Method for reducing content of polyethylene wax during ethylene oligomerization reaction

A polyethylene wax and ethylene oligomerization technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of activity loss, activity reduction, light products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

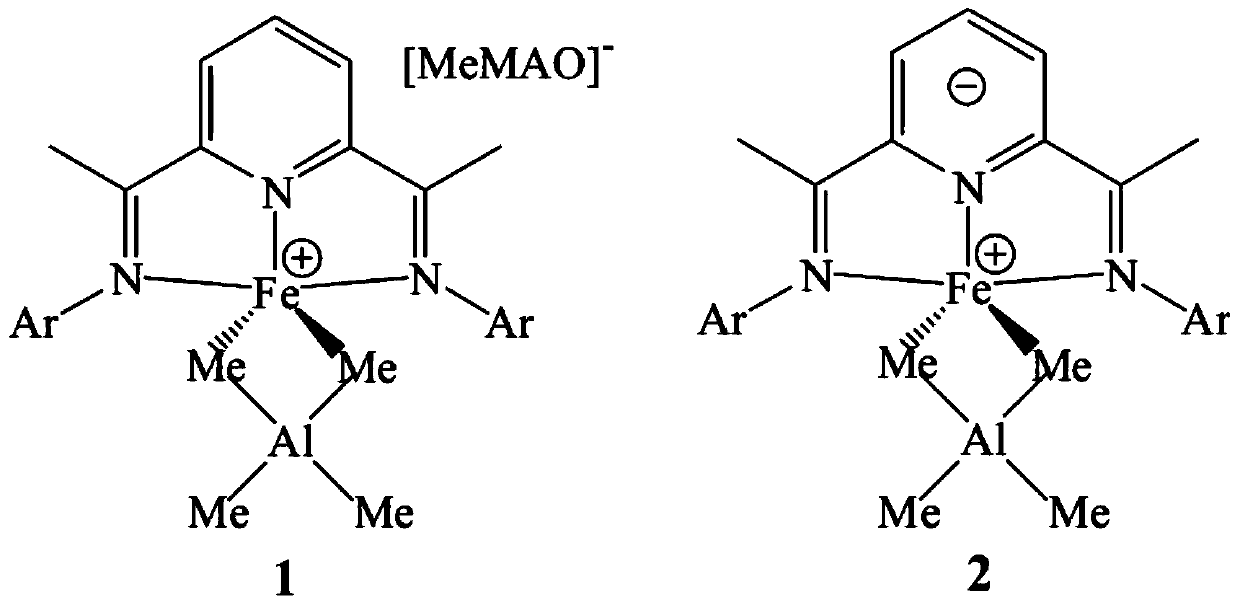

AI Technical Summary

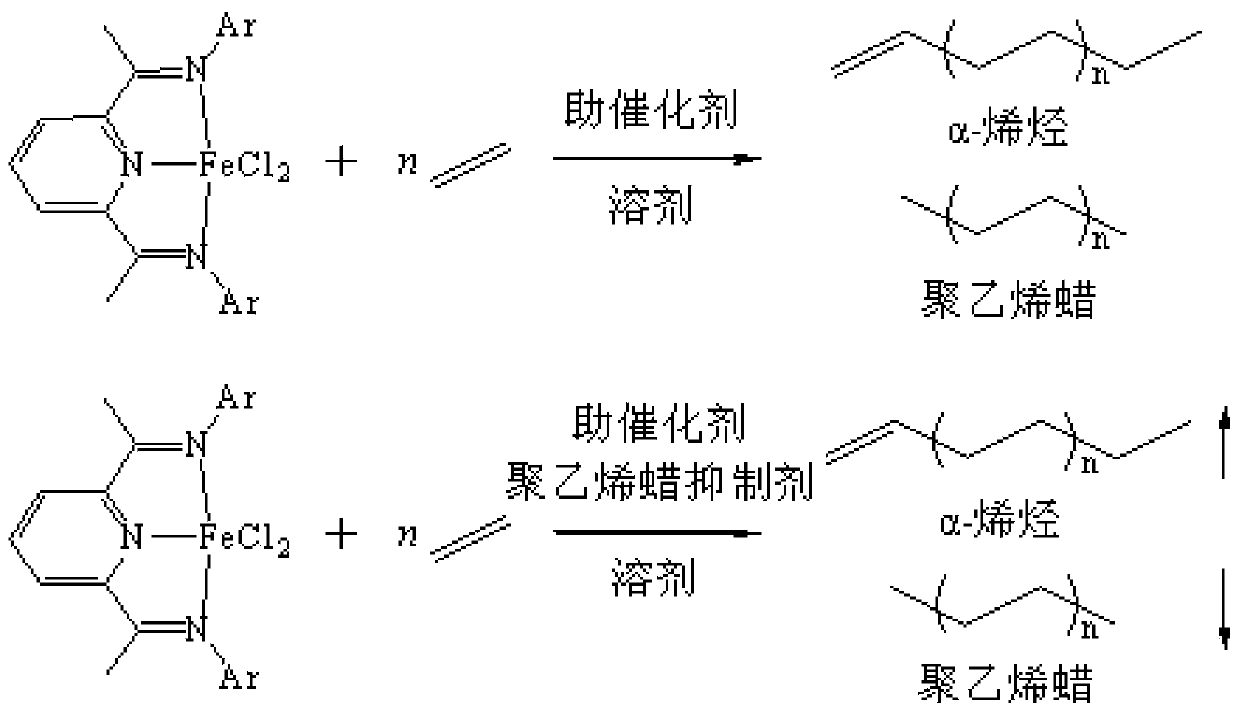

Problems solved by technology

Method used

Image

Examples

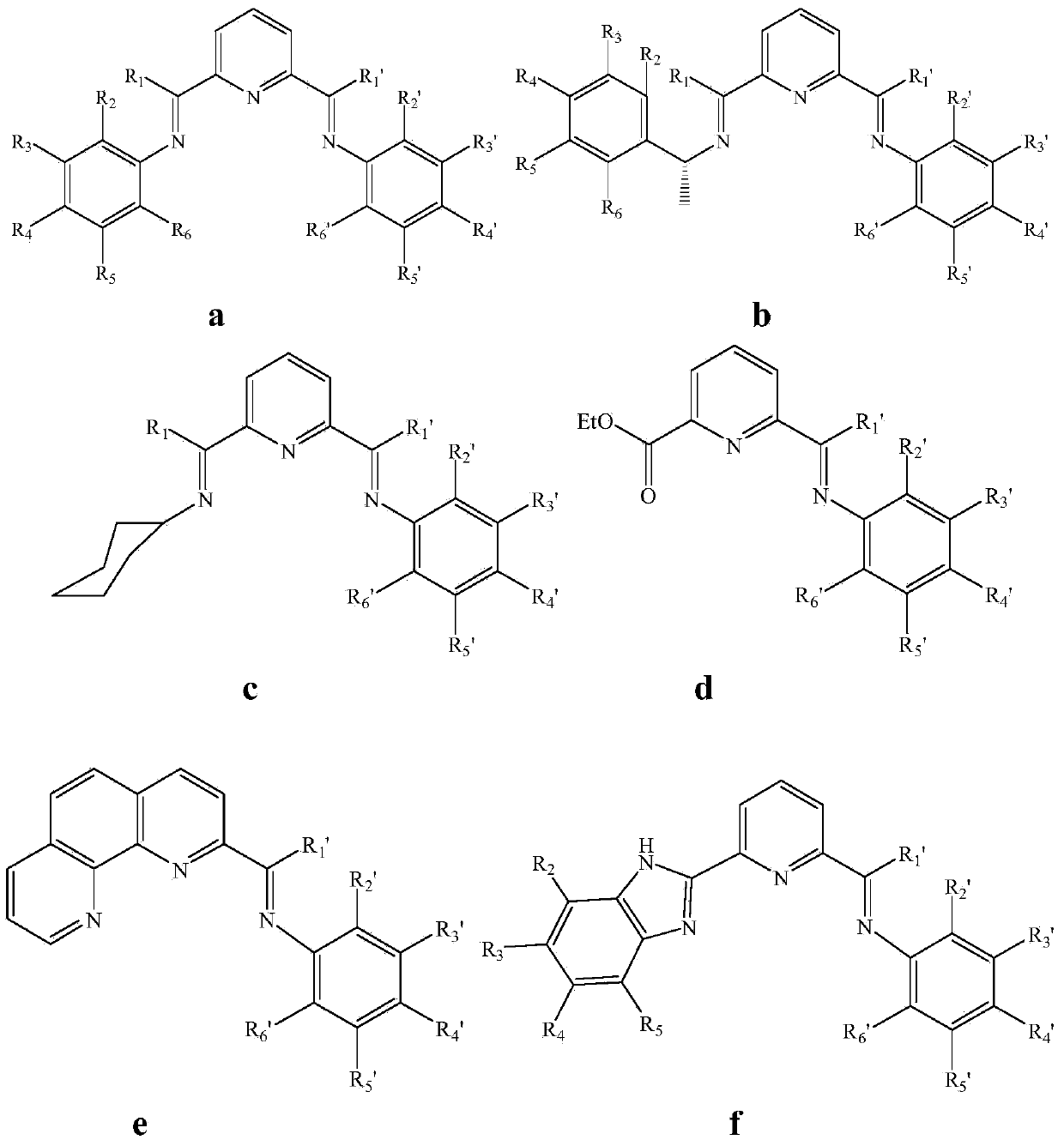

Embodiment 1

[0050] Under the protection of nitrogen, the pyridine bis-imine ligand L{2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]} shown in formula a and chlorinated After iron is blended in a molar ratio of 1:1, a catalyst represented by formula a' is obtained. dubbed into 2×10 -6 mol / ml suspension of main catalyst in toluene. The cocatalyst methylaluminoxane (MAO) is a 10wt% toluene solution, and the concentration of the substance is about 1.5mol / L. The polyethylene wax inhibitor is tetraethyl silicate (TEOS).

[0051] The structural formula of 2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]:

[0052]

[0053]A 250ml oligomerization reactor was heated to 90°C, and vacuum-baked for 2 hours, during which it was replaced three times with high-purity nitrogen and three times with polymer-grade ethylene. The temperature of the reactor was adjusted to a reaction temperature of 50° C. by circulating jacketed cooling water, and 50 ml of toluene was added as a reaction medium. S...

Embodiment 2

[0057] Add a certain amount of polyethylene wax inhibitor TEOS with a molar ratio of Si:Al=1.0, and other operations are the same as in Example 1.

[0058] After the gas-liquid-solid separation of the reaction product, the polyethylene wax was dried and weighed to obtain 0.39g; the liquid phase α-olefin product was analyzed by chromatography to obtain 3.11g; the content of polyethylene wax in the total product was 11.1wt.%. The activity of polyethylene wax is 0.39×10 6 g / mol Fe / h, α-olefin activity is 3.11×10 6 g / mol Fe / h.

Embodiment 3

[0060] Add a certain amount of polyethylene wax inhibitor TEOS with a molar ratio of Si:Al=3.0, and other operations are the same as in Example 1.

[0061] After the gas-liquid-solid separation of the reaction product, the polyethylene wax was dried and weighed to obtain 0.27g; the liquid-phase α-olefin product was analyzed by chromatography to obtain 3.41g; the content of polyethylene wax in the total product was 7.3wt.%. The activity of polyethylene wax is 0.27×10 6 g / mol Fe / h, α-olefin activity is 3.41×10 6 g / mol Fe / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com