Hard-foam polyurethane-expanded and vitrified microbead composite heat insulation flame-retardant board and preparation method thereof

A technology of expanded vitrified microbeads and rigid foamed polyurethane, which is applied in the field of building materials, can solve the problems of damage to the foam, decreased thermal insulation performance, and reduced thermal insulation performance, and achieves high production efficiency, good uniformity, and improved flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

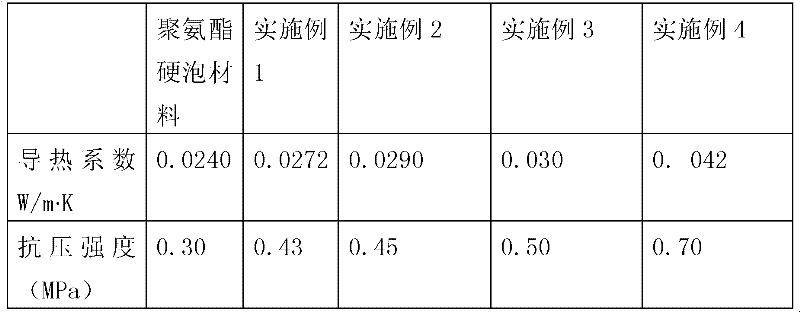

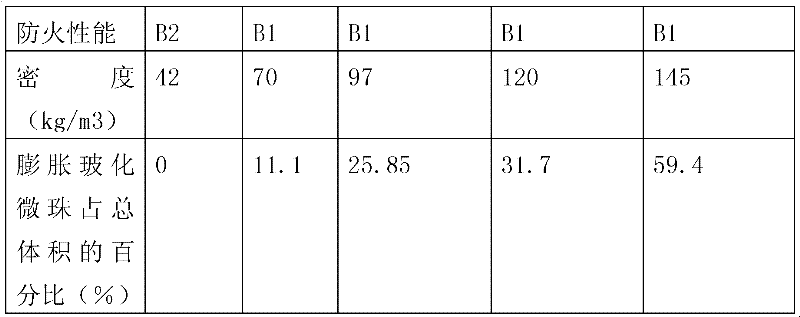

Embodiment 1

[0020] 16g of expanded vitrified microbeads with an average particle diameter of 0.1mm are surface-activated with 0.5g of silane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane, and then the expanded vitrified microspheres are mixed with 60g Polyurethane A material (polyisocyanate composite material) is mixed, after mixing evenly, then add 50g of polyurethane B material (polyether polyol composite material) and mix, after mixing uniformly, cast, obtain the hard foam of the present invention after molding Polyurethane-expanded vitrified microbead composite thermal insulation and flame retardant board. Or further, cut it according to the needs of use.

Embodiment 2

[0022] First, 32g of the expanded vitrified microspheres with an average particle diameter of 0.5mm were used with 0.16g of silane coupling agent

[0023] γ-(Methacryloyloxy)propyltrimethoxysilane is used for surface activation, and then the expanded vitrified microspheres are mixed with 50g of polyurethane material B. After mixing evenly, 60g of material A polyurethane is added for mixing. After casting and molding, the rigid foam polyurethane-expanded vitrified microsphere composite thermal insulation and flame-retardant board of the present invention is obtained.

Embodiment 3

[0025] First, 40g of the expanded vitrified microspheres with an average particle diameter of 1.0mm are surface-activated with 0.1g gamma-mercaptopropyltrimethoxysilane, then the expanded vitrified microspheres are mixed with 65g of polyurethane material A (mixed uniformly, then Add 50g of polyurethane material B for mixing, mix evenly and then cast, and after molding, the rigid polyurethane foam-expanded vitrified microbead composite thermal insulation and flame-retardant board of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com