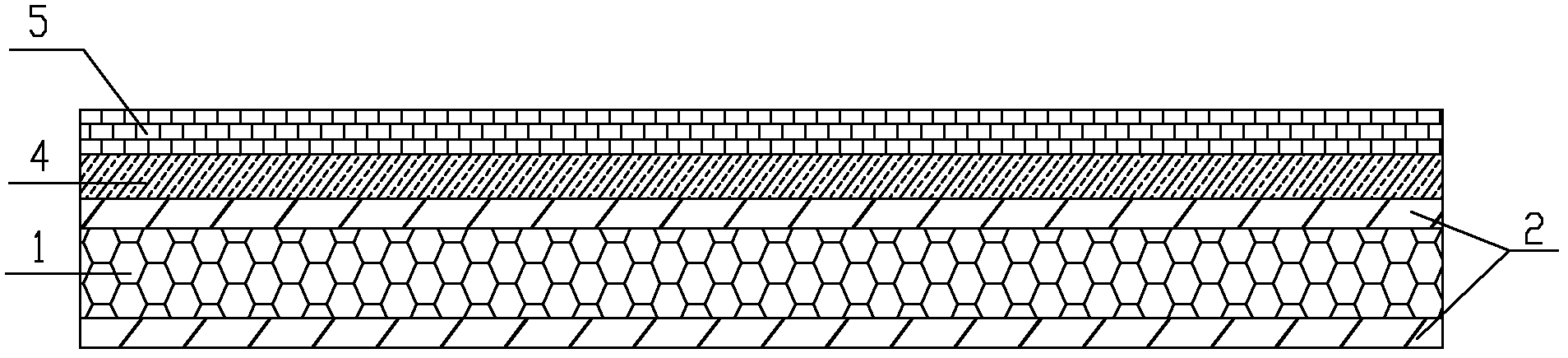

[0019] like figure 1 As shown, the rigid polyurethane thermal insulation and decoration integrated board produced by the present invention according to the production method is composed of five layers:

[0020] From one side of the board to the other side are facing layer 5, polymer cement enclosure layer 4, polymer cement coil layer 2, rigid foam polyurethane layer 1, and polymer cement coil layer 2, among which the polymer cement enclosure layer 4 and the facing layer 5 are provided with grid cloth.

[0021] The production method is as follows: in the first step, the polymer cement mortar prepared by blending cement, polyacrylic acid emulsion, river sand, TCPP and appropriate amount of water is produced on the alkali-resistant glass fiber felt through the coil production line to produce the polymer cement coil. The roll is ready for use; the second step is to unroll the polymer cement coiled material on the coiled material line and spread the mesh cloth on it, mix it with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com