Vamp material and method for preparing same

A technology for fabrics, shoes and boots, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. The effect of peeling damage resistance, waterproof and bending resistance improvement, and folding resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

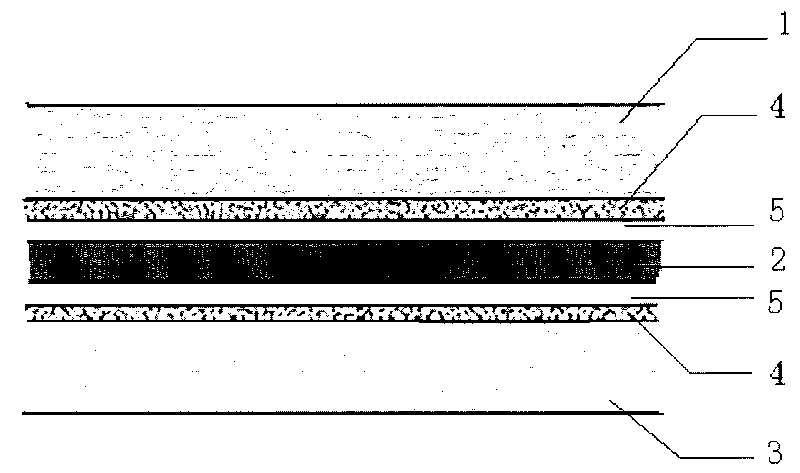

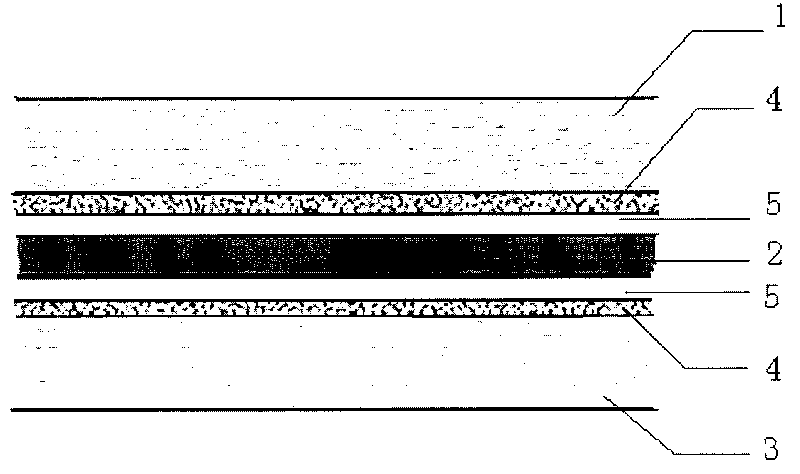

Image

Examples

Embodiment Construction

[0019] In one embodiment of the present invention, the process steps of making shoe fabrics are:

[0020] a) Pass the warp-knitted cotton cloth through an aqueous solution containing 1.5% nano-silver anti-mold and antibacterial agent, dry it at 200° C., and wind it up after moisture absorption and perspiration and shaping pulp edge treatment to obtain a good anti-mold and antibacterial warp-knitted cotton cloth ;

[0021] b) Add 2% nano-silver anti-mold and antibacterial agent and appropriate amount of lubricant to the polytetrafluoroethylene micropowder, sieve after mixing, mature, compact, push, extrude, calender (base band), and base band longitudinal stretching (degreasing), transverse stretching (expansion) steps, obtain polytetrafluoroethylene film; The double-sided coating of polytetrafluoroethylene film contains the polyurethane adhesive of 5% anionic surfactant and 12% blowing agent, and consumption is 50g / m 2 , after drying at 140-150°C, wind up to obtain an antiba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com