Expanded perlite-polyurethane composite insulating board and manufacturing technique thereof

A technology of expanded perlite and composite thermal insulation, which is applied in the field of building energy conservation, can solve the problems of affecting the service life of the thermal insulation system, affecting the indoor living environment, and low water vapor transmission rate, and is conducive to industrialization and application. The effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Ordinary expanded perlite particles with a particle size of 2 mm are sent into the rotating drum, and polyurethane adhesive is sprayed into the rotating drum at the same time, the mass of polyurethane adhesive: the mass of expanded perlite = 0.8:1. The expanded perlite is continuously stirred in the drum to fully contact with the mist of polyurethane adhesive, discharged from the discharge port, put into a mold of a certain size, vibrated and flattened, hardened at 60°C for 4 hours, the mold frame is removed, and the cutting machine immediately The green body is cut to obtain the expanded perlite-polyurethane composite insulation board.

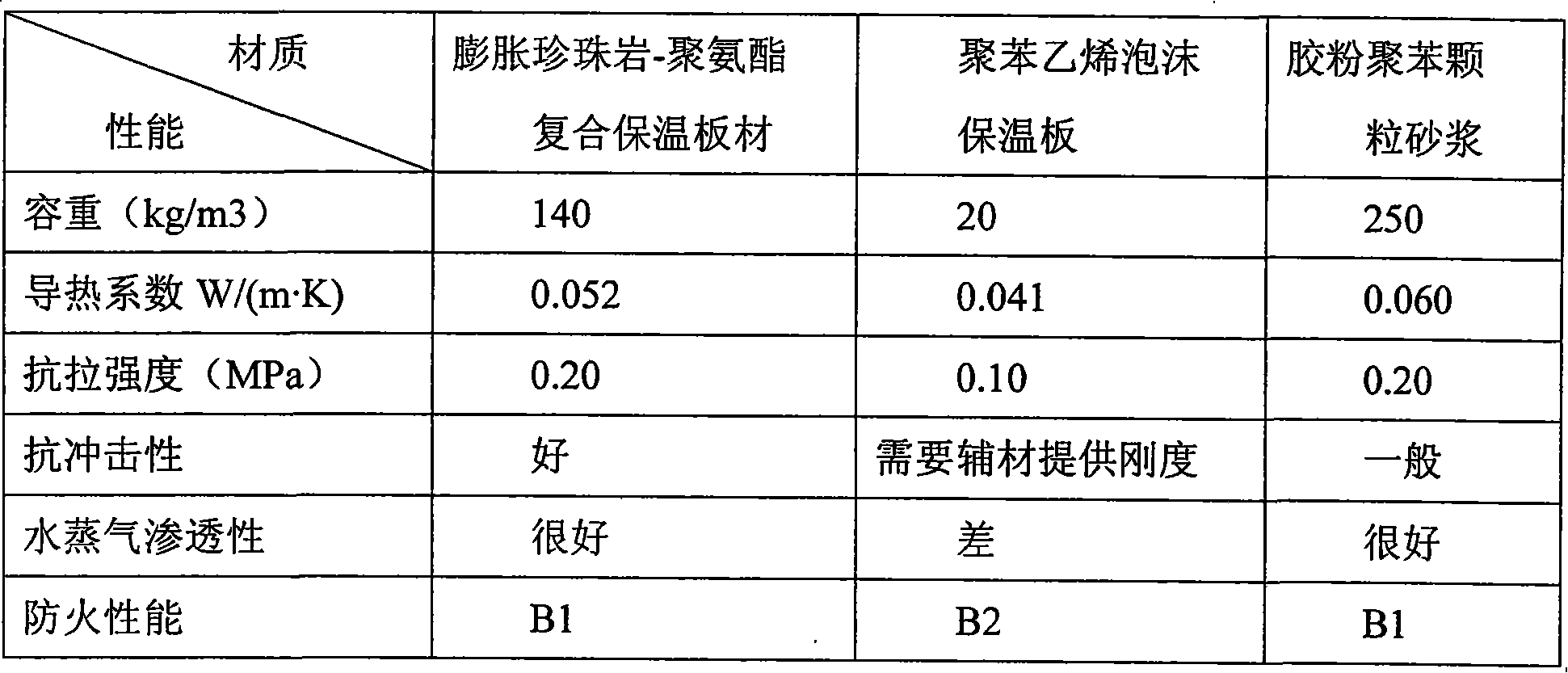

[0021] The performance comparison of the expanded perlite-polyurethane composite insulation board with polystyrene foam insulation board and mortar insulation materials is as follows:

[0022]

[0023] It can be seen from the above table that although the thermal conductivity of the new expanded perlite-polyurethane composite insula...

Embodiment 2

[0026] Ordinary expanded perlite with a certain particle size distribution is put into a stirring tank, and polyurethane adhesive is sprayed while stirring, the quality of polyurethane adhesive: the quality of expanded perlite = 1.5:1. The expanded perlite is continuously stirred in the mixing tank and fully contacted with the polyurethane adhesive mist. After mixing evenly, it is put into a mold of a certain size, shaken and flattened, hardened at 90°C for 2 hours, the mold frame is removed, and the cutting machine is ready for blanking. The body is cut, and the expanded perlite-polyurethane composite insulation board is obtained.

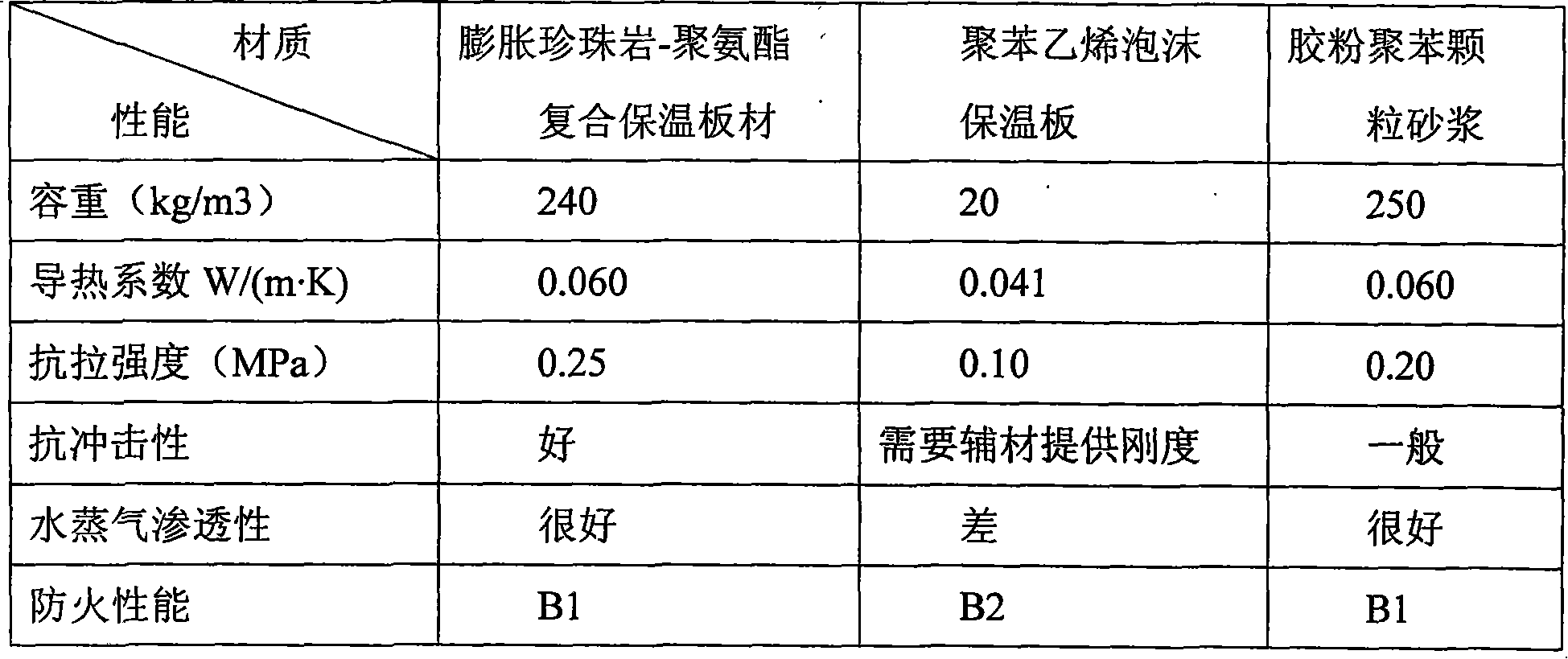

[0027] The performance comparison of the expanded perlite-polyurethane composite insulation board with polystyrene foam insulation board and mortar insulation materials is as follows:

[0028]

[0029] This method is a batch production process. The thermal conductivity of the expanded perlite-polyurethane composite insulation board produced by...

Embodiment 3

[0032] The ordinary expanded perlite with a particle size of 8 mm is sent into the rotating drum, and the foamed polyurethane adhesive is sprayed into the drum at the same time, the mass of the foamed polyurethane adhesive: the mass of the expanded perlite = 1:1. The expanded perlite is continuously stirred in the drum to fully contact with the foamed polyurethane adhesive, discharged from the discharge port, put into a mold of a certain size, vibrated and flattened, hardened at 40°C for 20 hours, the mold frame is removed, and the cutting machine That is, the green body is cut, and the expanded perlite-polyurethane composite insulation board is obtained.

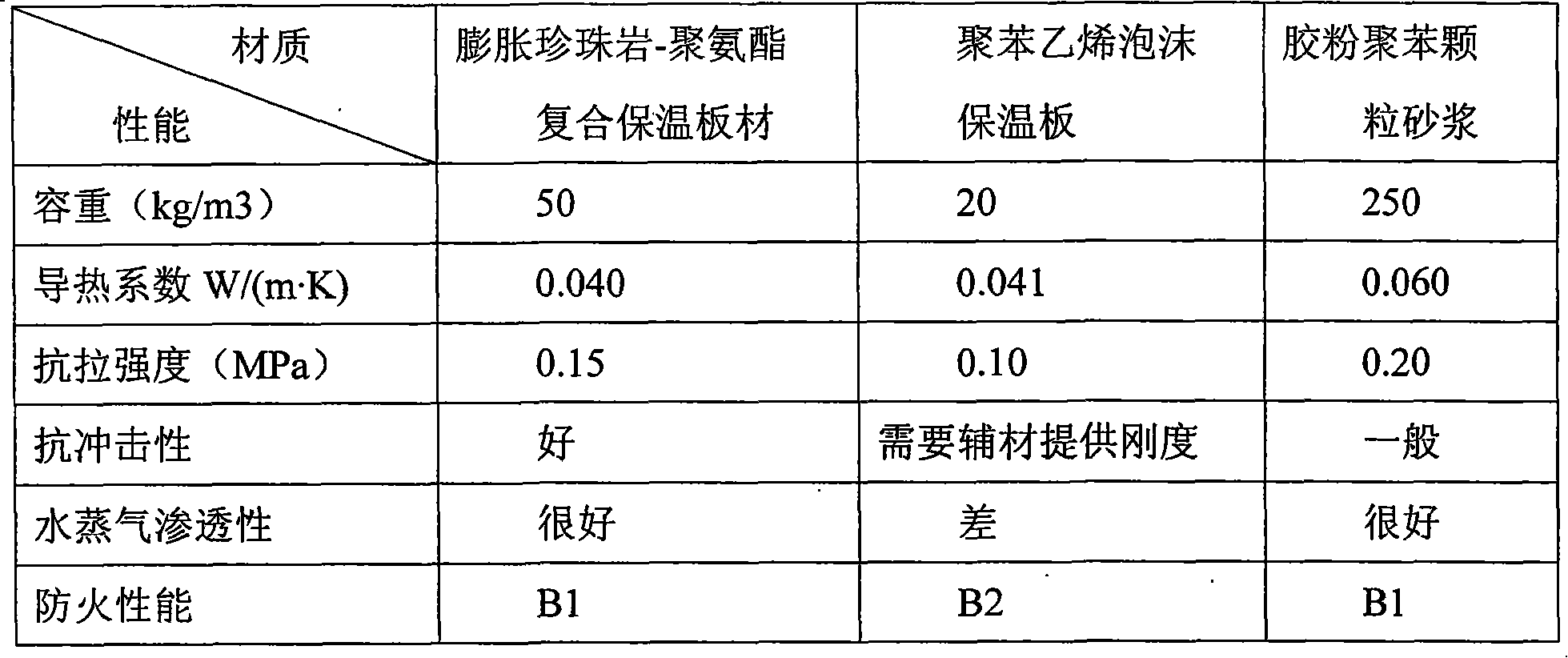

[0033] The performance comparison of the expanded perlite-polyurethane composite insulation board with polystyrene foam insulation board and mortar insulation materials is as follows:

[0034]

[0035] The thermal conductivity of the expanded perlite-polyurethane composite insulation board produced by this method is simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com