Production process of sponge-structured high-elasticity non-woven three-dimensional cotton

A production process, three-dimensional technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor resilience and softness, poor effect, etc., and achieve excellent compression resistance and air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

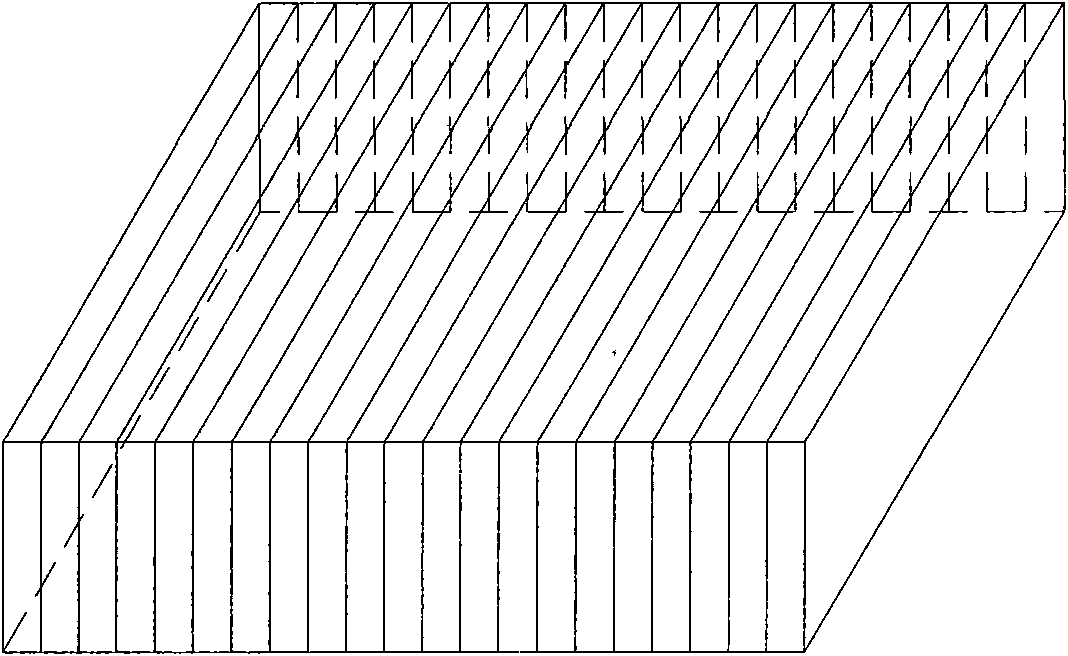

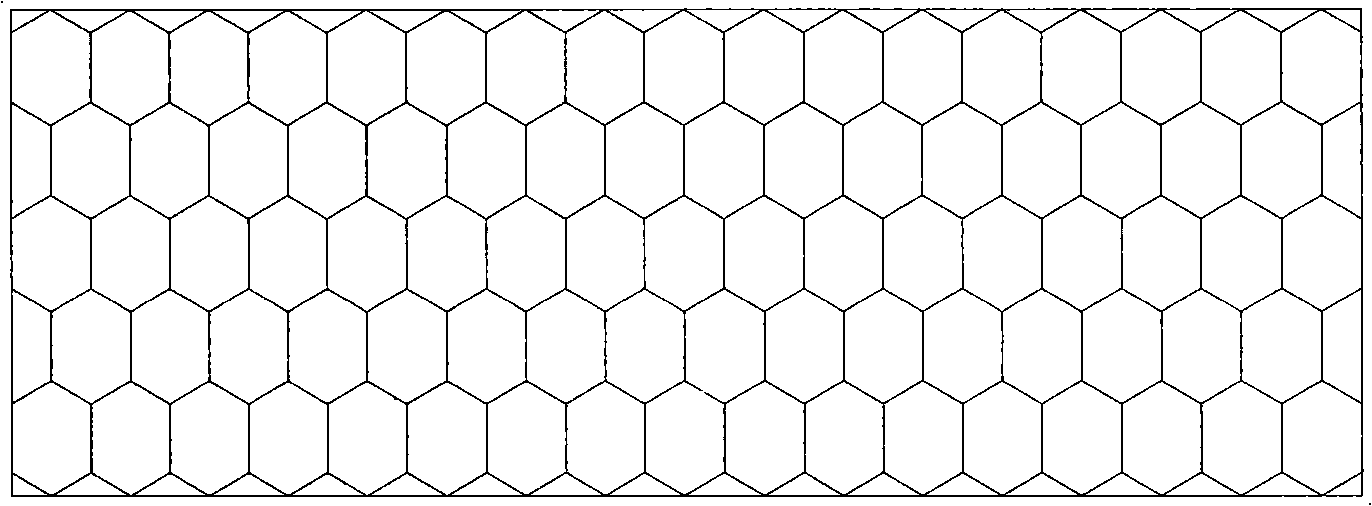

[0015] refer to image 3 , Figure 4 As shown, the present invention discloses a production process of a sponge-like structure highly elastic non-woven three-dimensional cotton, comprising the following steps: modifying polyester staple fibers with high elasticity and low melting point, heat-shrinkable modified polyester staple fibers and other After the fibers are mixed in proportion, they are opened by the opener, and sent to the cotton feeder through the cotton conveying fan, and the cotton feeder is fed to the carding machine for carding to form a continuous fiber web, and the above fiber web is fed to the vertical laying machine. The forming machine carries out vertical forming processing, and is sent to the oven for heat setting through the oven conveying mesh belt, and then formed by cooling and setting and slitting and rolling to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com